Compound synergistic additive for wet-process flue gas desulphurization and preparation method of compound synergistic additive for wet-process flue gas desulphurization

A technology of wet flue gas desulfurization and compound efficiency, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of no reliable additive selection and evaluation scheme, large application randomness, etc., and achieve low cost and high efficiency Desulfurization efficiency, the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The wet flue gas desulfurization composite synergistic additive designed by the present invention, wherein the weight and number ratio of each component is: 65 parts of adipic acid; 7 parts of nylon acid; 7 parts of sodium citrate; 4 parts of sodium sulfate; 6 parts of iron sulfate 11 parts of manganese chloride; under normal temperature and pressure, take adipic acid, nylon acid, sodium citrate, sodium sulfate, ferric sulfate, manganese chloride and mix and stir respectively Can.

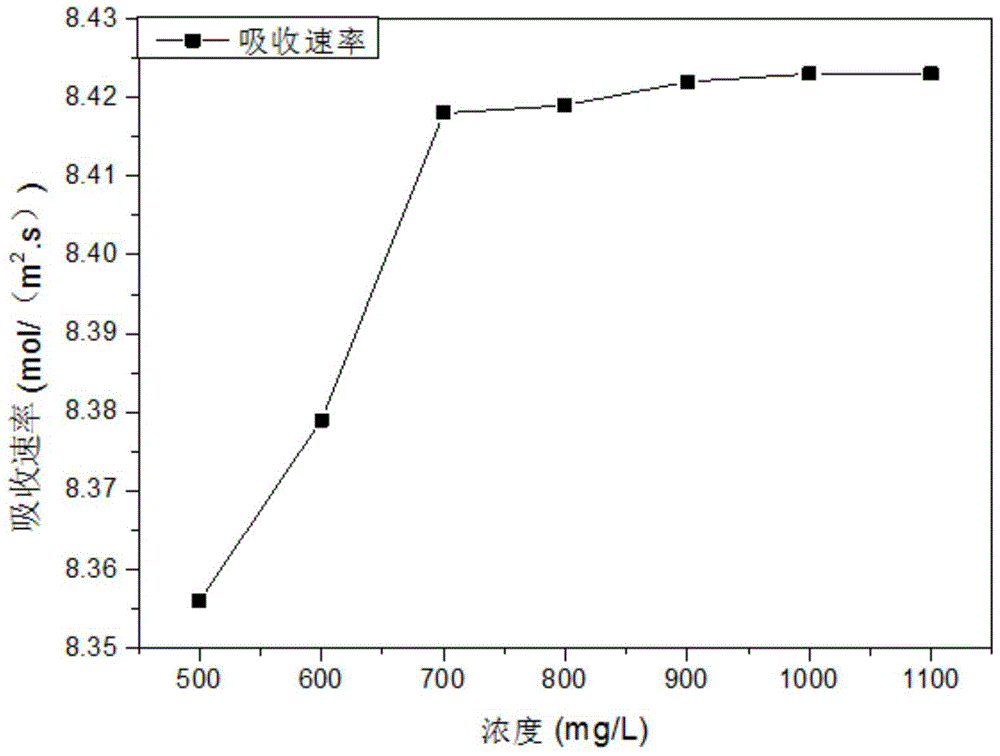

[0020] The above raw materials are mixed and stirred according to the weight ratio of each component and the finished product is added into the desulfurization absorption tower. The initial addition amount is 750mg / L, and the daily addition amount is supplemented according to the calculation of synergist loss.

