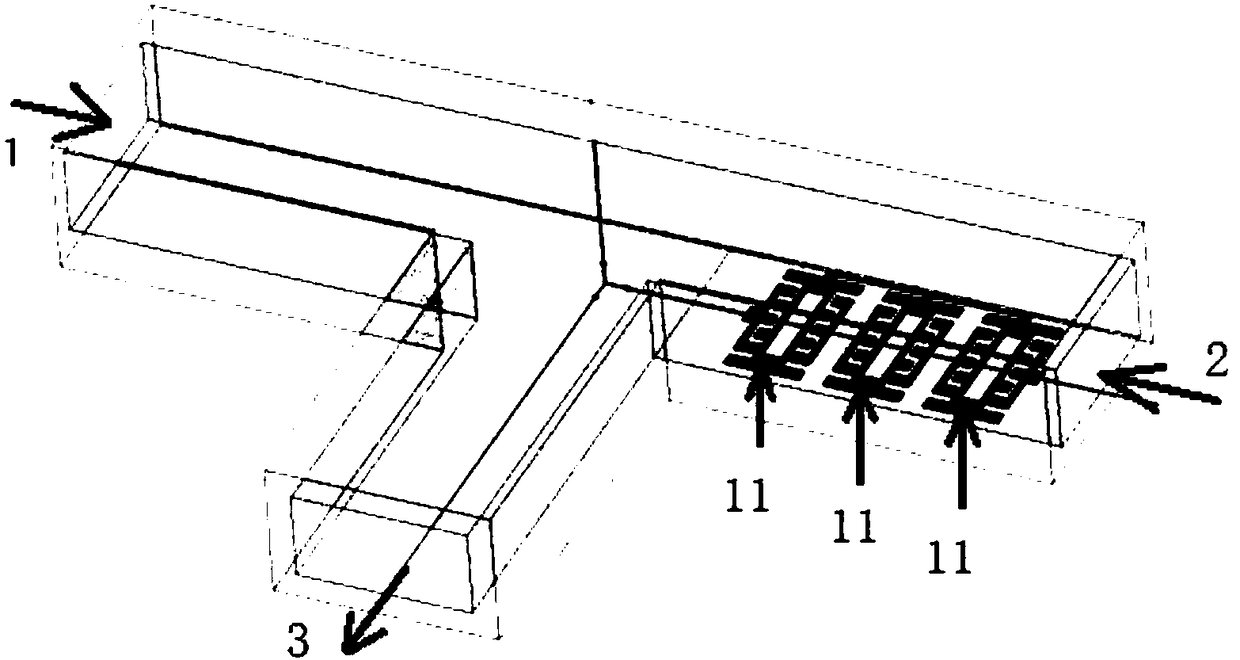

A waveguide t-type hybrid junction based on ferroelectric materials and its design method

A ferroelectric material and ferroelectric technology, used in waveguide devices, circuits, electrical components, etc., can solve problems such as low insertion loss, inability to achieve phase, and no research results, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

