Sulfonated silk fibroin film modified polytetrafluoroethylene artificial blood vessel and method for preparing same

A technology of polytetrafluoroethylene and sulfonated silk fibroin, which is applied in pharmaceutical formulations, coatings, drug delivery, etc., can solve problems such as fibroin film chapping and affecting the performance of artificial blood vessels, achieve good anastomosis, meet clinical application, The effect of low hemolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

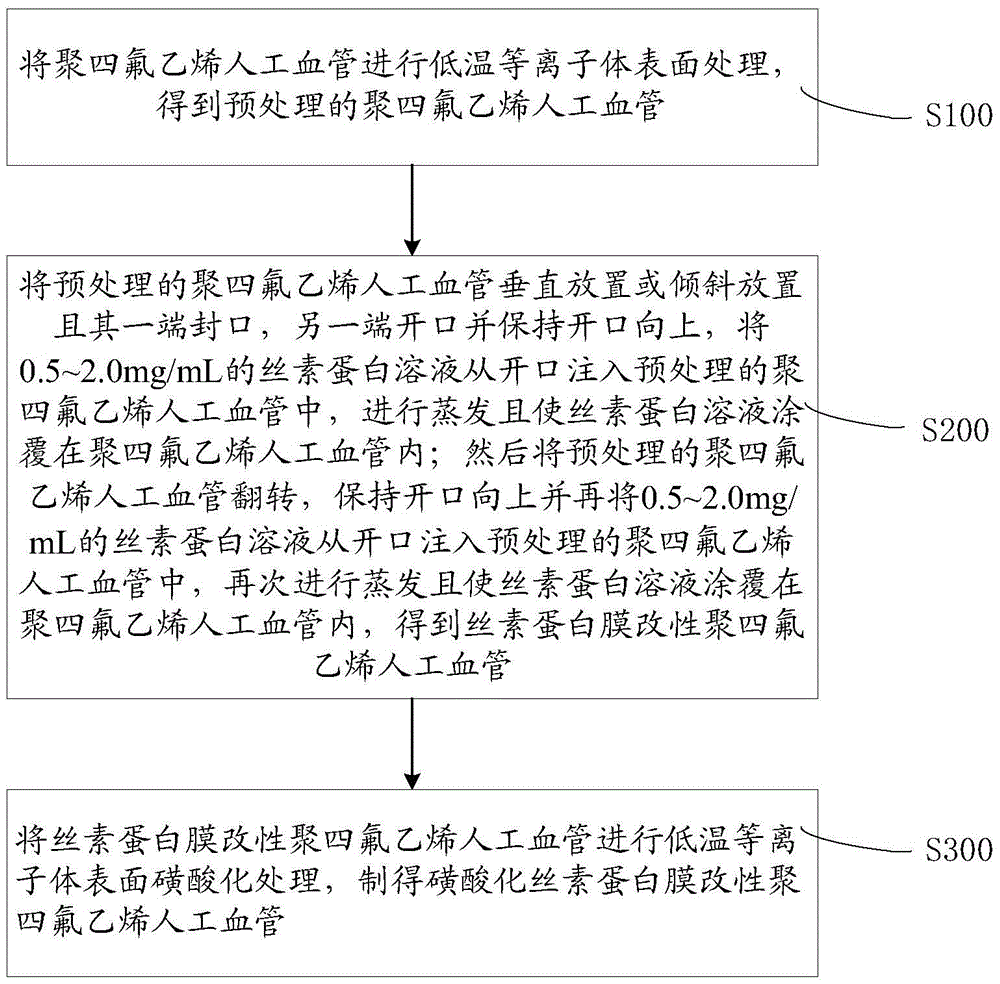

[0033] see figure 1 , a method for preparing a sulfonated silk fibroin membrane-modified polytetrafluoroethylene artificial blood vessel according to one embodiment, comprising the following steps.

[0034] Step S100: subjecting the polytetrafluoroethylene (PTFE) artificial blood vessel to low-temperature plasma surface treatment to obtain a pretreated polytetrafluoroethylene artificial blood vessel.

[0035] Since PTFE is an inert polymer with low surface energy, if silk fibroin is directly coated on the surface of PTFE, the adhesion stability is poor. Low-temperature plasma surface treatment of PTFE artificial blood vessels can increase the surface free energy of PTFE, make silk fibroin easy to adhere to the surface of PTFE, and improve the stability of adhesion of silk fibroin on the surface of PTFE.

[0036] In one embodiment, the processing gas for the low-temperature plasma surface treatment is argon, and the discharge power is 40-80W. A large number of experimental st...

Embodiment 1

[0057] (1) The ePTFE artificial blood vessel with an inner diameter of 4mm is subjected to low-temperature plasma surface treatment to obtain a pretreated polytetrafluoroethylene artificial blood vessel; the treatment gas for low-temperature plasma surface treatment is argon, the fixed discharge voltage pressure is 70Pa, and the discharge power It is 80W, and the discharge time is 10min. The pretreated polytetrafluoroethylene artificial blood vessel was placed in the air for 10 minutes.

[0058] (2) prepare silk fibroin solution: the molar concentration of silk is 0.5% Na 2 CO 3 Boil in the solution for 120min, wash and dry with water, add CaCl with a molar ratio of 1:8:2 2 、H 2 A ternary solvent of O and ethanol was dissolved in a water bath at 80°C for 24 hours, then dialyzed in distilled water and deionized water for 3 days, and suction filtered to obtain a silk fibroin solution.

[0059] (3) Place the pretreated polytetrafluoroethylene artificial blood vessel verticall...

Embodiment 2

[0062] The difference between embodiment 2 and embodiment 1 is:

[0063] The inner diameter of the ePTFE artificial blood vessel in Example 2 is 6mm.

[0064] The discharge power of the low-temperature plasma surface treatment in step (1) is 60W.

[0065] The concentration of the silk fibroin solution in step (3) is 1.6 mg / mL.

[0066] The discharge power of the low-temperature plasma surface sulfonation treatment in step (4) is 90W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com