Optically pumped light emitting device and preparation method of monolithically integrated optically pumped light emitting device

A light-emitting device, monolithic integration technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of not being able to meet the lighting industry, reduce compressive stress, and insufficient strength, so as to reduce compressive stress, reduce loss, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of the above-mentioned monolithic integrated optically pumped light-emitting device includes the following steps:

[0062] 1) Provide substrate 1: provide a cleaned single-sided polished substrate 1, the material of substrate 1 includes any one of these materials: (0001) surface sapphire, (0001) surface gallium nitride single crystal and (0001) surface aluminum nitride single crystal; when the unit body 3 is nitrogen polar, the substrate 1 is intentionally beveled, thereby deviating from the [0001] direction by 0-6°, and the deviating direction can be toward the (1-100) of the substrate 1 ) plane or (11-20) plane, or between the (1-100) plane and (11-20) plane facing the substrate 1; the thickness of the substrate 1 is preferably 0.4-5mm, and the transparency is preferably 385nm- In the 500nm spectral range, the transmittance is not lower than 60%; in this step, the double-sided polished substrate 1 cannot be used, because the polished other side ...

Embodiment 1

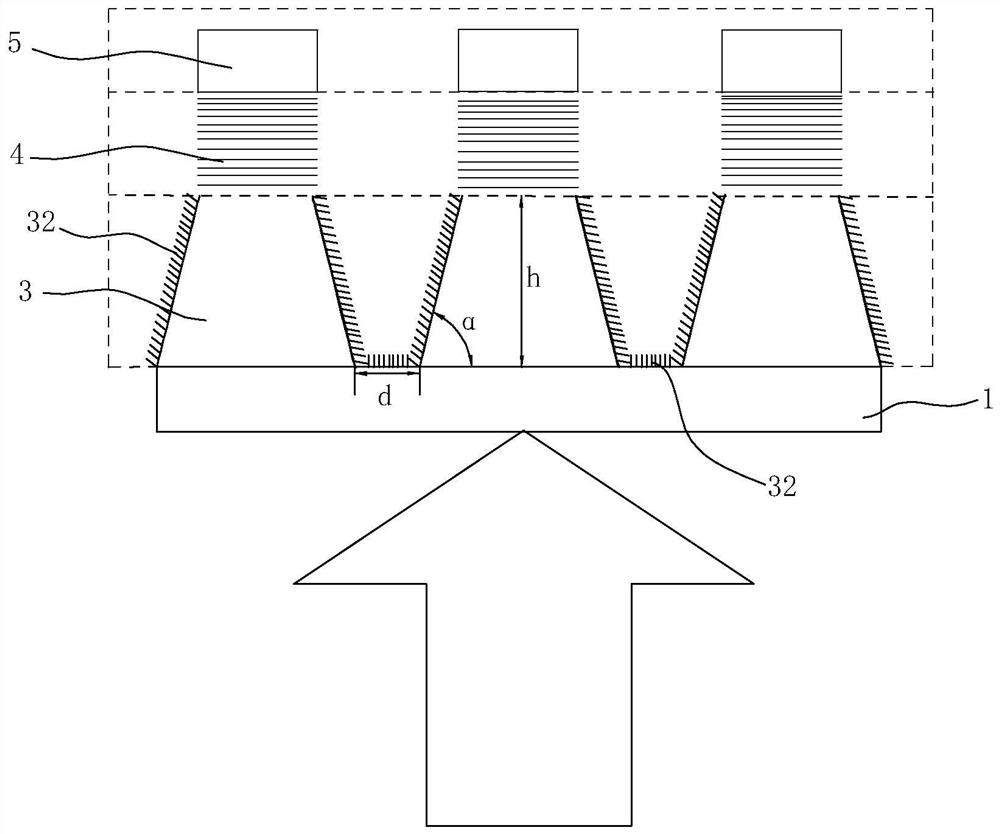

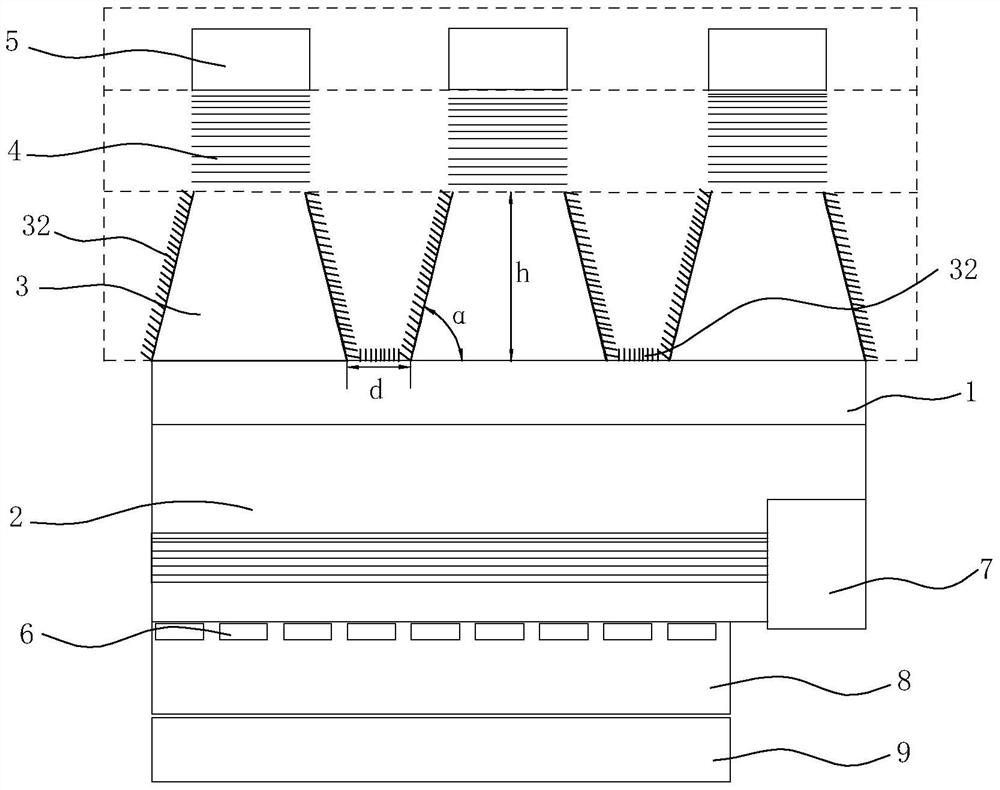

[0075] see image 3 with Figure 4 , In this embodiment, the substrate 1 is an undoped (0001) sapphire substrate with a thickness of 0.6mm.

[0076] The nitride structure 2 of the blue-violet light LED includes sequentially arranged from top to bottom: I) unintentionally doped GaN 2a, with a preferred thickness of 2 μm. It includes a 30nm GaN low-temperature nucleation layer; II) an n-type GaN layer 2b doped with Si, preferably with a thickness of 2.0 μm and a Si doping concentration of 3×10 +18 cm -3 ; III) Blue-violet light quantum well 2c, including 7 pairs, its composition is In x Ga 1-x N(0.01≤x≤0.30), preferably In 0.14 Ga 0.86 N(2nm) / Si:GaN(7nm), Si doping concentration is 1×10 +18 cm -3 and IV) Mg-doped p-type nitride layer 2d: its composition is Mg:Al 0.25 GaN 0.75 (10nm) / Mg:GaN, the preferred thickness is 350nm, and the Mg doping concentration is 3×10 +19 cm -3 . In this embodiment, the light emitting wavelength of the nitride structure 2 of the blue-vio...

