Recover method for acid mist generated by acid hydrolysis reaction in citric acid production

A recovery method, citric acid technology, applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation, etc., can solve the problems of product yield reduction, citric acid mist loss, atmospheric environment pollution, etc., to improve The effect on product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

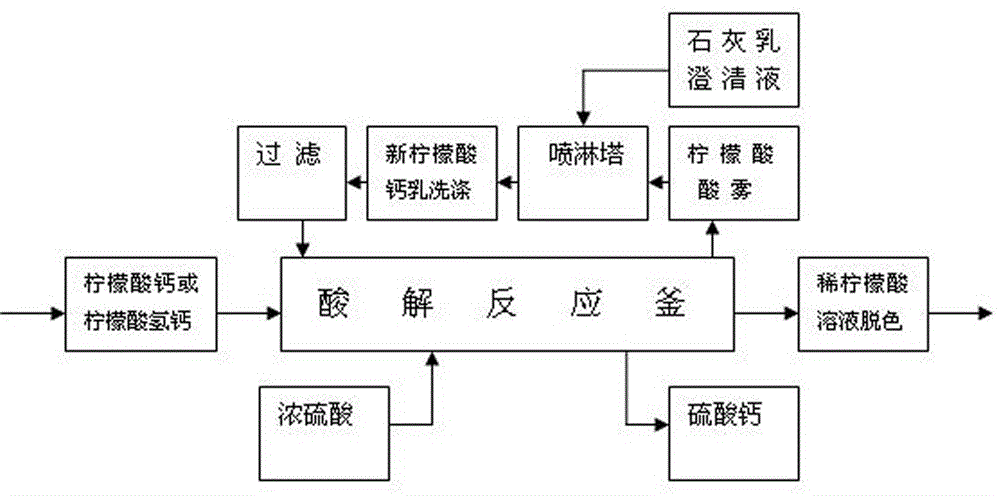

[0016] see figure 1 As shown, the present invention provides a method for recovering acid mist produced by acidolysis reaction in the production of citric acid, including the acidolysis reaction still in the existing production process and the acidolysis reaction in the still, and also includes the following steps:

[0017] (1) Collect the clarified supernatant of milk of lime as the circulating fluid of the spray tower;

[0018] (2) Pump the above circulating liquid into the spray tower, and form the circulating liquid to circulate and spray in the tower;

[0019] (3) The acid mist outlet of the acidolysis reaction kettle is connected with the air inlet of the spray tower through the pipeline, and the citric acid mist generated in the acidolysis reaction kettle is introduced into the spray tower through the pipeline, and is sprayed and absorbed by the circulating liquid , to generate calcium citrate and water, and the tail gas is discharged through the outlet of the spray to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com