Reaction chamber and semiconductor processing equipment

A reaction chamber and chamber technology, applied in the field of microelectronics, can solve problems such as shortening the time of cold pump pumping capacity, affecting process results, and increasing the number of cold pump regenerations, so as to prolong the regeneration cycle of cold pumps and improve the process Stability, the effect of guaranteeing process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

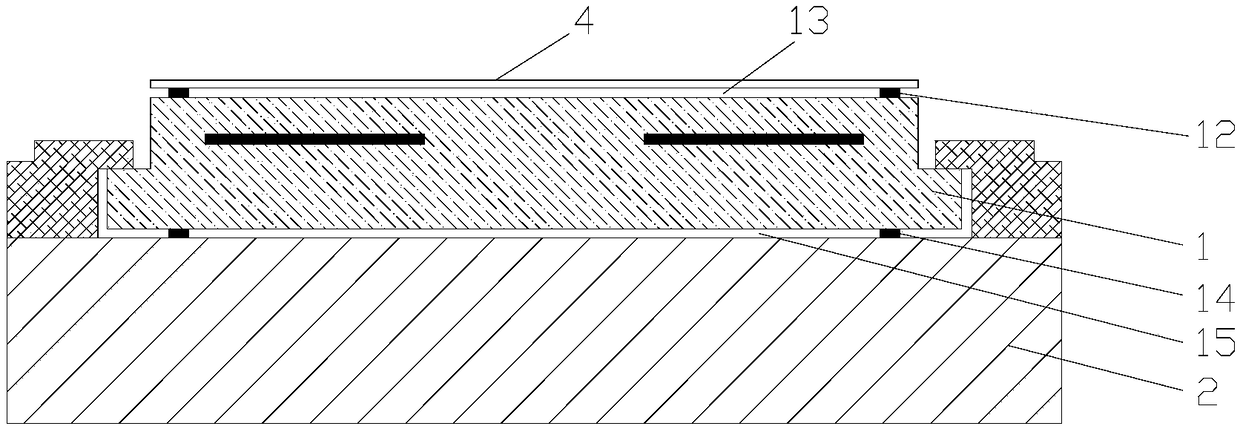

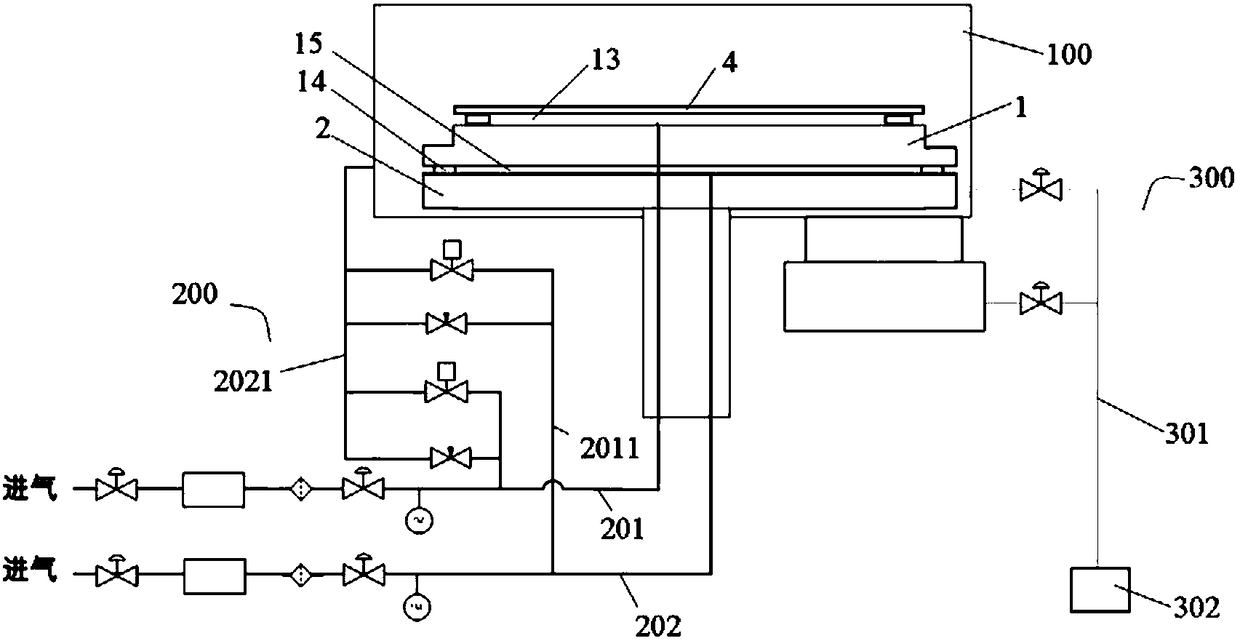

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the reaction chamber and semiconductor processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