Embodiment 2

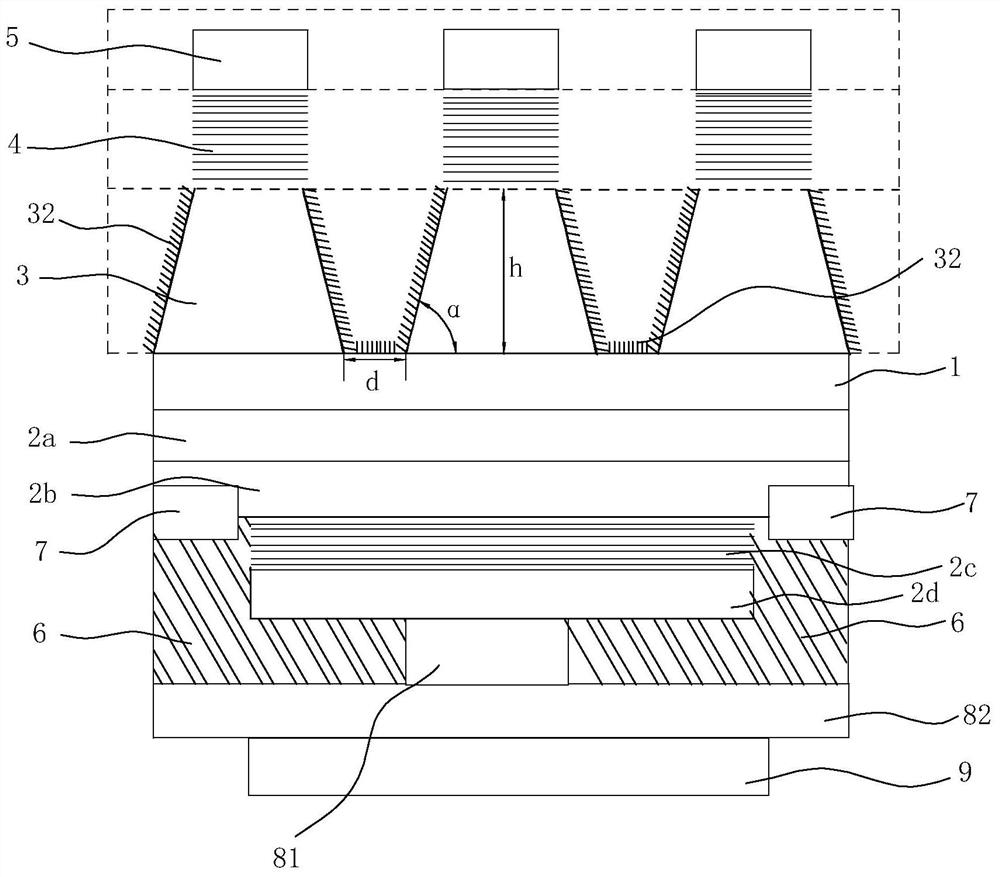

[0096] see Figure 5 with Image 6 , in this embodiment, the substrate 1 is an undoped beveled (0001) sapphire substrate with a thickness of 0.6 mm, the bevel rotation axis is [1-100], and the bevel angle is 1.2°. Chamfering helps reduce hexagonal surface defects during the growth of nitrogen-polar GaN required to form the unit body.

[0097] The nitride structure 2 of the blue-violet light LED includes sequentially arranged from top to bottom: I) unintentionally doped GaN 2a, preferably with a thickness of 2 μm, including GaN low-temperature nucleation layer (30nm); II) n-type doped Si The GaN layer 2b has a preferred thickness of 2.0 μm and a Si doping concentration of 3×10 +18 cm -3 ; III) blue-violet light quantum well 2c, including 7 pairs, its composition In 0.14 Ga 0.86 N(2nm) / Si:GaN(7nm), Si doping concentration is 1×10 +18 cm -3 and IV) Mg-doped P-type nitride layer 2d: its composition is Mg:Al 0.25 GaN 0.75 (10nm) / Mg:GaN, the preferred thickness is 350nm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com