Light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and two-dimensional electronic gas, which is applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as unfavorable current lateral expansion, overheating breakdown of light-emitting devices, damage to MQW layer 20, etc., so as to improve local overheating vulnerability. Wear features, increase horizontal expansion ability, and improve the effect of antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below with reference to the drawings and embodiments.

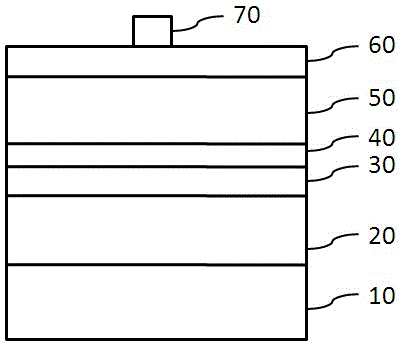

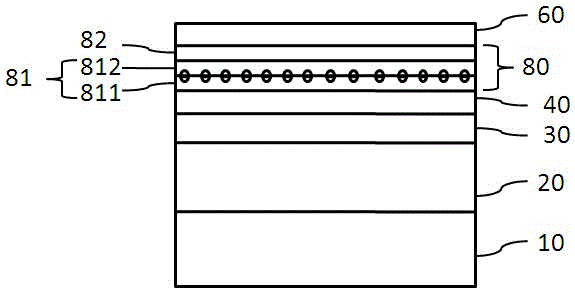

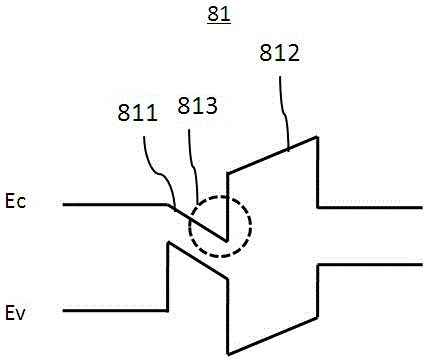

[0028] See attached figure 2 , a light-emitting diode designed in the present invention, at least including: N-type layer 10, active layer 20, low-temperature P-type GaN layer 40 located on active layer 20, non-P-type nitride layer 80 and P-type contact Layer 60, wherein the N-type impurity is any one of silicon, germanium, and tin, which is used to provide electrons, and the P-type impurity is any one of beryllium, magnesium, calcium, strontium, and barium, which is used to provide holes; The active layer 20 is a periodic structure composed of InGaN well layers and GaN barrier layers, and its period number is 4-12. The low-temperature P-type GaN layer 40 is a hole injection layer located on the active layer 20 , which reduces the migration distance of holes during effective recombination of electrons and holes and increases r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com