A kind of lubricating oil and preparation method thereof

A technology of lubricating oil and weight percentage, which is applied in the field of lubricating oil and its preparation, can solve the problems of adverse effects on engine life, high dependence on natural resources, and large movement resistance, so as to achieve good economic benefits and environmental friendliness, and reduce dependence degree, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

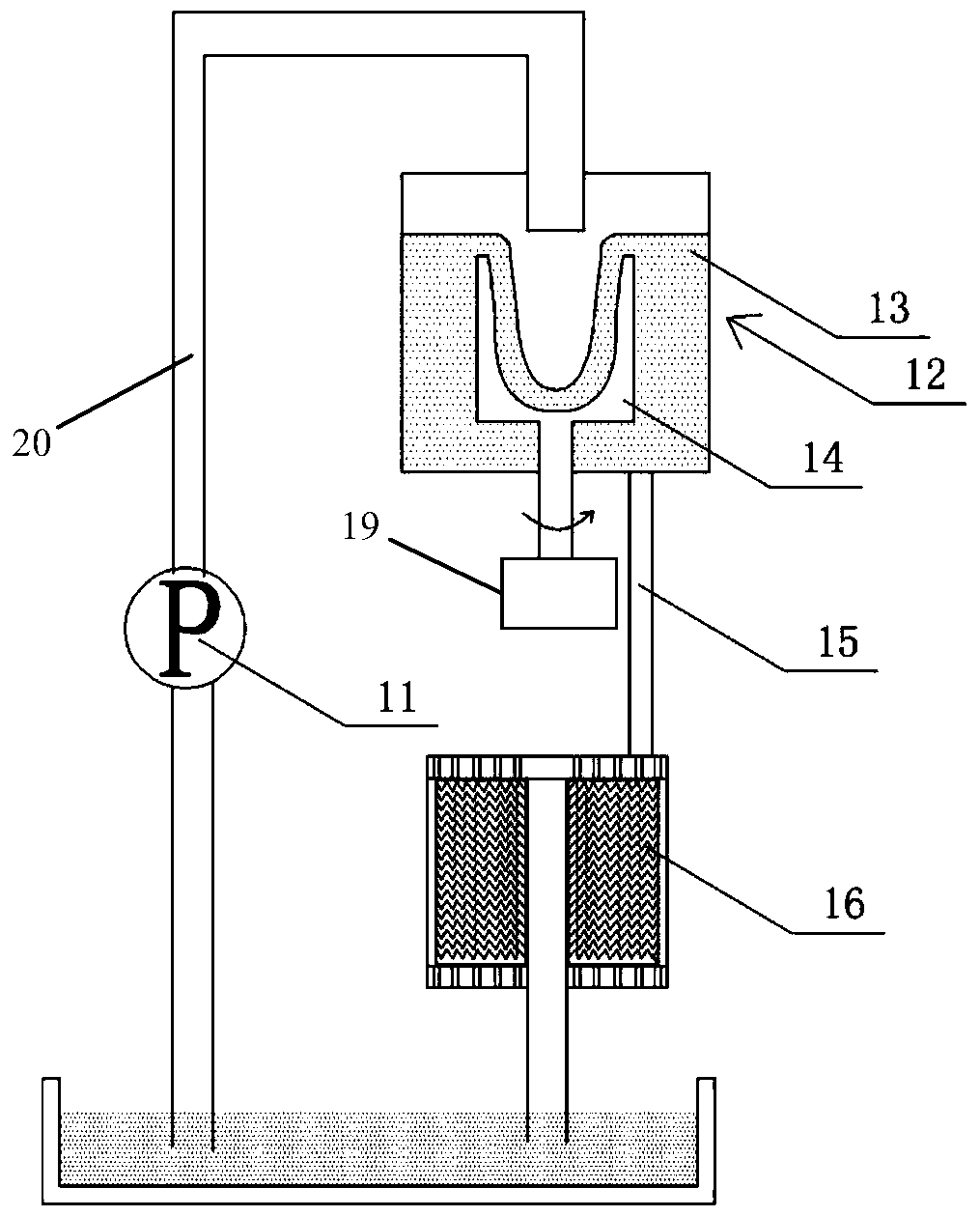

