Haloamine modified xanthan gum/chitosan composite antibacterial dressing and preparation method thereof

A technology of compounding antibacterial and xanthan gum, applied in the medical field, can solve the problems of easy dissolution of antibacterial agents and low antibacterial efficiency, and achieve the effect of good antibacterial performance and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

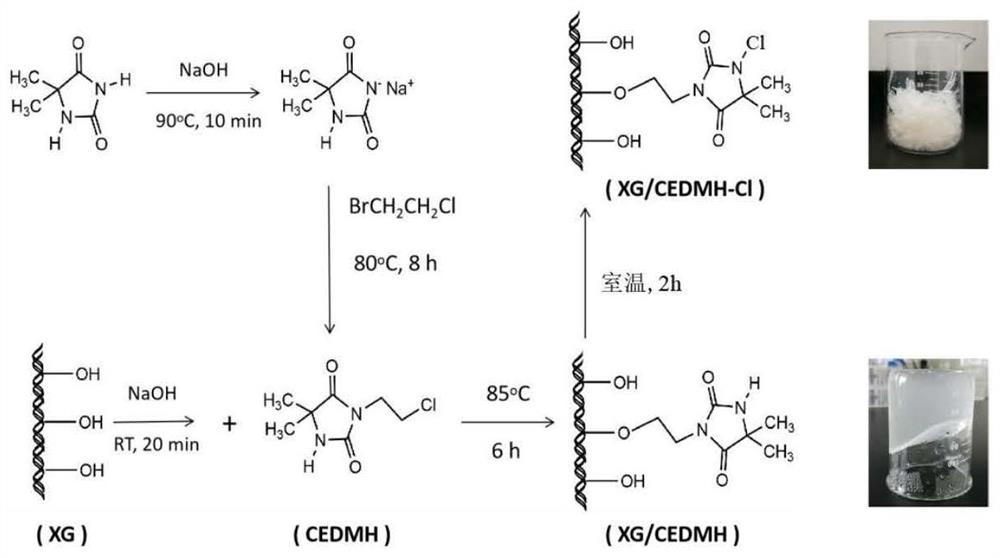

[0087] A method for preparing haloamine modified xanthan gum antibacterial agent, comprising the steps:

[0088] (1) Weigh 3.99g NaOH (0.1mol) into a round bottom flask containing 100mL ethanol solution, add 12.81g 5,5-dimethylhydantoin (DMH, 0.1mol), reflux at 90°C for 10min; Adjust the temperature to 85°C, add 14.34g of 1-bromo-2-chloroethane (BCE, 0.1mol,) and continue to condense and reflux the reaction for 8h. White particles (sodium salt) can be seen in the solution. After removing ethanol by rotary evaporation at 80°C, Then wash with ethyl acetate / water (4 / 1, v / v), transfer the mixed solution to a separatory funnel, let it stand for 10 minutes to separate, keep the upper layer solution, and remove ethyl acetate by rotary evaporation at 60°C . The obtained product was poured into a beaker while it was hot (it can be observed that the solubility of the product decreases as the temperature decreases). The product 3-(2'-chloroethyl)-5,5-dimethylhydantoin (CEDMH) was a whi...

Embodiment 2

[0094] Embodiment 2 XG and CEDMH molar ratio optimization

[0095] Adjust the molar ratio of XG and CEDMH in Example 1 to 1:1, 1:2, 1:3, 1:4, 1:6, and keep the others consistent with Example 1 to obtain XG / CEDMH-Cl.

[0096] The obtained XG / CEDMH-Cl was subjected to a performance test, and the test results are shown in Table 1:

[0097] It can be seen from Table 1 that when the molar ratio of XG and CEDMH is 1:1, the chlorine content of the product XG / CEDMH-Cl is low, about 0.06%. Increasing the amount of CEDMH can gradually increase its grafting rate to XG, which is reflected in the gradual increase of the chlorine content of XG / CEDMH-Cl, but when the molar ratio of XG to CEDMH exceeds 1:5, the chlorine content does not increase much. Therefore, a scheme of 1:5 molar ratio of XG to CEDMH was chosen to prepare XG / CEDMH-Cl.

[0098] The test result of table 1 embodiment 1 and 2

[0099]

Embodiment 3

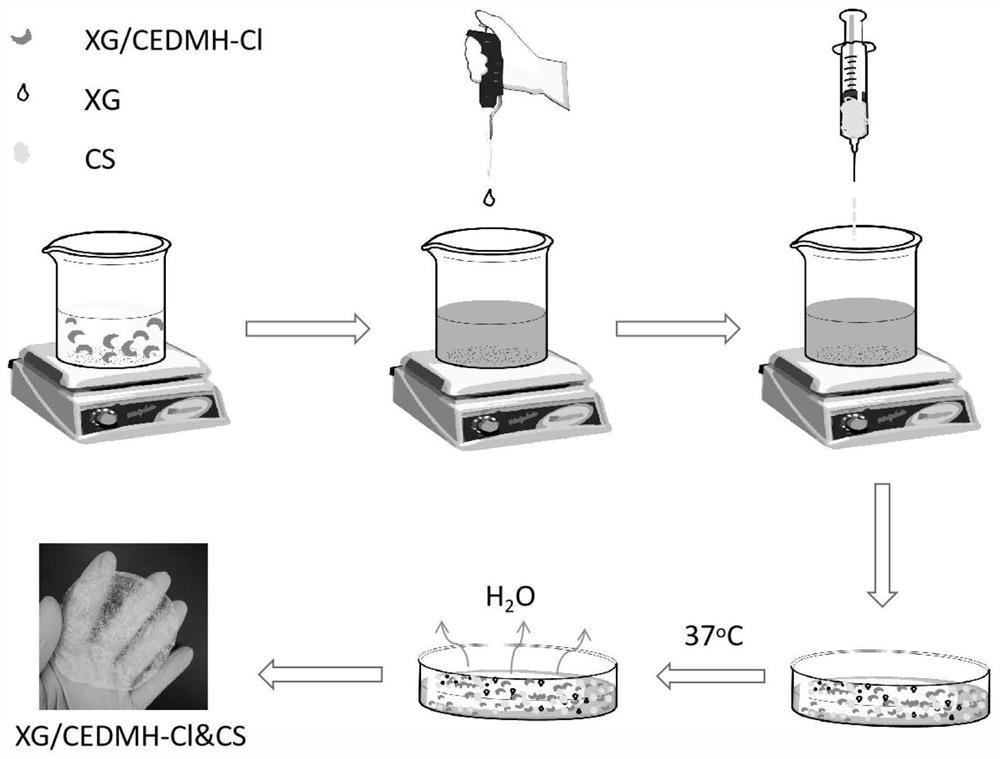

[0101] A method for preparing haloamine modified xanthan gum / chitosan composite antibacterial dressing, the process is as follows image 3 , including the following steps:

[0102] Add 0.15 g of XG / CEDMH-Cl obtained in Example 1 into 30 mL of water to dissolve; then add 2 mL of glycerin and continue stirring; 3 COOH aqueous solution is used as the solvent to prepare chitosan (CS) solution with a concentration of 0.5% (0.03g chitosan prepares 6mL chitosan solution); use a syringe with a blue needle (type 22G) to inject 6mL CS solution into the XG with high-speed stirring / CEDMH-Cl solution, mix evenly, then pour the mixture into a petri dish, and dry at 37°C to obtain a haloamine-modified xanthan gum / chitosan composite antibacterial dressing (XG / CEDMH-Cl&CS dressing film).

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com