Vanadium-based glass material for local heating and sealing, flat-panel display using the glass material, and method for manufacturing the display

A flat-panel display, local heating technology, applied in glass manufacturing equipment, glass molding, glass re-molding and other directions, to achieve high sealing, large sealing strength, excellent low temperature processability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

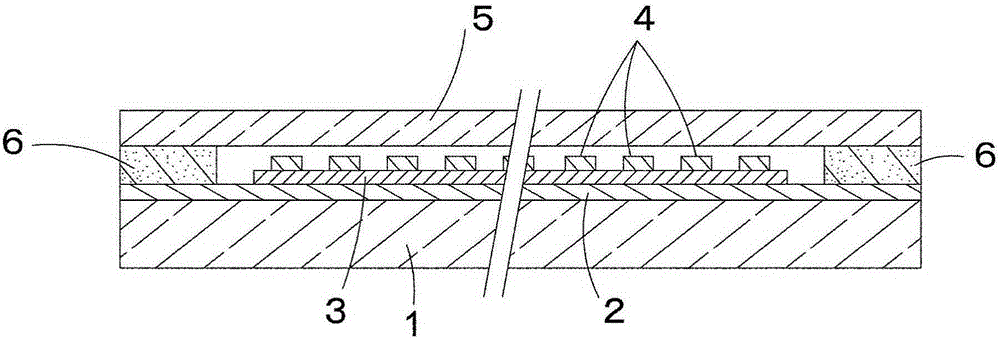

Image

Examples

manufacture example 1

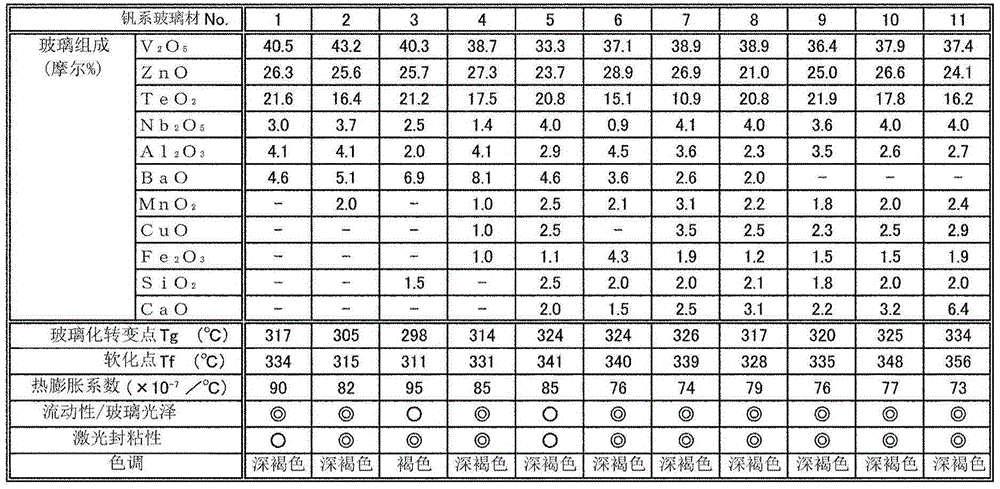

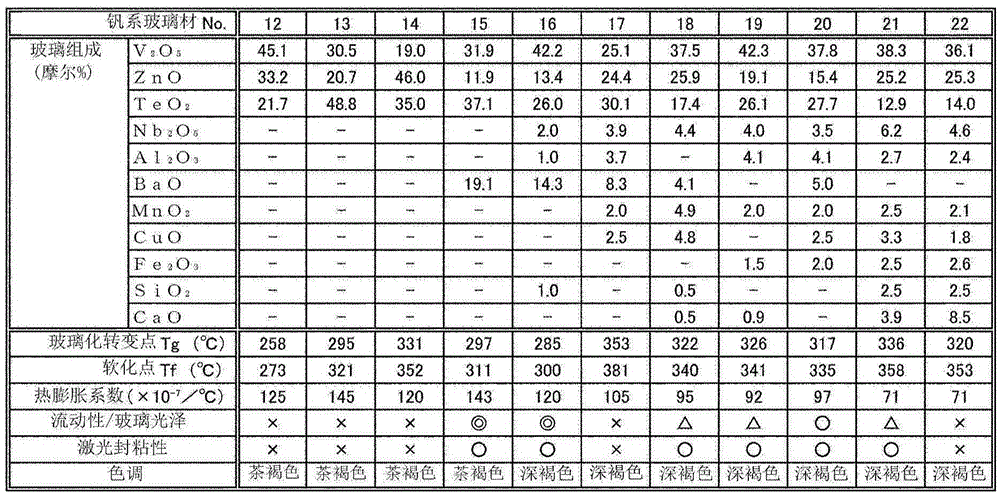

[0076] As the raw material oxide, the V 2 o 5 , BaO, TeO 2 , Nb 2 o 5 、Al 2 o 3 , ZnO, MnO 2 , CuO, Fe 2 o 3 , SiO 2 , CaO, P 2 o 5 The respective powders were mixed at the ratios (mol %) described in Tables 1 and 2 described below (10 g in total) and placed in a platinum crucible, heated in an electric furnace at about 1000° C. for 60 minutes to melt, and poured the melt into Put it into an alumina boat to make a glass ribbon, after cooling in the atmosphere, crush the glass ribbon with an automatic mortar, classify the crushed product, collect the crushed product with a particle size of 100 μm or less, and manufacture a powdered vanadium-based glass material No.1~22.

[0077] The glass transition point [Tg], softening point [Tf], thermal expansion coefficient, fluidity in molten state, glass gloss, laser sealing property, and color tone were examined for vanadium-based glass materials No. 1 to 22 produced by the above method. . The results are shown in Table 1 ...

manufacture example 2

[0101] The powders of vanadium-based glass materials No. 7 and No. 16 in Production Example 1 above were mixed with zirconium phosphate (maximum particle size: 5.5 μm, average particle size: about 1.0 μm) as fillers in the ratios shown in Table 3 below. , Manufactured filler-containing glass materials No.F1-F4. In addition, regarding these filler-containing glass materials No. F1 to F4, the coefficient of thermal expansion, laser sealing property, sealing strength, and color tone were examined, and the results are shown in Table 3. In addition, the measuring method and evaluation of thermal expansion coefficient, laser sealing property, and color tone are the same as that of Production Example 1. The measurement of the seal strength is as follows.

[0102] 〔Seal strength test〕

[0103] To 100 g of each of the filler-containing glass materials No. F1 to F4 obtained in Production Example 2 above, 20 g of a carrier containing ethyl cellulose / butyl carbitol acetate / terpineol was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com