Intelligent energy-saving pumping unit and its automatic control method

A kind of oil pumping unit, intelligent technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of rough balance adjustment, too light balance, high energy consumption, etc., to reduce the energy transmission path and achieve accurate balance. The effect of improving the degree and improving the efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

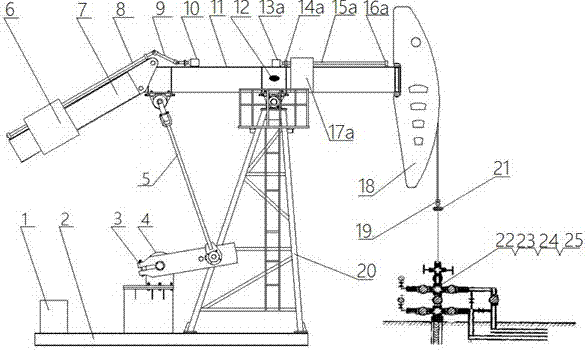

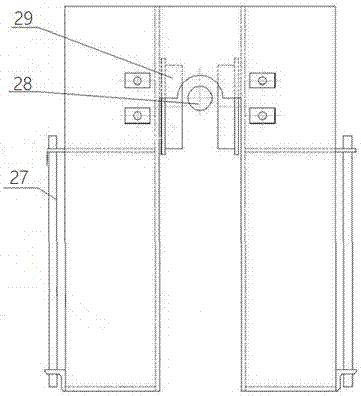

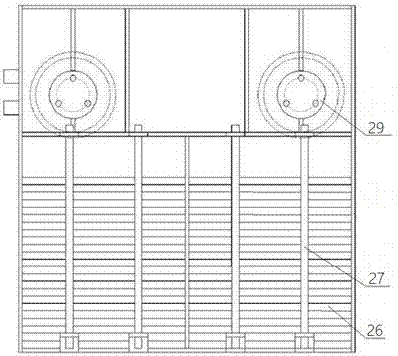

[0037] see figure 1 , figure 2 , image 3 , an intelligent energy-saving pumping unit includes a beam 11, a donkey head 18, a tail beam 7, a bracket 20, a base 2, a main motor 4, a crank 3, a connecting rod 5, a rope suspension 19, an intelligent control cabinet 1 and several The working condition sensor, the working condition sensor includes the load sensor 21 located on the rope hanger 19, the angular displacement sensor 12 located on the upper part of the connection between the beam 11 and the support 20, and the liquid level sensor 22, pressure sensor 23, flow rate sensor located on the wellhead respectively. The transmitter 24 and the temperature and humidity sensor 25 are provided with a tail beam balancing device at the tail end of the beam 11, which includes a tail beam counterweight box 6 assembled on the tail beam 7 body and a stepping motor that drives the counterweight box to move 10. The stepper motor 10 is set on the beam 11, connected with the sliding screw 8...

Embodiment 2

[0048] see Figure 5 The difference between this embodiment and Embodiment 1 is that when the beam 11 adopts a rectangular cylinder structure, the built-in balance fine-tuning device is arranged in the beam body, and the device includes the Servomotor 13b, left bearing 14b and right bearing 16b in the beam 11 body, the leading screw 15b that is parallel with swimming beam 11 is arranged between left bearing 14b and right bearing 16b, and this leading screw is connected with servomotor 13b, The lead screw 15b is equipped with a fine-tuning counterweight lead block 17b threadedly connected with it.

[0049] see Image 6 It is a control system block diagram of the present invention, and the automatic control method of the intelligent pumping unit of the present invention comprises the following steps:

[0050] (1) Startup: the power frequency power supply is introduced into the electronic control unit, and the main drive module of the electronic control unit automatically selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com