Efficient environment-friendly penetrant for fabric pretreatment and preparation method thereof

A penetrant and high-efficiency technology, used in fiber treatment, plant fibers, textiles and papermaking, etc., can solve problems such as poor environmental performance, environmental hazards, and difficult wastewater treatment, and achieve low equipment requirements, low production costs, and low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

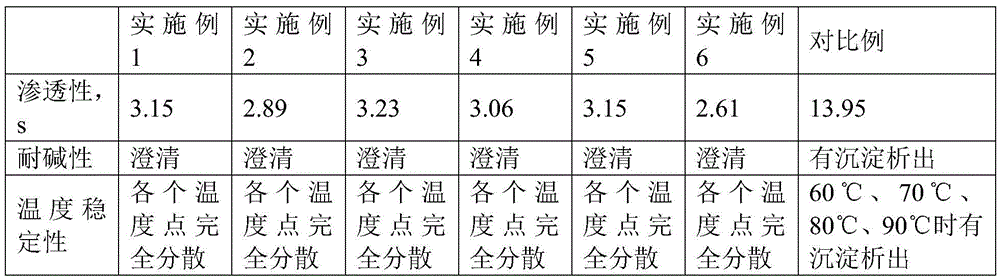

Examples

Embodiment 1

[0043] A high-efficiency environment-friendly penetrating agent for fabric pretreatment, in parts by weight, comprising the following components:

[0044] Dioctyl sodium sulfosuccinate 5 parts,

[0045] 2 parts of isomerized tridecanol polyoxyethylene ether,

[0046] 4 parts of sodium secondary alkyl sulfonate,

[0047] 2 parts polyoxyethylene oleate,

[0048] 1 part of phytic acid, 5 parts of alkyl glycoside,

[0049] 2 parts of sodium α-alkenyl sulfonate,

[0050] 6 parts of sodium N-dodecyl-β-alanine,

[0051] 2 parts methyl salicylate, 4 parts cloves,

[0052] 1 part defoamer, 1 part wetting agent,

[0053] 40 parts of deionized water.

[0054] Its preparation method comprises the following steps:

[0055] (1) Mix and stir isomeric tridecyl alcohol polyoxyethylene ether, polyoxyethylene oleate, methyl salicylate, clove and deionized water evenly, heat up to 40°C, and stir at 5000 rpm 1h, the mixture was obtained;

[0056] (2) Cool the mixed solution obtained in s...

Embodiment 2

[0058] A high-efficiency environment-friendly penetrating agent for fabric pretreatment, in parts by weight, comprising the following components:

[0059] Dioctyl sodium sulfosuccinate 10 parts,

[0060] 4 parts of isomerized tridecanol polyoxyethylene ether,

[0061] 7 parts of sodium secondary alkyl sulfonate,

[0062] 3 parts polyoxyethylene oleate,

[0063] 3 parts of phytic acid, 8 parts of alkyl glycoside,

[0064] 6 parts of sodium α-alkenyl sulfonate,

[0065] 12 parts of sodium N-dodecyl-β-alanine,

[0066] 5 parts of methyl salicylate, 6 parts of cloves,

[0067] 2 parts of defoamer, 2 parts of wetting agent,

[0068] 80 parts of deionized water.

[0069] Its preparation method comprises the following steps:

[0070] (1) Mix and stir isomeric tridecyl alcohol polyoxyethylene ether, polyoxyethylene oleate, methyl salicylate, clove and deionized water evenly, heat up to 50°C, and stir at 8000 rpm 3h, obtain mixed solution;

[0071](2) Cool the mixed solution ...

Embodiment 3

[0073] A high-efficiency environment-friendly penetrating agent for fabric pretreatment, in parts by weight, comprising the following components:

[0074] Dioctyl sodium sulfosuccinate 8 parts,

[0075] 3.5 parts of isomerized tridecanol polyoxyethylene ether,

[0076] 6 parts of sodium secondary alkyl sulfonate,

[0077] 2 parts polyoxyethylene oleate,

[0078] 1 part of phytic acid, 6 parts of alkyl glycoside,

[0079] 4.5 parts of sodium α-alkenyl sulfonate,

[0080] 11 parts of sodium N-dodecyl-β-alanine,

[0081] 3 parts methyl salicylate, 5 parts cloves,

[0082] 1.5 parts of defoamer, 1 part of wetting agent,

[0083] 80 parts of deionized water.

[0084] Its preparation method comprises the following steps:

[0085] (1) Mix and stir isomeric tridecyl alcohol polyoxyethylene ether, polyoxyethylene oleate, methyl salicylate, clove and deionized water evenly, heat up to 40°C, and stir at 6000 rpm 1.5h, the mixture was obtained;

[0086] (2) Cool the mixed soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com