Preparation method of phthalocyanine green G

A technology of phthalocyanine green and preparation steps, which is applied in the field of preparation of phthalocyanine green G, can solve problems such as low product quality, easy waste of products, easy pollution of the environment, etc., and achieve less impurities, less waste, and less environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

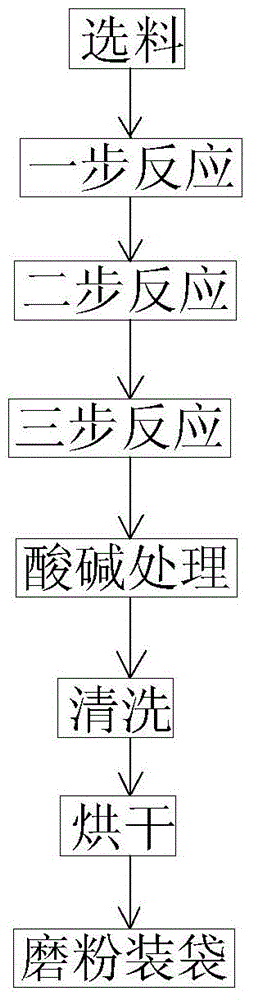

[0020] A kind of preparation method of phthalocyanine green G, its preparation steps are as follows:

[0021] 1) Material selection: select the following raw materials in parts by mass: 18 parts of aluminum trichloride, 2 parts of industrial salt, 4 parts of copper phthalocyanine, 0.3 part of cuprous chloride, 9 parts of chlorine gas, some water;

[0022] 2) One-step reaction: add water into the reaction kettle, then send the selected aluminum chloride into the reaction kettle for reaction, the reaction time is 0.5h, and the reaction temperature is 220°C;

[0023] 3) Two-step reaction: add copper phthalocyanine and cuprous chloride to the material after the one-step reaction for mixed reaction, the reaction time is 7 hours, and the reaction temperature is 180°C;

[0024] 4) Three-step reaction: Introduce chlorine gas into the material after the second-step reaction, and keep the entire environment sealed. The chlorine gas reaction is divided into three stages. The initial stag...

Embodiment 2

[0030] A kind of preparation method of phthalocyanine green G, its preparation steps are as follows:

[0031] 1) Material selection: select the following raw materials in parts by mass: 19 parts of aluminum trichloride, 2.5 parts of industrial salt, 4.5 parts of copper phthalocyanine, 0.35 parts of cuprous chloride, 10 parts of chlorine gas, and some water;

[0032] 2) One-step reaction: add water into the reaction kettle, then send the selected aluminum chloride into the reaction kettle for reaction, the reaction time is 0.75h, and the reaction temperature is 235°C;

[0033] 3) Two-step reaction: add copper phthalocyanine and cuprous chloride to the material after the one-step reaction for a mixed reaction, the reaction time is 7.5 hours, and the reaction temperature is 200°C;

[0034] 4) Three-step reaction: Introduce chlorine gas into the material after the second-step reaction, and keep the entire environment sealed. The chlorine gas reaction is divided into three stages. ...

Embodiment 3

[0040] A kind of preparation method of phthalocyanine green G, its preparation steps are as follows:

[0041] 1) Material selection: select the following raw materials in parts by mass: 20 parts of aluminum trichloride, 3 parts of industrial salt, 5 parts of copper phthalocyanine, 0.4 part of cuprous chloride, 11 parts of chlorine gas, some water;

[0042] 2) One-step reaction: add water into the reaction kettle, then send the selected aluminum chloride into the reaction kettle for reaction, the reaction time is 1h, and the reaction temperature is 250°C;

[0043] 3) Two-step reaction: add copper phthalocyanine and cuprous chloride to the material after the one-step reaction for mixed reaction, the reaction time is 8 hours, and the reaction temperature is 220°C;

[0044] 4) Three-step reaction: Chlorine gas is introduced into the material after the second-step reaction, and the entire environment is kept sealed. The chlorine gas reaction is divided into three stages. The initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com