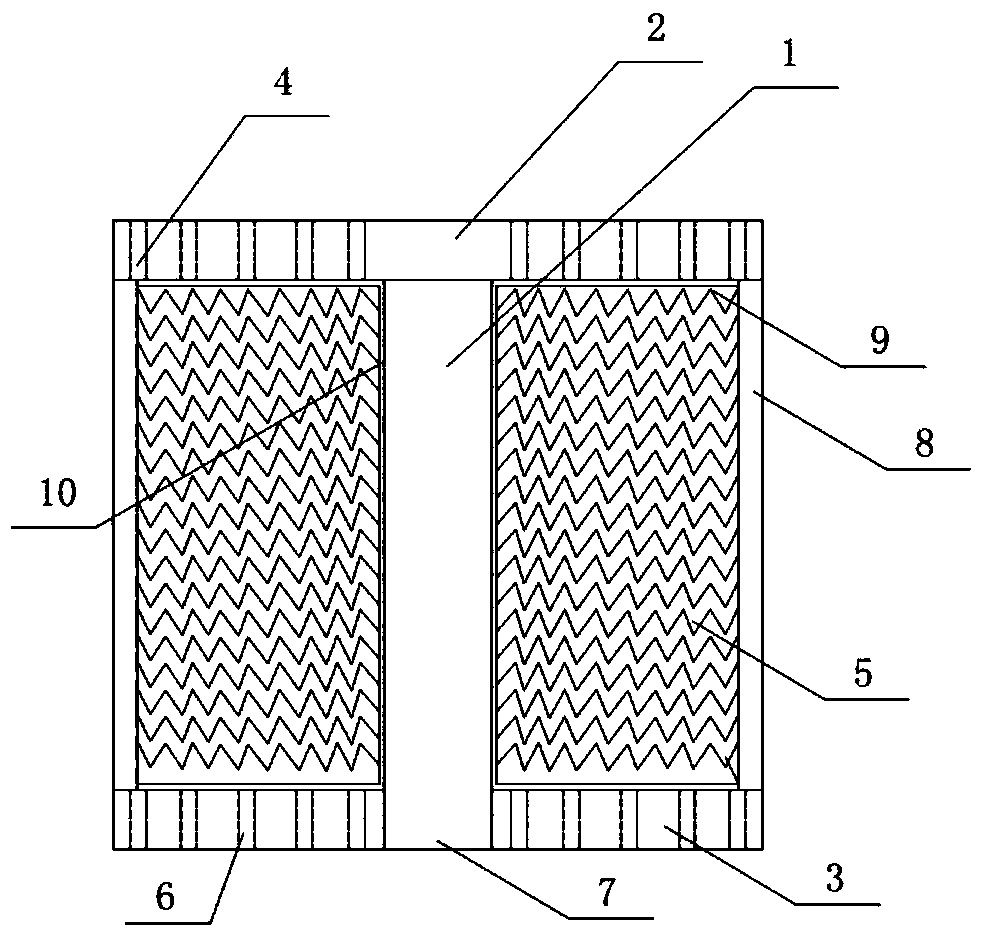

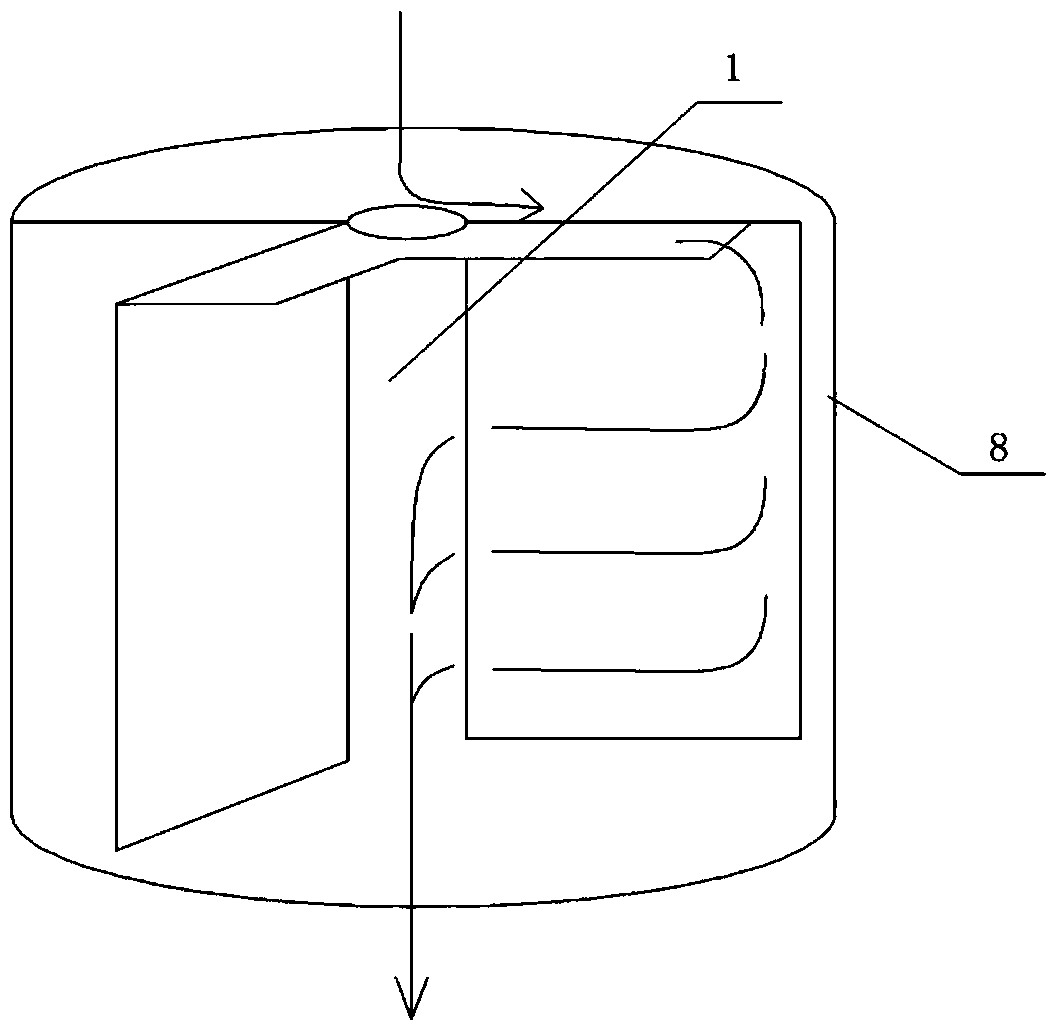

Method used

Image

Examples

Embodiment 1

[0036] A lubricating oil consisting of the following components in weight percent:

[0037] Water 55%; Sodium dodecylbenzenesulfonate 35%; Lipase 9.5%; Graphene 0.5%.

[0038] The lipase is an immobilized lipase, and the particle size of the graphene is 12000 mesh.

Embodiment 2

[0040] A lubricating oil consisting of the following components in weight percent:

[0041] Water 75%; Sodium Dodecyl Benzene Sulfonate 20%; Lipase 4.9%; Graphene 0.1%.

[0042] The lipase is an immobilized lipase, and the particle size of the graphene is 14000 mesh.

Embodiment 3

[0044] A lubricating oil consisting of the following components in weight percent:

[0045] Water 65%; Sodium Dodecylbenzene Sulfonate 26.7%; Lipase 8%; Graphene 0.3%.

[0046] The lipase is an immobilized lipase, and the particle size of the graphene is 13000 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com