Quick hot pressing oxidation pretreatment technology for microgranular sulfide type gold ore

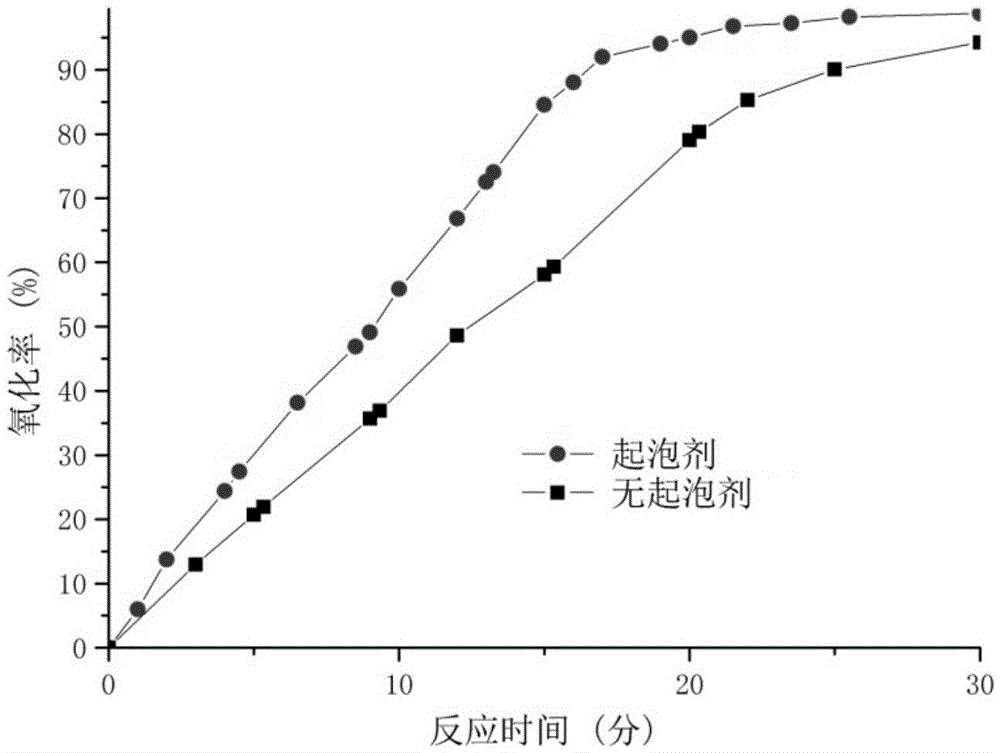

A sulfide-type, hot-pressed oxidation technology, applied in the field of metallurgy, can solve the problems of long production cycle, large changes in gold recovery rate, difficulty in meeting large-scale production, etc., and achieve the effect of reducing residence time and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Use microfine particle dissemination type high-sulfur gold ore, the gold grade of the ore is 2.95 g / t, carbon content 1.5%, sulfur 6.3%, arsenic 0.37%, ore crushed to 70% through -200 mesh, and then respectively adopt Direct traditional cyanidation gold leaching, ordinary thermal oxygen oxidation pretreatment followed by cyanidation gold leaching, and process treatment of the present invention followed by cyanidation gold leaching for gold extraction.

[0022] Direct cyanidation gold leaching: add 200 grams of broken ore samples, add water, adjust pH = 10.5, and make a pulp with a mass concentration of 25%, add sodium cyanide at an amount of 3 g / liter of pulp, and use the existing Conventional roller bottle technology leaching gold, leaching 24 hours, the leaching rate of gold is 1.36%.

[0023] Ordinary thermal oxygen oxidation treatment followed by cyanidation gold leaching: add 210 grams of broken ore samples into water to make a slurry with a mass concent...

Embodiment 2

[0025] Example 2: Use the fine-grained disseminated high-sulfur gold ore, the gold grade of the ore is 2.95 g / t, the carbon content is 1.5%, the sulfur is 6.3%, and the arsenic is 0.37%. The ore is crushed to 70% and passes -200 mesh, and then respectively Direct traditional cyanidation gold leaching, ordinary hot-pressed oxidation pretreatment followed by cyanidation gold leaching, and process treatment of the present invention followed by cyanidation gold leaching for gold extraction.

[0026]Direct cyanidation gold leaching: add 200 grams of broken ore samples, add water, adjust pH = 11, and make a slurry with a mass concentration of 25% of the slurry, add sodium cyanide at an amount of 3 g / liter of slurry, and use the existing Conventional roller bottle technology leaching gold, leaching 24 hours, the leaching rate of gold is 1.36%.

[0027] Ordinary hot-press oxidation pretreatment process: add 210 grams of crushed ore samples into water to make a pulp with a mass concent...

Embodiment 3

[0029] Embodiment 3: use Carlin type gold concentrate, the gold grade of ore is 18 grams / ton, carbon-containing 6.5%, sulfur 26%, arsenic 2.31%, adopt common thermal oxygen oxidation pretreatment then cyanide leaching gold again respectively, And process treatment of the present invention carries out gold extraction again by cyanide immersion gold.

[0030] Ordinary hot-pressed oxidation treatment followed by cyanidation gold leaching: add 500 grams of broken ore samples into water to make a slurry with a mass concentration of 25%, adjust the pH of the slurry to 1.5, add it to the GSH-5 pressure reaction kettle, and pour it into the kettle An oxygen-containing atmosphere was passed inside, the temperature in the kettle was controlled at 220°C, the total pressure was 3.0 MPa (oxygen partial pressure 0.7 MPa), the stirring speed was 500 rpm, and the oxidation treatment was carried out for 3 hours. Filter the oxidized pulp to obtain oxidized slag, and dry the oxidized pulp in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com