Polyethylene glycol terephthalate composite material and preparation method thereof

A technology of polyethylene terephthalate and composite materials, which is applied in the chemical industry, can solve other problems such as general performance, and achieve the effects of good toughness and strength, good environmental benefits, and environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Pour the dried 2 parts of titanium dioxide and 13 parts of aluminum silicate powder into a high mixer with a setting temperature of 100-120°C and a stirring speed of 3000rpm, and then add 1 part of lanthanum phytate and 1 part of lanthanum stearate and 0.1 part of silane coupling agent, the rotating speed was adjusted to 5000 rpm and stirred for 30 minutes. The above mixture was mixed with 10 parts of EPDM rubber to prepare an elastomer coated composite material. Then, the above elastomer-coated composite material and 100 parts of polyethylene terephthalate were melt-blended on a twin-screw extruder to prepare a polyethylene terephthalate composite material. The temperature of each section of the extruder is 180-240° C., and the screw speed is 100-300 rpm. After granulation and drying, prepare national standard mechanical performance test specimens on the injection molding machine. The temperature of each section of the injection molding machine is 250-260°C, the injec...

Embodiment 2、3

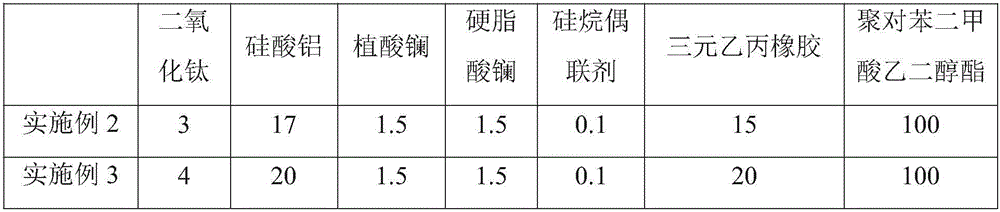

[0018] Examples 2 and 3 The conditions, process, and raw materials for preparing polyethylene terephthalate composite materials are the same as in Example 1, and tested, but the weight parts of raw materials are different, as shown in Table 1. The mechanical properties of the obtained splines are listed in Table 3.

[0019] Table 1

[0020]

Embodiment 4

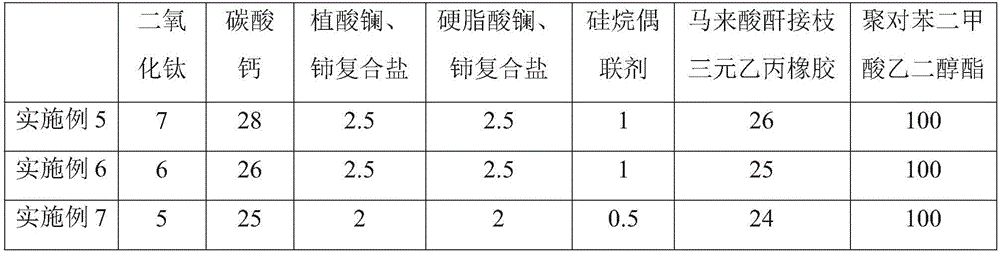

[0022] Pour the dried 8 parts of titanium dioxide and 30 parts of calcium carbonate powder into a high mixer with a setting temperature of 100-120 °C and a stirring speed of 3000 rpm, and then add 3 parts of lanthanum phytate and cerium compound salt, 3 parts of hard Lanthanum fatty acid, cerium complex salt and 1 part of silane coupling agent, the rotation speed was adjusted to 5000 rpm and stirred for 30 minutes. The above mixture was grafted with 28 parts of maleic anhydride to EPDM rubber to prepare elastomer-coated composites. Then, the above elastomer-coated composite material and 100 parts of polyethylene terephthalate were melt-blended on a twin-screw extruder to prepare a polyethylene terephthalate composite material. The temperature of each section of the extruder is 180-240° C., and the screw speed is 100-300 rpm. After granulation and drying, prepare national standard mechanical performance test specimens on the injection molding machine. The temperature of each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com