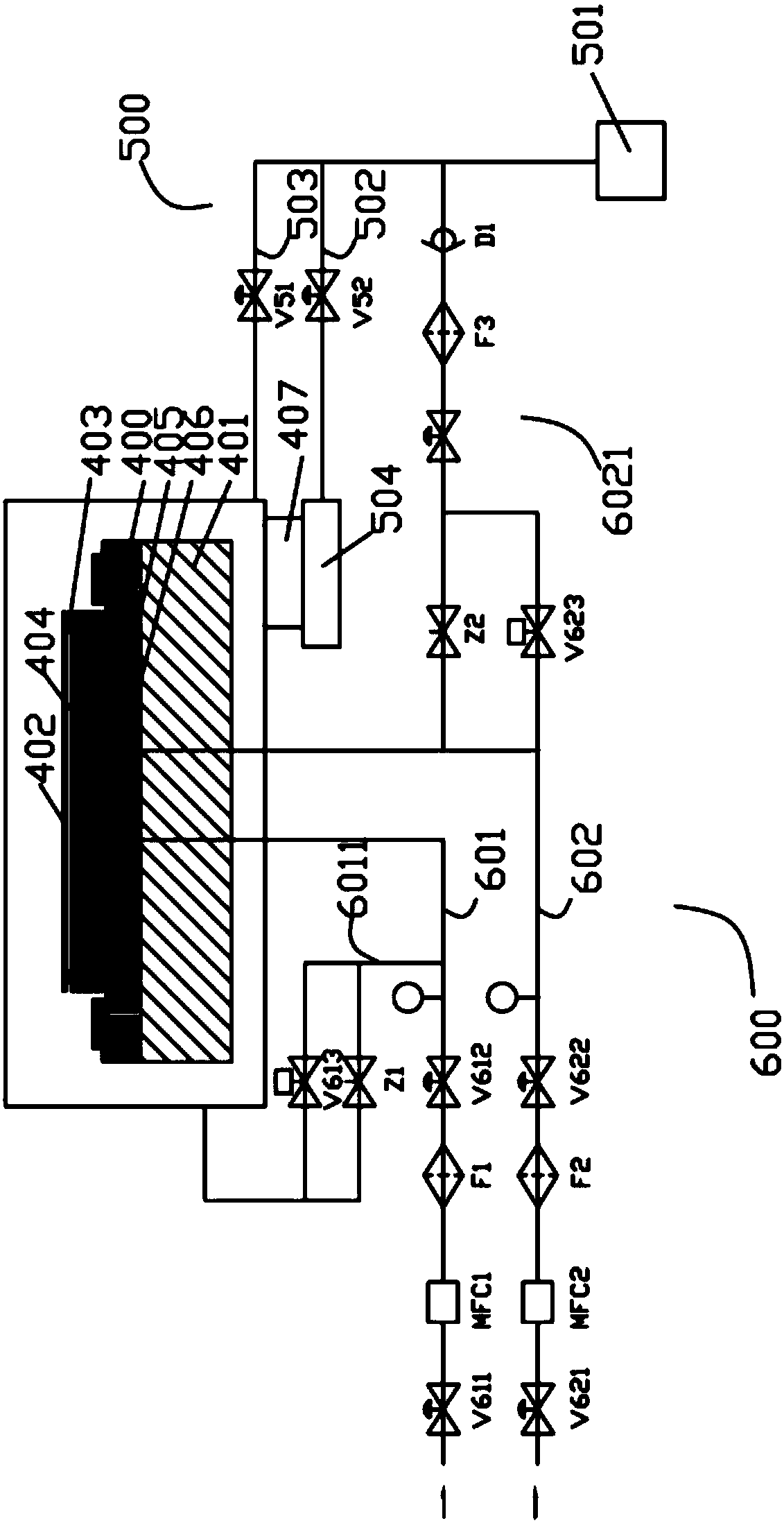

[0024] image 3 A schematic diagram of the gas path of the reaction chamber provided by the embodiment of the present invention. see image 3 , The reaction chamber provided by the embodiment of the present invention includes a chamber pumping system 500 , a wafer holding device and a back blowing gas supply system 600 . Wherein, the chamber pumping system 500 is used to evacuate the reaction chamber, which includes a system dry pump 501, and a first branch 502 and a second branch 503 connected in parallel, and the system dry pump 501 passes through the first branch. The path 503 and the second branch path 502 are connected to the reaction chamber, and are used for initial pumping of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com