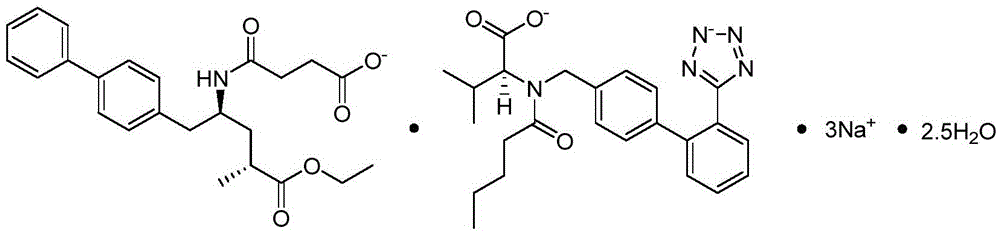

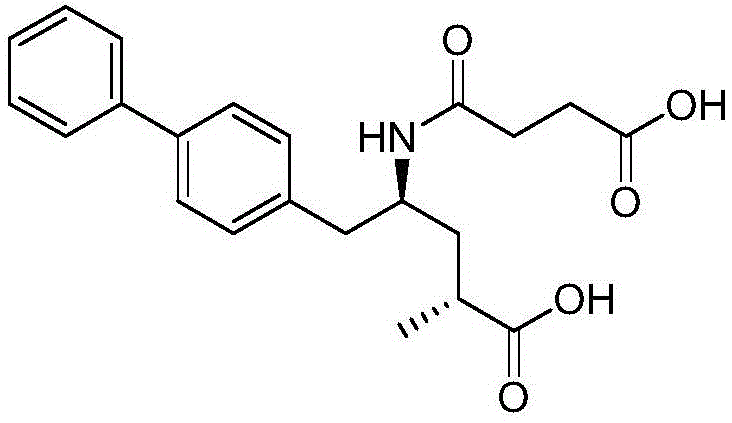

Refining method for enkephalin enzyme inhibitor and angiotensin II receptor antagonist eutectic compound

An angiotensin and receptor antagonist technology, applied in the field of medicine, can solve the problems of unstable quality of the final product LCZ696, and achieve the effects of high product yield, improved purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

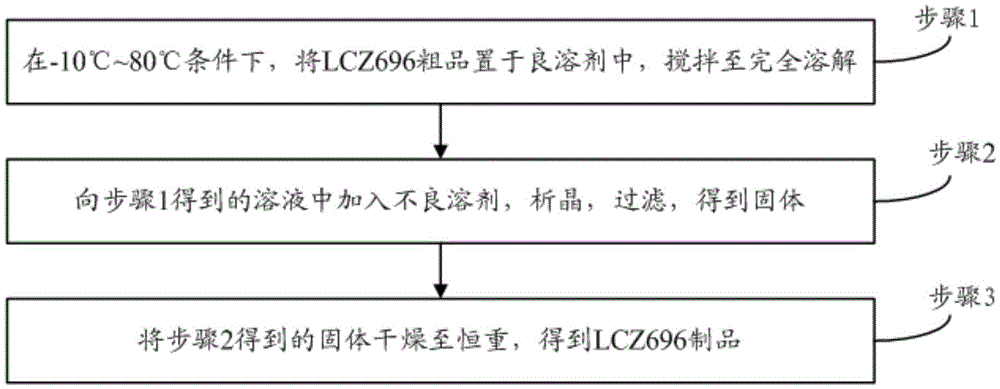

Method used

Image

Examples

Embodiment 1

[0032] (1) Take a certain amount of LCZ696 crude product and add methanol, stir at 55°C until completely dissolved, then add toluene in batches; wherein, the weight ratio of LCZ696 crude product, methanol and toluene is 1:5:200;

[0033] (2) Put the solution obtained in step 1 into a clean crystallizer, cool down to 0°C, and after a small amount of crystals are precipitated, stir and crystallize at 45°C for 12 hours;

[0034] (3) Filtration, drying the solid obtained by filtration under reduced pressure at 35° C. to constant weight to obtain a purified product with a yield of 88.9%.

Embodiment 2

[0036] (1) Take a certain amount of LCZ696 crude product and add ethanol, stir at 40°C until completely dissolved, then add n-heptane in batches; wherein, the weight ratio of LCZ696 crude product, ethanol and n-heptane is 1:5:200;

[0037] (2) Put the solution obtained in step 1 into a clean crystallizer, cool down to -10°C, and after a small amount of crystals are precipitated, stir and crystallize at 33°C for 12 hours;

[0038] (3) The solid obtained by filtration was dried under reduced pressure at 35° C. to constant weight to obtain a purified product with a yield of 90.5%.

Embodiment 3

[0040] (1) Take a certain amount of LCZ696 crude product and add n-propanol, stir at -10°C until completely dissolved, then add isopropyl acetate; among them, the weight ratio of LCZ696 crude product, n-propanol and isopropyl acetate is 1:5:300 ;

[0041] (2) Put the solution obtained in step 1 into a clean crystallizer, add seed crystals, and after a small amount of crystals are precipitated, stir and crystallize at 25°C for 12 hours;

[0042] (3) centrifugation, drying the solid obtained by centrifugation under reduced pressure at 35° C. to constant weight to obtain a purified product with a yield of 93.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com