Method for preparing environment-friendly alpha-arbutin by using bioenzyme reaction and water crystallization purification

An environmentally friendly and arbutin technology, applied in fermentation and other directions, can solve the problems of difficulty in ensuring the complete removal of organic solvents, large safety hazards, and low efficiency, and achieve low cost, low allergenicity, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

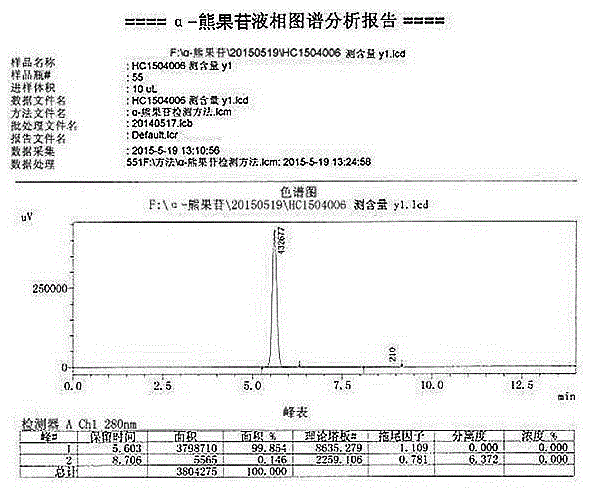

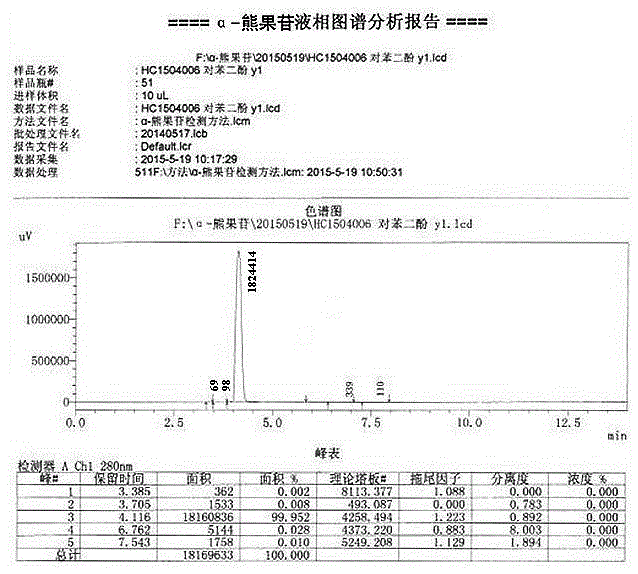

Image

Examples

Embodiment 1

[0038] A method for preparing environmentally friendly α-arbutin by using biological enzyme reaction and water crystallization purification includes biological enzyme synthesis of α-arbutin and water crystallization separation and purification of α-arbutin; biological enzyme synthesis of α-arbutin enzyme The components of the reaction bottom solution (in total weight percentage) are 5.0%~15.0% of disaccharide, 0.5%~5.0% of 1,4-hydroquinone, 0.02%~0.08% of sodium hydroxide, and 0.1%~2.0% of auxiliary agent and the remaining amount of purified water; add 5-50g / L α-arbutinase to the enzyme reaction bottom solution, and react at 30-50°C to obtain the initial product solution of α-arbutin.

[0039] The biological enzyme synthesis α-arbutin is prepared by the following method:

[0040] (1) Weigh 10.0% disaccharide and 1.5% auxiliary agent, add purified water and stir to dissolve;

[0041] (2) Add sodium hydroxide to adjust the pH value to 6.5, then add 1.0% 1,4-hydroquinone, stir a...

Embodiment 2

[0054] A method for preparing environmentally friendly α-arbutin by using biological enzyme reaction and water crystallization purification, including biological enzyme synthesis of α-arbutin and water crystallization separation and purification of α-arbutin, biological enzyme synthesis of α-arbutin The components of the enzyme reaction bottom liquid (in total weight percentage) are 5.0%~15.0% of disaccharide, 0.5%~5.0% of 1,4-hydroquinone, 0.02%~0.08% of sodium hydroxide, and 0.1%~2.0% of auxiliary agent % and the rest of purified water, add 5-50g / L α-arbutinase to this enzyme reaction bottom solution, and react at 30-50°C to obtain the initial product solution of α-arbutin.

[0055] The biological enzyme synthesis α-arbutin is prepared by the following method:

[0056] (1) Weigh 8.0% disaccharide and 1.2% auxiliary agent, add purified water and stir to dissolve;

[0057] (2) Add sodium hydroxide to adjust the pH value to 6.0, then add 1.0% 1,4-hydroquinone, stir to dissolve...

Embodiment 3

[0070] A method for preparing environmentally friendly α-arbutin by using biological enzyme reaction and water crystallization purification includes biological enzyme synthesis of α-arbutin and water crystallization to separate and purify α-arbutin, and biological enzyme synthesis of α-arbutin enzyme The components of the reaction bottom solution (in total weight percentage) are 5.0%~15.0% of disaccharide, 0.5%~5.0% of 1,4-hydroquinone, 0.02%~0.08% of sodium hydroxide, and 0.1%~2.0% of auxiliary agent And the remaining amount of purified water, add 5-50g / L α-arbutinase to the enzyme reaction base solution, and react at 30-50°C to obtain the initial product solution of α-arbutin.

[0071] The biological enzyme synthesis α-arbutin is prepared by the following method:

[0072] (1) Weigh 10.0% disaccharide and 1.5% auxiliary agent, add purified water and stir to dissolve;

[0073] (2) Add sodium hydroxide to adjust the pH value to 6.5, then add 1.0% 1,4-hydroquinone, stir and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com