Composite binder for repairing of pits in asphalt pavement and preparation method of composite binder

An asphalt pavement and binder technology, which is applied in the field of asphalt composite modification, can solve the problems of poor high temperature shear resistance, insignificant bonding effect, and reduced material viscoelasticity, so as to reduce the secondary damage rate and shorten traffic. The effect of controlling time and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

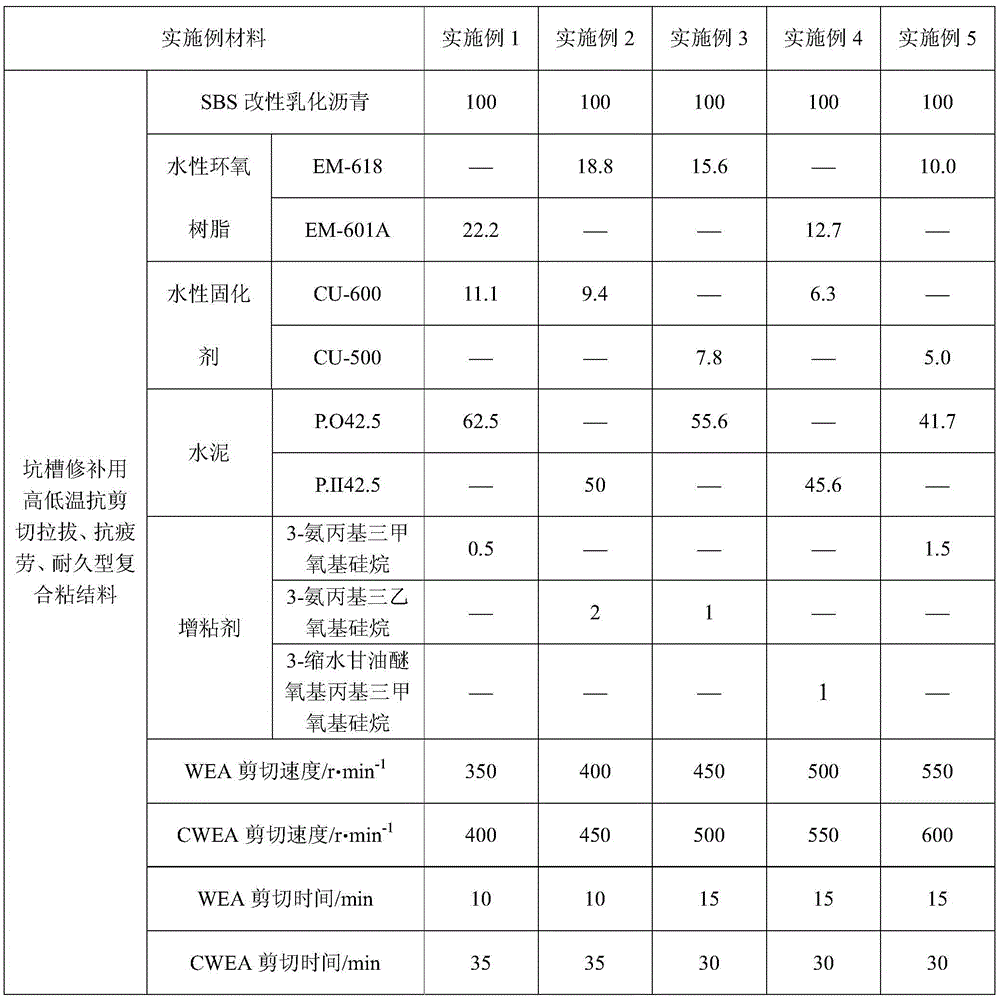

[0027] The preparation method of the composite binder for asphalt pavement pothole repair of the present invention comprises the following steps:

[0028] A. First mix 100 parts of SBS modified emulsified asphalt and 10-22.2 parts of water-based epoxy resin compound solution (CU-600 or CU-500 water-based epoxy curing agent) with a mass ratio of 5-11.1 parts of water-based curing The agent (CU-600 or CU-500 water-based epoxy curing agent) is accurately weighed according to the specified ratio, and the stator speed is adjusted to 350-550r / min with a high-speed shear emulsifier, and the shear time is 10-15min. Adhesive base fluid for repair with excellent bonding strength (WEA type);

[0029] B. The repair binder base liquid obtained in step A, 41.7-62.5 parts of cement (one of Portland cement and ordinary Portland cement), and 0.5-2 parts of silane coupling agent are mixed by mass ratio (One of 3-aminopropyltrimethoxysilane, 3-aminopropyltriethoxysilane, and 3-glycidyloxypropyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com