A small and medium-scale distributed natural gas steam reforming hydrogen production system and method

A technology for reforming hydrogen and natural gas, applied in electrical components, fuel cells, electrochemical generators, etc., can solve heat transfer efficiency, temperature distribution, hot spot control, amplification processing difficulty, safety, reduce reformer tube length, reactor Small scale and other problems, to avoid high temperature thermal stress, improve the rationality of energy utilization, and save consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

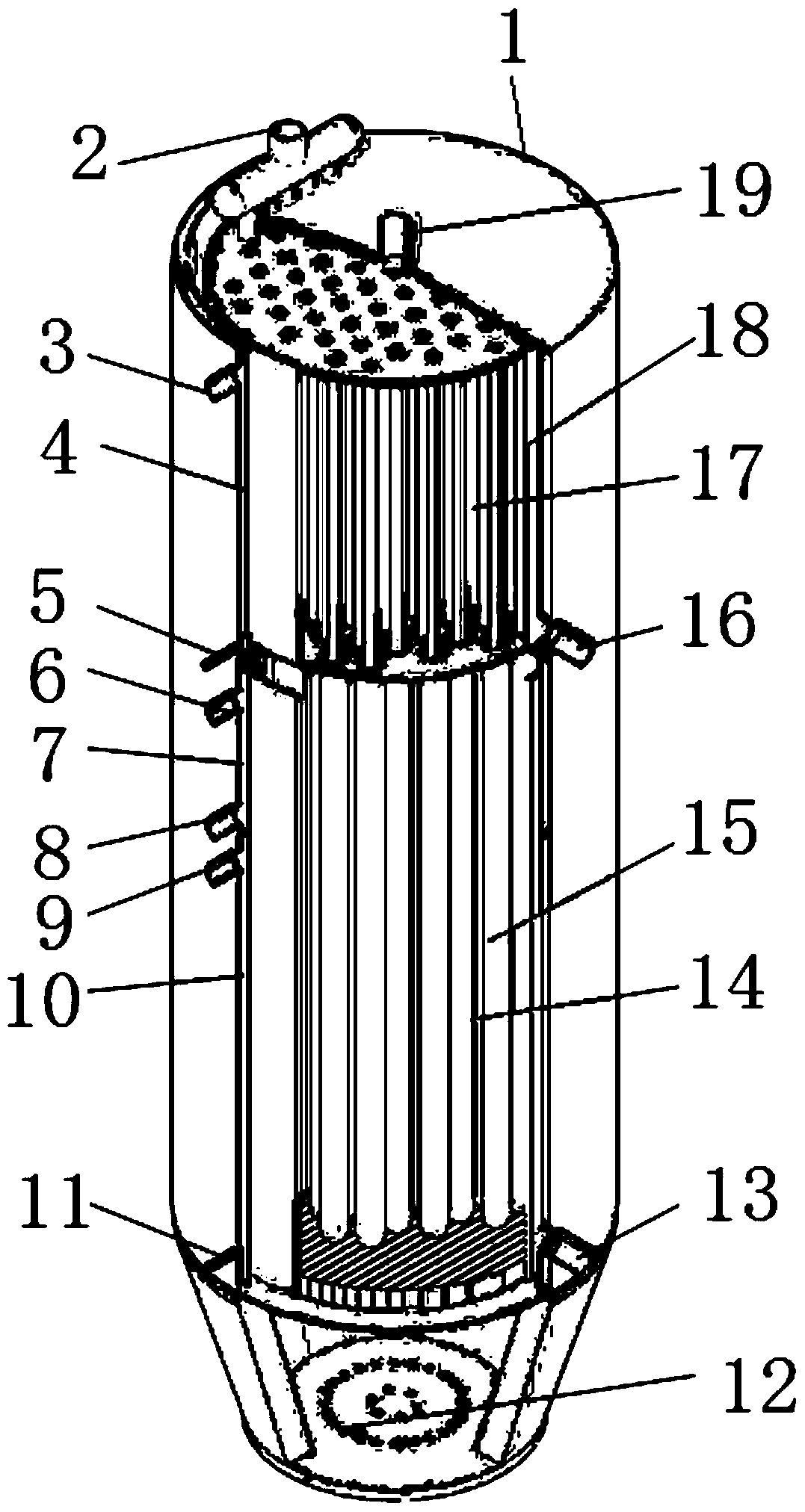

Image

Examples

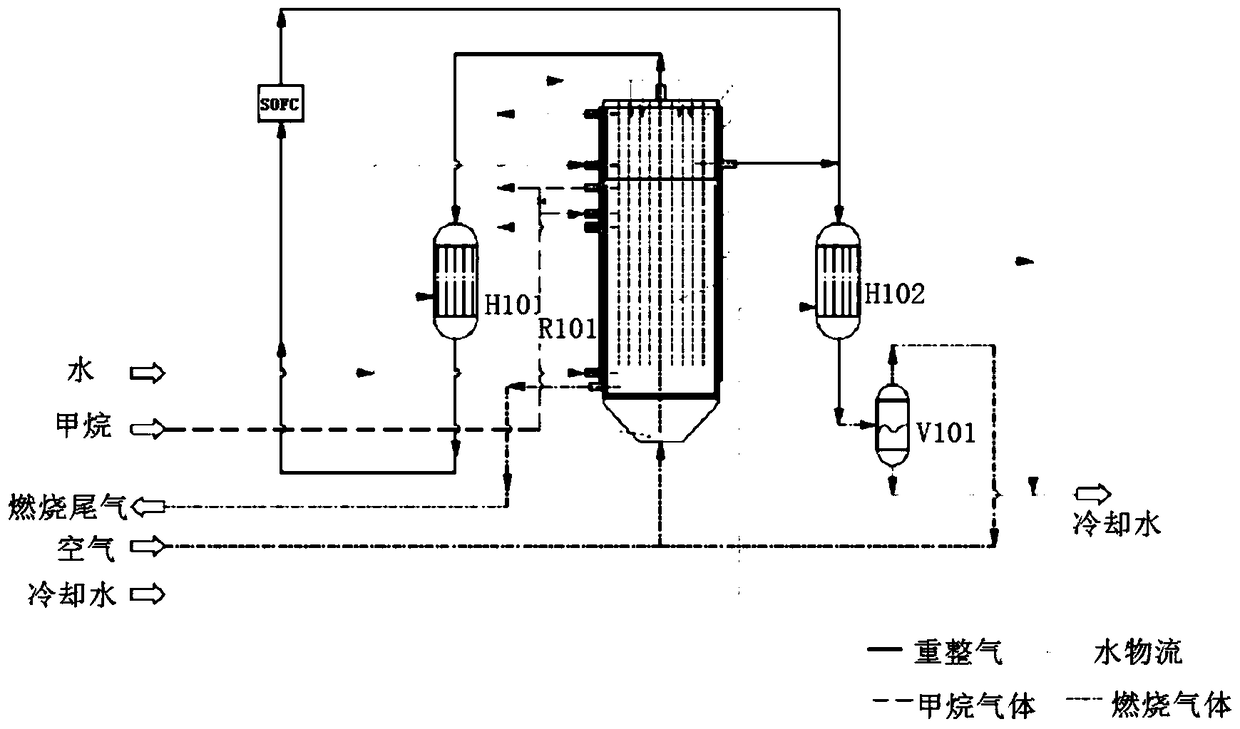

Embodiment 1

[0038] A distributed small and medium-sized natural gas steam reforming hydrogen production and SOFC combined system such as figure 2 shown. When the system is started, the normal temperature fuel methane and air are mixed into the burner to ignite and burn to generate high-temperature flue gas, which flows upward through the shell side of the central cavity of the integrated reactor (R101), preheating the reforming reaction tubes equipped with the reforming catalyst, The high-temperature flue gas turns back at the upper end of the R101 central cavity and enters the flue gas waste heat cooler in the central layer of the R101 jacket downwards to preheat the raw materials methane and water for the reforming reaction. The combustion flue gas after heat exchange is finally discharged out of the boundary through the combustion tail gas outlet at the bottom of R101. When the temperature of the methane preheater and water preheater reaches 200°C, the raw material methane and water ...

