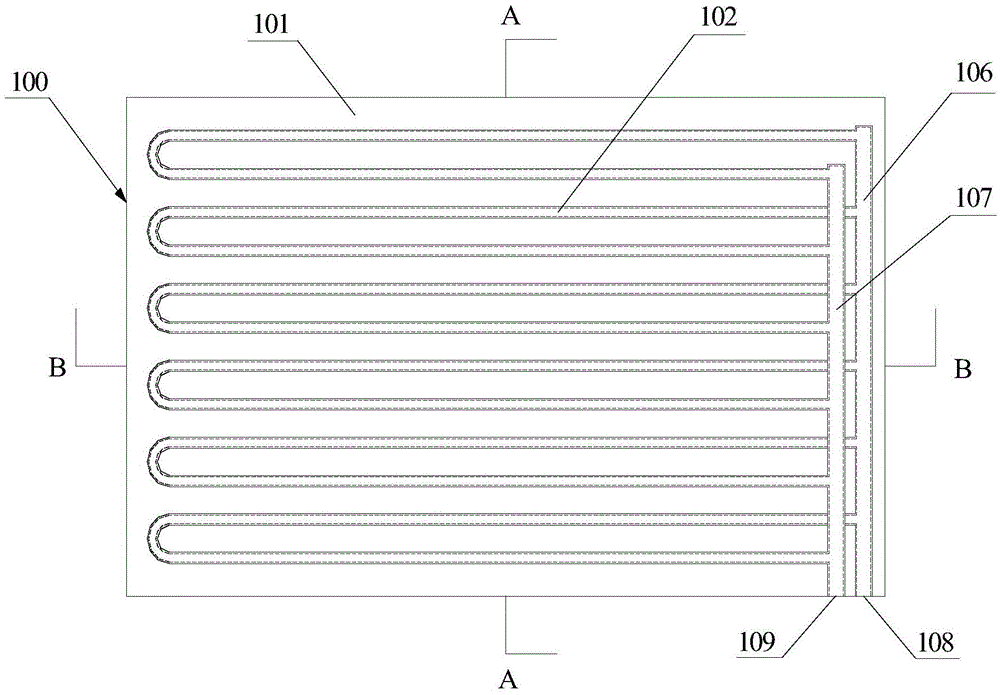

Capillary network radiation heat transfer ceiling floor and ceiling pavement structure thereof

A technology of radiation heat exchange and capillary network, which is applied in heating methods, household heating, building construction, etc., can solve the problems of limiting the cooling and heat exchange capacity of radiant ceiling panels, reducing comfort, shortening service life, etc., to increase direct Contact heat transfer area, reduce heat/cold consumption, increase the effect of heat transfer contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

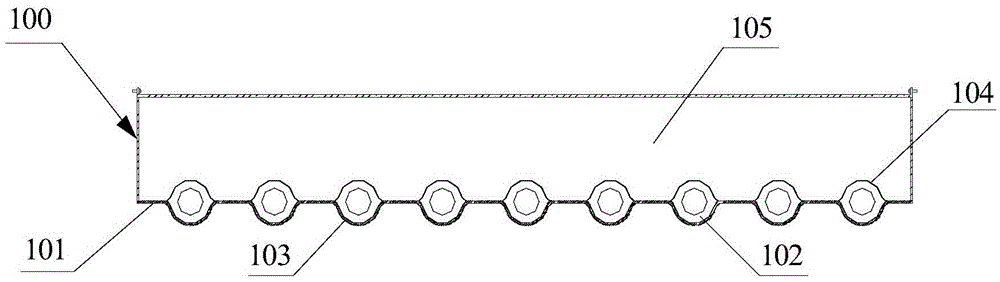

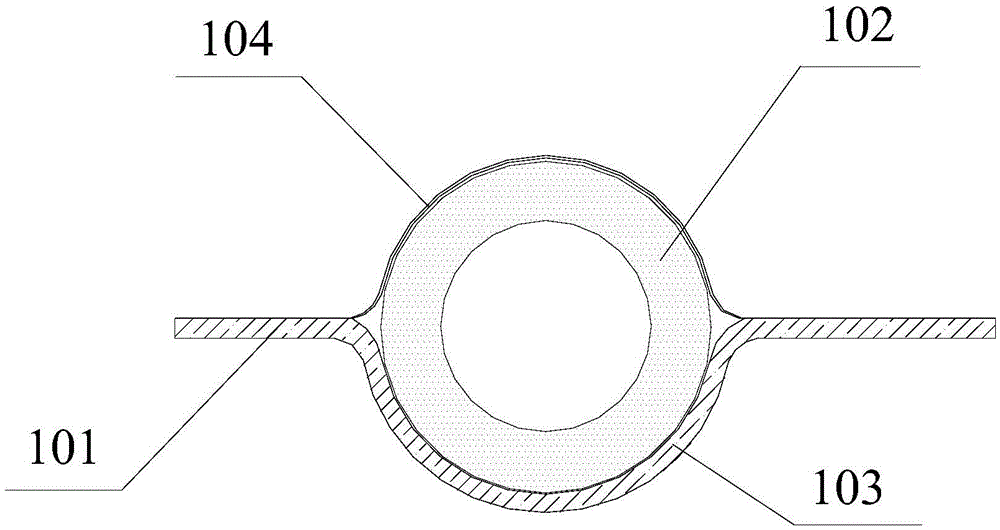

Embodiment Construction

[0036] In the prior art, the heat conduction efficiency between the capillary network and the heat conduction material plate in the radiant ceiling plate is relatively limited, which is an important factor affecting its heat exchange energy efficiency; through technical analysis, it is found that the main reason for the limited heat conduction efficiency is that due to The capillary is usually a pipe with a circular cross-section (because the manufacturing process of the circular-section capillary is relatively mature, and the manufacturing cost is relatively low), while in the radiant ceiling panels of the prior art, the heat-conducting material plate matched with the capillary network is usually It is a flat plate, and the direct contact between the heat-conducting material plate and the capillary is only linear contact, and the contact heat transfer performance is poor. It relies more on the capillary to radiate heat to the surroundings and then transfers the heat to the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com