Horizontal gradually-pressurizing direct-current electric field sludge drying device

A direct current electric field and sludge drying technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of not configuring filter belts, and achieve reliable constraints, running smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be further explained based on the drawings and the embodiments.

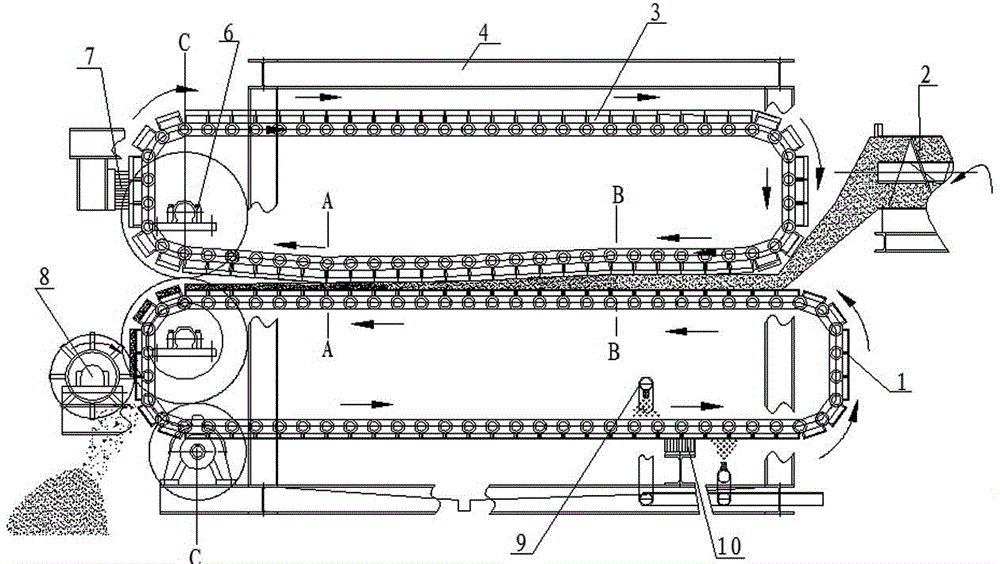

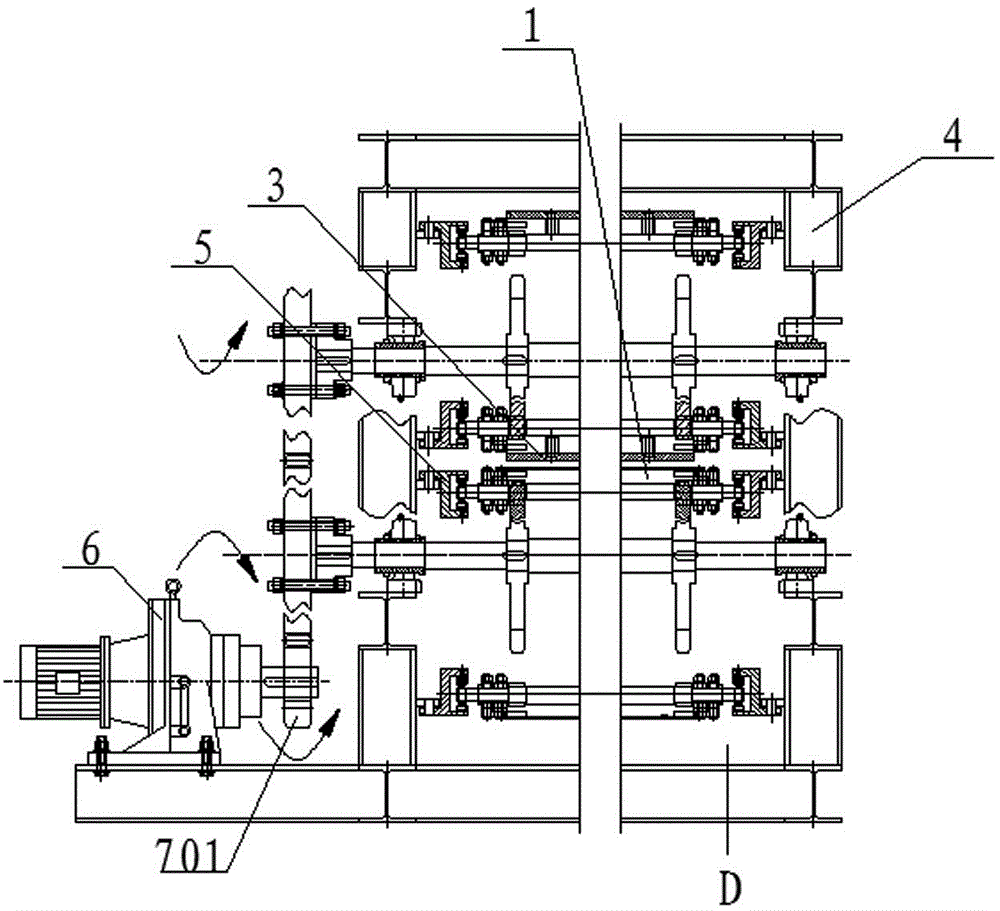

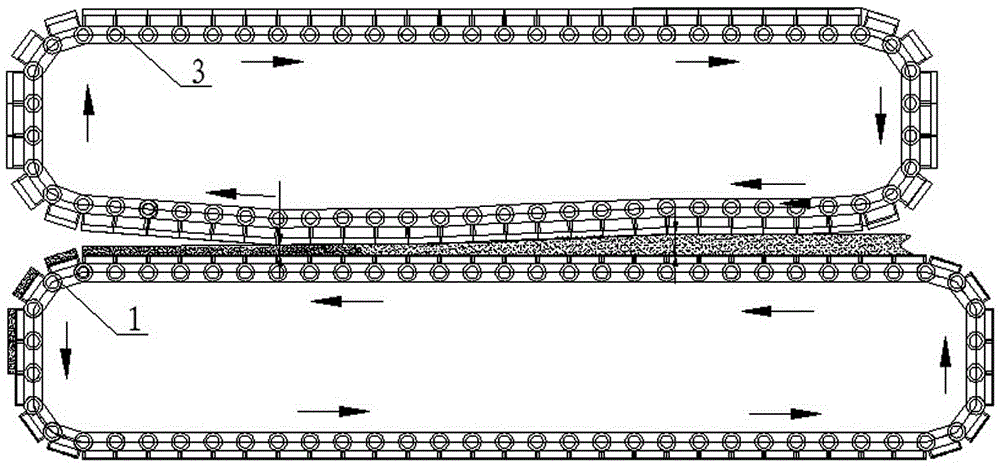

[0023] figure 1 The horizontal gradually pressurized DC electric field sludge drying device shown is supporting a daily processing capacity of 20,000 m 3 An embodiment of a municipal sewage treatment plant for sludge dewatering. The structural feature of the device is embodied in the use of built-in guide rails 5 to limit the upper crawler 3 and the lower crawler 1 to cyclically drive in a determined track. Because the distance between the upper and lower rails 5 is in a transverse wedge shape, a progressive pressurization structure of the upper crawler 3 relative to the lower crawler 1 is formed. Under the condition of DC electric field, this structure continuously and orderly increases the pressing force as the moisture content of the wet sludge being pressed decreases. On the other hand, the electron flow hits the water wall of the cell water in the wet sludge,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com