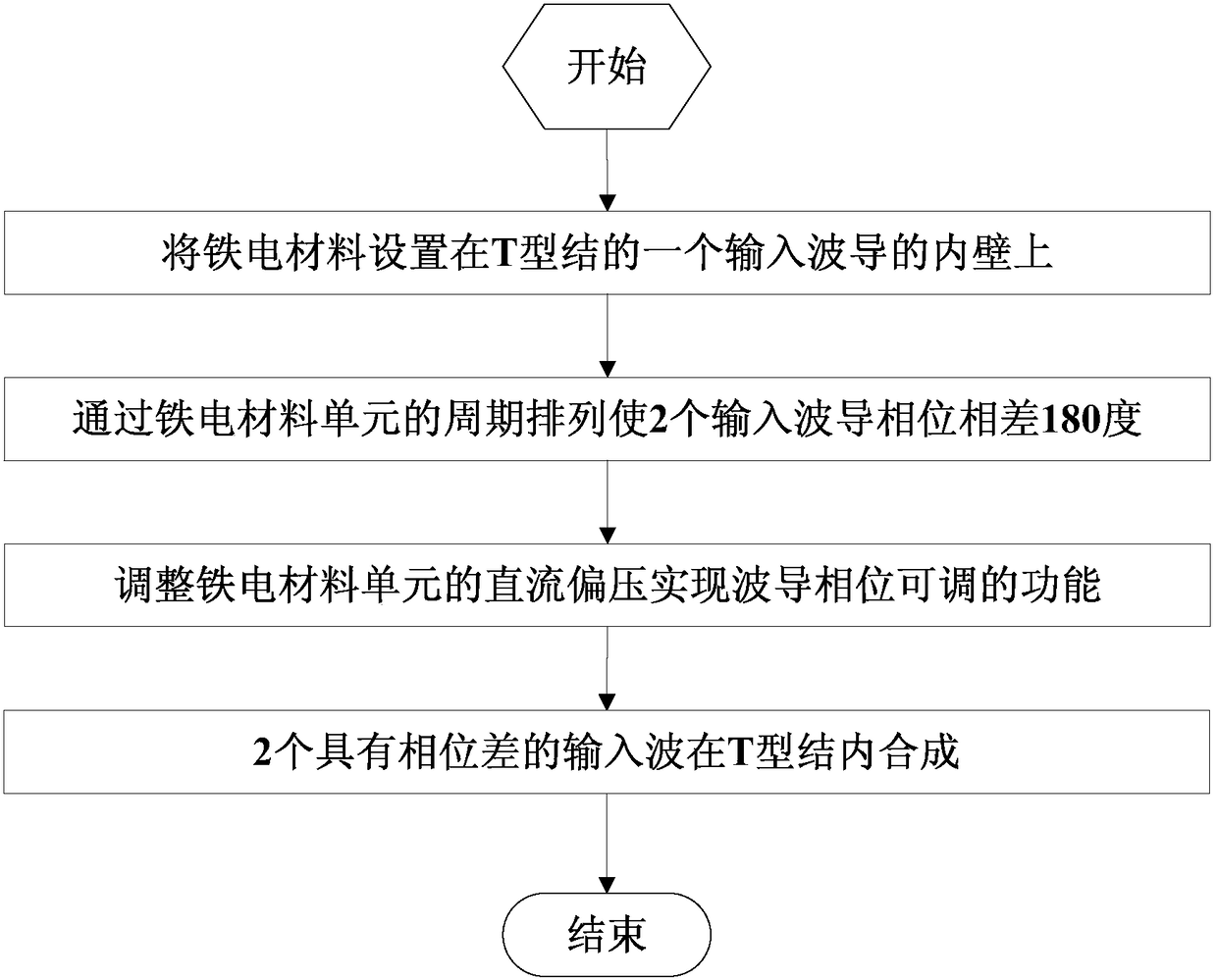

Method used

Image

Examples

Embodiment

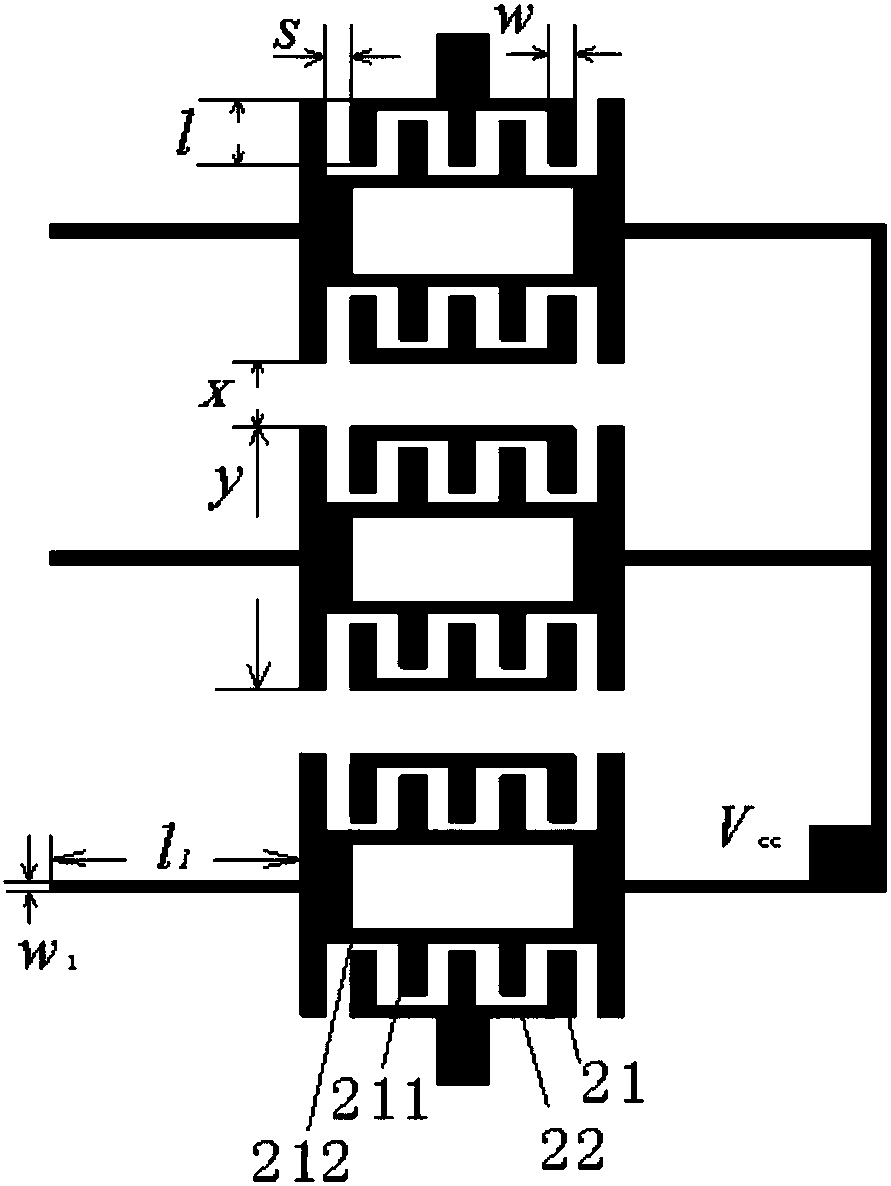

[0033] Embodiment: The ferroelectric material is ferroelectric strontium barium titanate thin film ferroelectric material (barium strontiumtitanate, BST), the dielectric constant is 240, the thickness of the medium is 0.01mm, and the thickness of the metal is 0.035mm. By optimizing the design, such as figure 2 As shown, when the length l of the first / second interdigital unit is 0.7mm, the width w is 0.5mm, the spacing s is 0.4mm, the length l1 of the narrow strip line is 0.5mm, and the width w1 is 0.2mm, the ferroelectric rectangular substrate The length y of the ferroelectric rectangular substrates is 3 mm, and the distance x between the ferroelectric rectangular substrates is 1 mm. When the DC bias voltage of the ferroelectric rectangular substrate is 130V, relative to the input wave of waveguide 1, the phase difference of the input wave of waveguide 2 can maintain 180°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com