An anti-gravity heat pipe

An anti-gravity and heat pipe technology, applied in the field of heat pipes, can solve the problems of increasing heat load, limited effect, complex structure, etc., and achieve the effect of increasing convective heat transfer, simple structure and strong driving ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

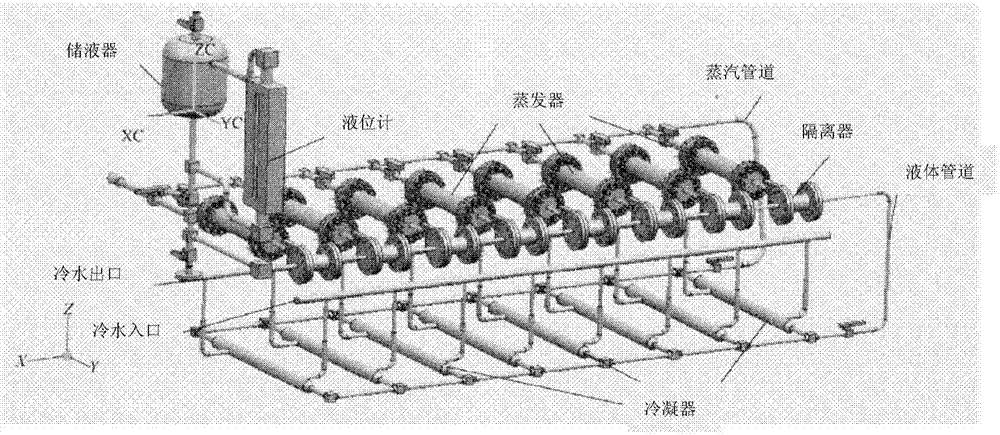

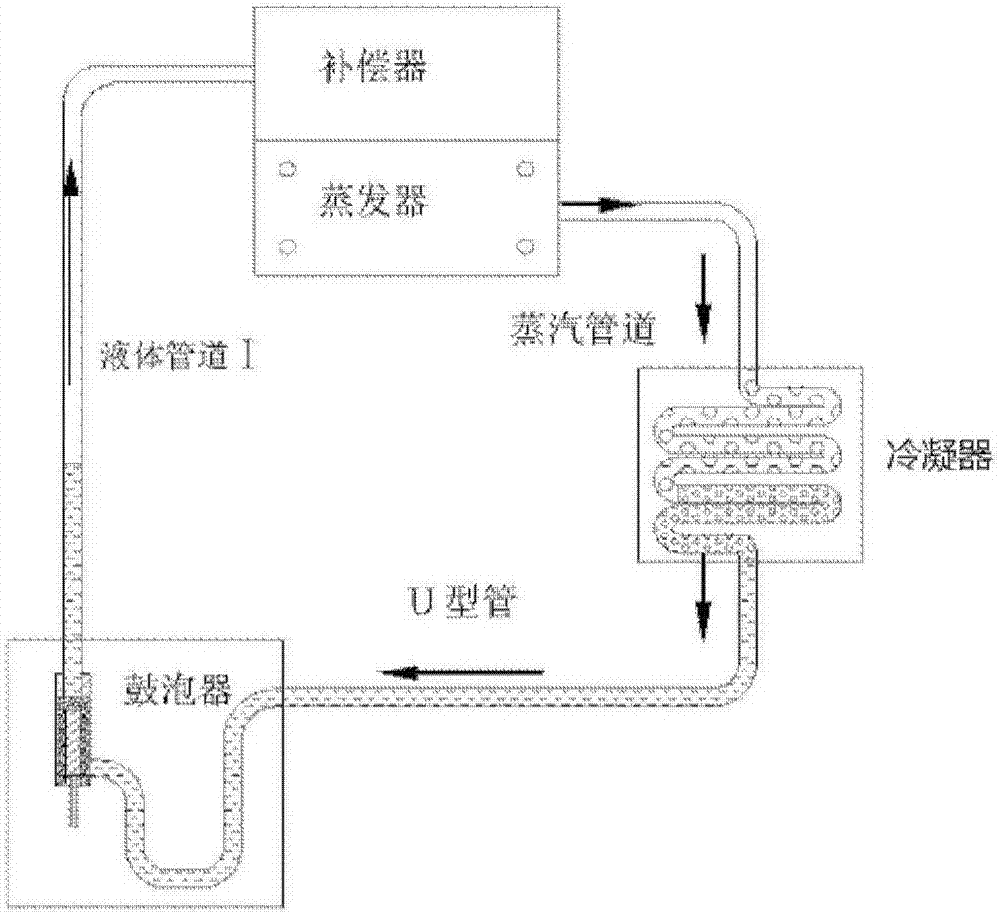

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

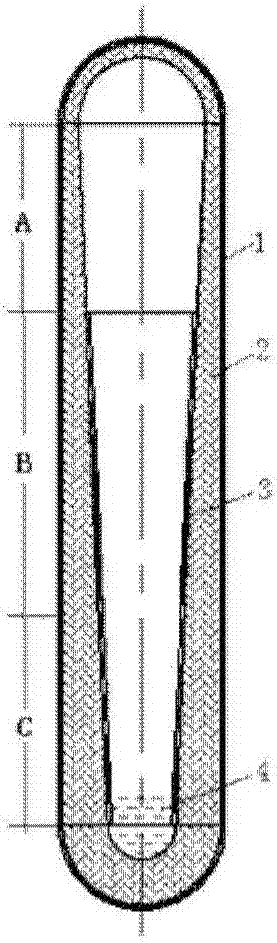

[0044] The invention arranges a shape memory spring in the heat pipe, and according to the shape memory effect, the shape memory spring is heated and deformed to generate a driving force, so that the working medium circulates against gravity and realizes antigravity heat transfer.

[0045]Shape memory alloy is a solid material with a certain shape (usually a material with a thermoelastic martensitic phase transition), which undergoes plastic deformation with a certain amount of deformation under low temperature conditions. When the alloy is heated to a certain temperature, the material can recover to The initial shape before deformation. After the shape memory spring is trained, when it reaches a certain temperature condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com