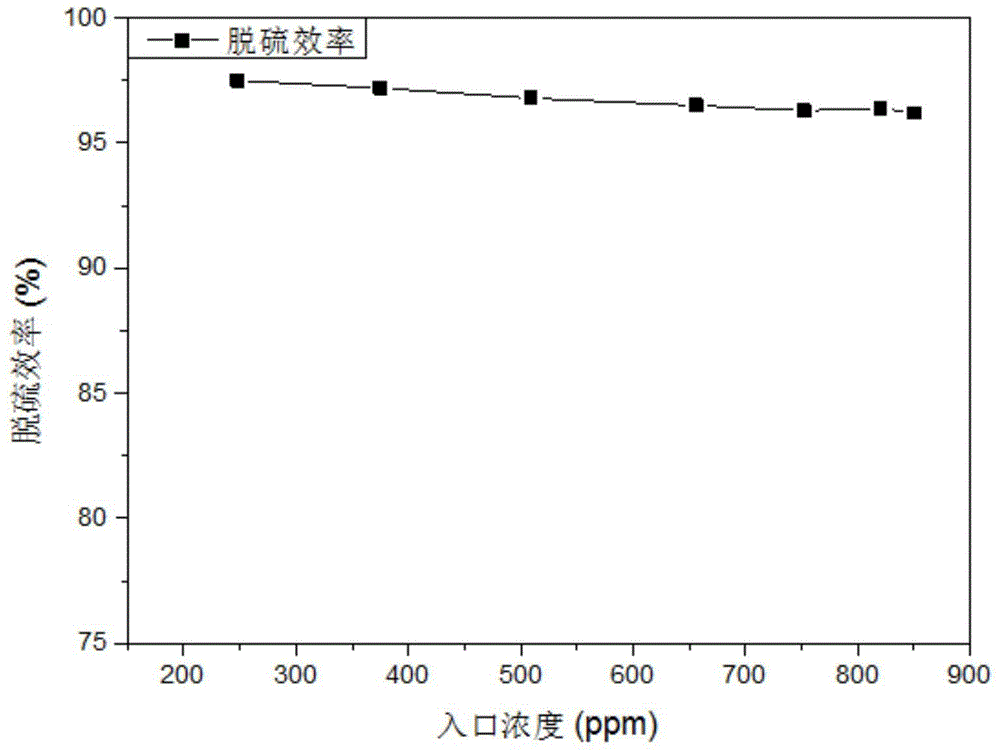

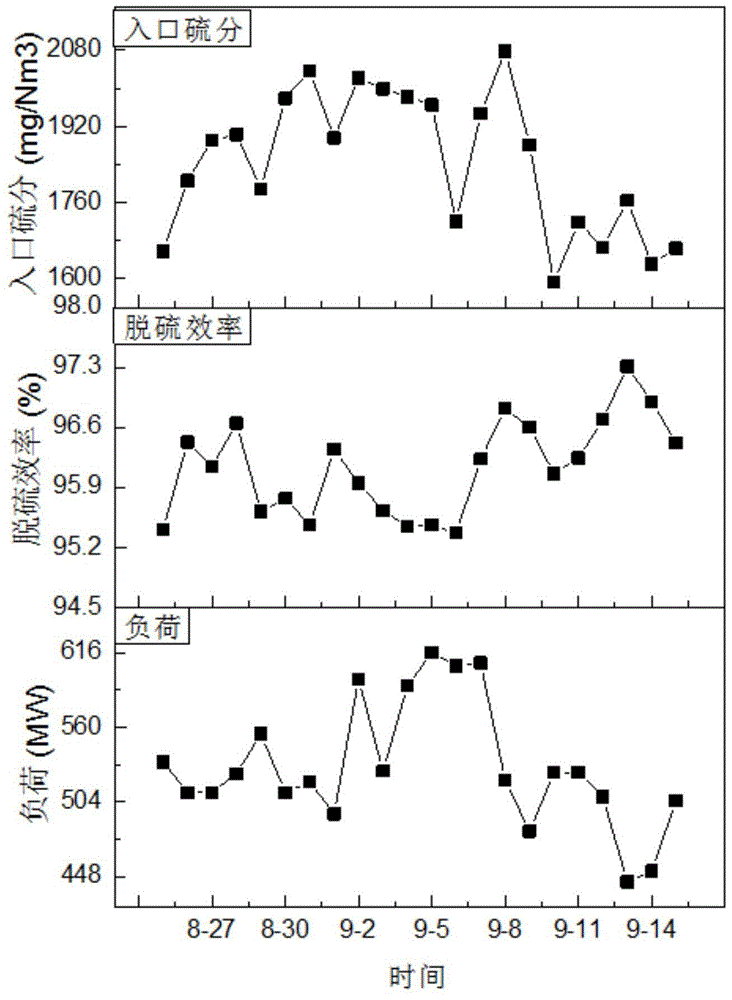

[0021] The composite desulfurization synergistic additive provided in this example was applied to a wet flue gas desulfurization system for a 600MW power plant boiler. The long-term ...

Embodiment 2

[0023] In this embodiment, the designed wet flue gas desulfurization compound synergistic additive, wherein the weight and number ratio of each component is:

[0024] 70 parts of adipic acid; 10 parts of nylon acid; 7 parts of sodium citrate; 3 parts of sodium sulfate; 5 parts of iron sulfate; 5 parts of manganese chloride; Take adipic acid, nylon acid, sodium citrate, sodium sulfate, ferric sulfate and manganese chloride, mix and stir evenly.

[0025] The finished product after mixing and stirring the above raw materials according to the ratio of parts by weight is added to the desulfurization absorption tower. The initial addition amount is 800mg / L, and the daily addition amount is supplemented according to the calculation of synergist loss.

[0026] The composite desulfurization synergistic additive provided in this example was applied to a wet flue gas desulfurization system for a 600MW power plant boiler. The long-term monitoring results showed that the desulfurization ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com