Full-automatic lime liquid preparing system and method for deep treatment of dyeing wastewater

A technology for advanced treatment, printing and dyeing sewage, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

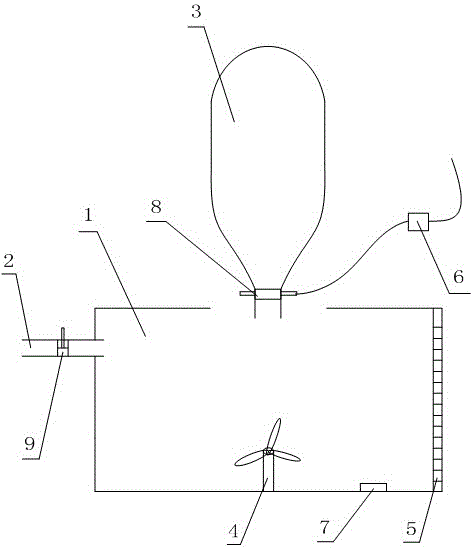

[0027] Such as figure 1 The shown fully automatic lime dosing system for the advanced treatment of printing and dyeing sewage includes a dosing tank 1, a water inlet pipe 2, a water inlet valve 9, and a bulk material tank 3 arranged above the dosing tank 1, and also includes a liquid level Sensor 5: used to collect the liquid level height signal of the liquid distribution tank 1, and transmit the signal to the control module; the control module: used to receive the liquid level height signal collected by the liquid level sensor 5, and according to the The signal controls the action of the water inlet valve 9 and the discharge valve 8 of the bulk material tank 3 . The bulk material tank 3 is a constant pressure ash tank with an air compressor; a stirring device 4 is also arranged inside the liquid distribution tank 1; a time relay 6 is connected between the control module and the discharge valve 3 The water inlet valve 9 and the discharge valve 8 are all self-control valves; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com