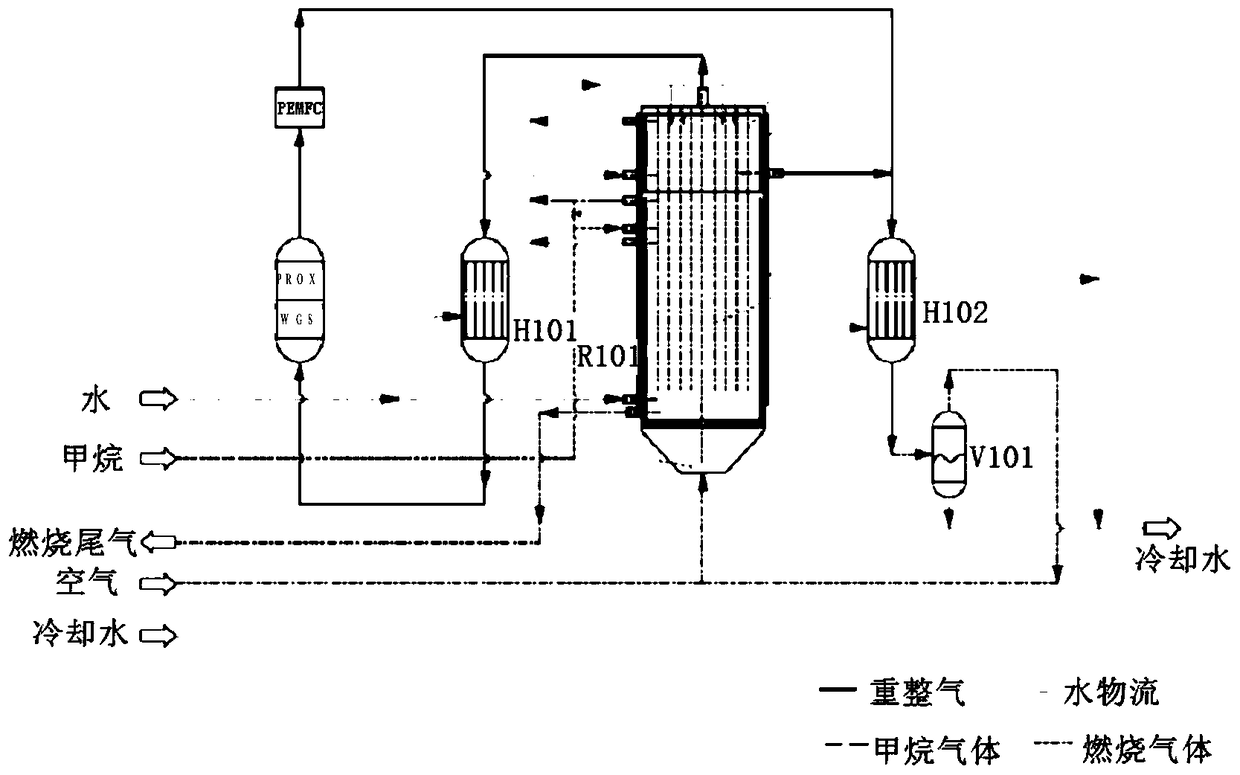

Embodiment 2

[0040] A distributed small and medium-sized natural gas steam reforming hydrogen production and PEMFC combined system such as image 3 shown. The technological process and operating parameters of the integrated reforming reactor R101 starting up and reaching normal operation are the same as those in Example 1. After the system reaches a normal operating state, the reformed product gas flows out from the top of R101 and enters the reformed gas waste heat evaporator H101 to continue preheating part of the raw water. Continue to enter the CO purification system consisting of two-stage CO water-steam shift unit, four-stage CO selective oxidation unit and interstage heat exchanger for reaction, so that the CO concentration in the reformed product gas is reduced to below 10ppm, and the reformed product gas Air temperature drops to 60-80°C. The product gas continues to enter the PEMFC anode for battery reaction to generate electricity. PEMFC anode tail gas contains 20-30% H 2 , t...

Embodiment 3

[0042] A distributed medium and small natural gas steam reforming hydrogen production system combined with a Pd membrane hydrogen separator such as Figure 4 shown. The technological process and operating parameters of the integrated reforming reactor R101 starting up and reaching normal operation are the same as those in Example 1. After the system reaches the normal operation state, the reformed product gas flows out from the top of R101 and enters the reformed gas waste heat evaporator H101 to continue preheating part of the raw material water. The temperature of the reformed product gas flowing out of H101 is 400-550°C. After the gas is pressurized to 2.5 MPa, it continues to enter the Pd membrane hydrogen separator to obtain pure hydrogen with a purity of 99.9%. The retentate gas of Pd membrane hydrogen separator contains 20-30% H 2 , the retentate gas enters H102 and V101 in turn for cooling, dehydration, and then enters R101 bottom burner for combustion, providing hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com