Supported double-metal cyanide catalyst and preparation method and application thereof

A double metal cyanide and catalyst technology, applied in the field of catalytic materials, can solve the problem that the copolymerization product cannot take into account high carbonate unit content, low cyclic carbonate content, and low molecular weight distribution at the same time, so as to promote amorphousness and facilitate separation , Improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

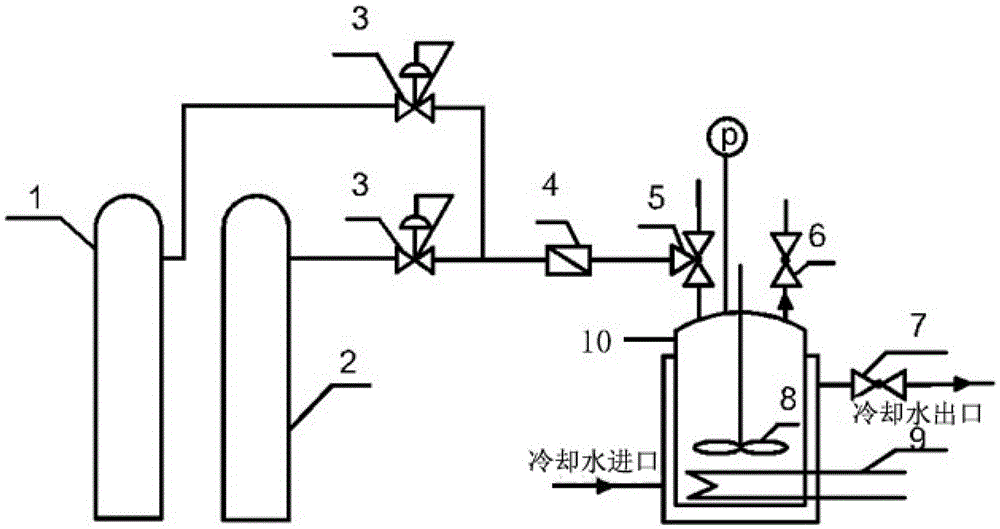

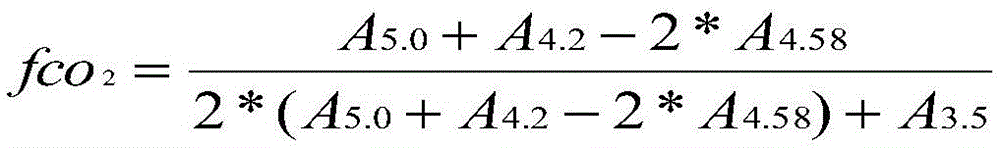

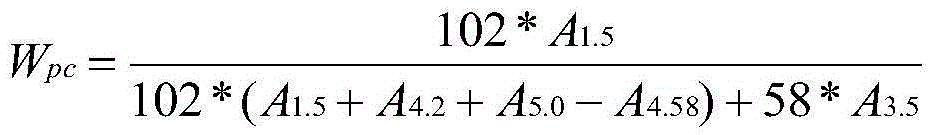

Method used

Image

Examples

Embodiment 1

[0034] Preparation of DMCC-1 Containing Only tert-Butanol Ligand

[0035] (1) Dissolve 1×10-1mol zinc chloride in 100ml deionized water and 20ml tert-butanol mixed solution, stir until zinc chloride is completely dissolved to obtain zinc chloride solution; mix 1×10 -2 mol potassium cobaltcyanide was dissolved in 40ml of deionized water to obtain a potassium cobaltcyanide solution; 15g of PEG4000 was completely dissolved in a mixed solution of 2ml of deionized water and 40ml of tert-butanol at 298K to obtain a PEG solution.

[0036](2) Add 10 g of Mg-AlLDHs to the zinc chloride solution and keep stirring to obtain mixed solution I.

[0037] (3) Under the condition of rapid stirring at 333K, slowly add the potassium cobaltcyanide solution into the mixed solution I dropwise, and control the dropping speed at 5-10 seconds / drop. After the dropwise addition, continue to stir, and quickly add the PEG solution , and kept stirring for 1 h to obtain a mixed solution II.

[0038] (4) T...

Embodiment 2

[0040] The preparation method of the catalyst is basically the same as in Example 1, except that all the parts of tert-butanol used in Example 1 are replaced with ethanol in equal volume, and the prepared catalyst is marked as DMCC-2.

Embodiment 3

[0042] The preparation method of the catalyst is basically the same as in Example 1, except that all the parts of tert-butanol used in Example 1 are replaced with dimethyl ether (DME) in equal volume, and the prepared catalyst is marked as DMCC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com