Preparation technology of natural fish protein powder by biological fermentation

A technology of fish protein powder and bio-fermentation, which is applied in animal protein processing, protein food processing, fish protein components, etc. It can solve the problems of weak finishing of aquatic products, difficult storage of fresh goods, and small profit space, so as to improve comprehensive utilization Efficiency, ease of absorption, and flavor-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

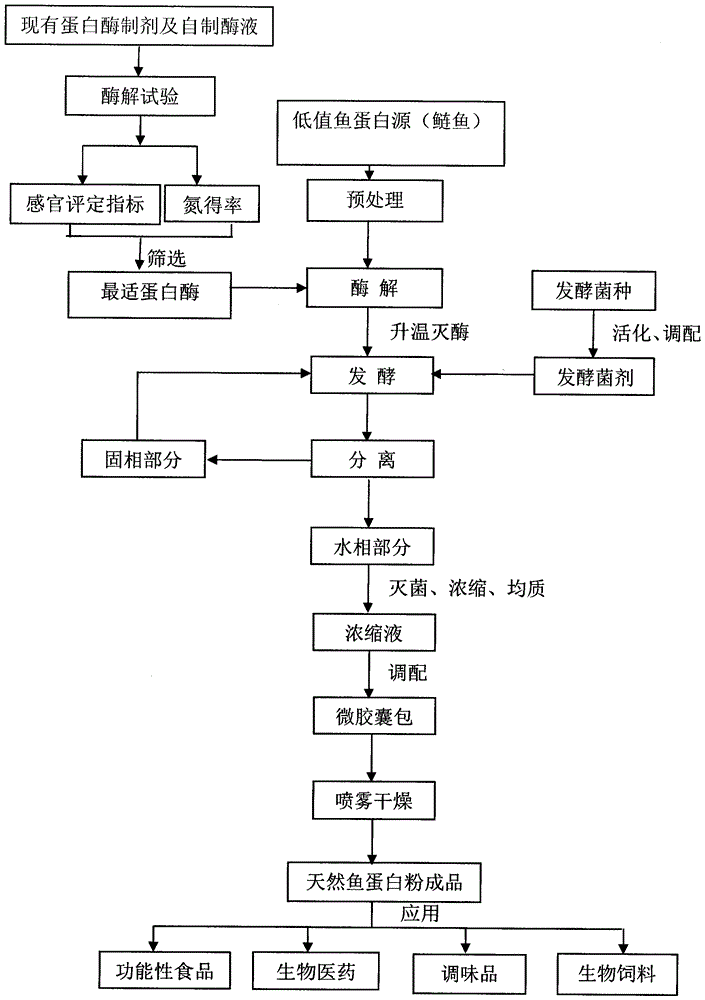

Method used

Image

Examples

Embodiment 1

[0028] A production process for preparing natural fish protein powder by biological fermentation, comprising the steps of:

[0029] (1) Raw material pretreatment: take fresh or frozen silver carp to clean, remove impurities, chop and mix, mix with appropriate amount of water after chopping and mix, and mix with water according to the weight ratio of 1:5-15, and carry out after mixing. Beat the pulp and put it into the colloid mill to refine it, so that the fish skin, fish bones and fish meat are evenly dispersed, and then adjust the amount of water appropriately to make the solid content in it ≤ 25%. At this time, the stock solution is prepared;

[0030] (2) Enzymolysis: Sterilize the stock solution prepared in step (1) at 100°C, cool to 40-50°C after sterilization, and then add compound protease for enzymolysis. The enzymolysis time is 4-8h, and the order of adding the compound protease is to add compound enzyme A (neutral protease: papain = 1: 1), then add compound enzyme B ...

Embodiment 2

[0036] A production process for preparing natural fish protein powder by biological fermentation, comprising the following steps:

[0037] (1) Raw material pretreatment: clean, remove impurities, chop and mix the raw materials, mix them with an appropriate amount of water, mix them with water at a weight ratio of 1:5, beat them after mixing, and put them into the colloid mill Medium refinement, so that the fish skin, fish bones, and fish meat are evenly dispersed, and the stock solution is prepared;

[0038](2) Enzymolysis: Sterilize the stock solution prepared in step (1) at 100°C for 10 minutes, cool to 40-50°C after sterilization, then add compound protease A, after enzymolysis for 2 hours, add compound Protease B, continue to enzymatically hydrolyze for 2 hours, wherein the addition of compound protease A and compound protease B is added according to 2% of the stock solution, and the enzymolysis solution is obtained after the enzymolysis is completed;

[0039] (3) Ferment...

Embodiment 3

[0044] A production process for preparing natural fish protein powder by biological fermentation, comprising the following steps:

[0045] (1) Raw material pretreatment: clean, remove impurities, chop and mix the raw materials, mix them with an appropriate amount of water, and mix them with water at a weight ratio of 1:10, beat them after mixing, and put them into the colloid mill Medium refinement, so that the fish skin, fish bones, and fish meat are evenly dispersed, and the stock solution is prepared;

[0046] (2) Enzymolysis: Sterilize the stock solution prepared in step (1) at 100°C for 10 minutes, cool to 40-50°C after sterilization, then add compound protease A, after enzymatic hydrolysis for 3 hours, add compound Protease B, continue to enzymatically hydrolyze for 3 hours, wherein the addition of compound protease A and compound protease B is added according to 1% of the stock solution, and the enzymatic hydrolysis solution is obtained after the enzymolysis is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com