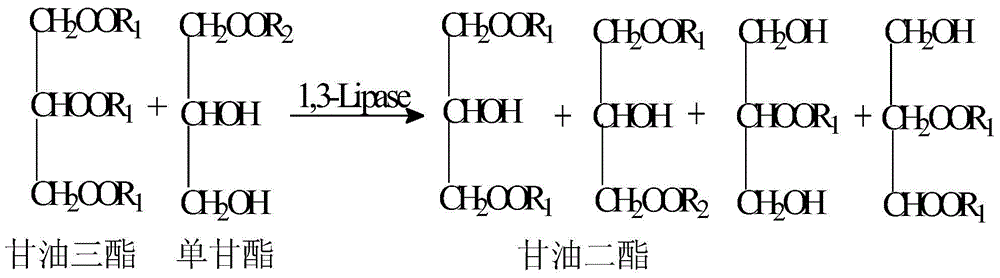

Method for preparing mixed monoglyceride and diglyceride contained food oil through enzyme catalysis

A technology for catalyzing preparation and diglyceride, applied in directions such as production/processing of edible oil/fat, can solve problems such as high cost and no reported mixed monoglycerides, etc., and achieve the effect of low saturated fatty acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

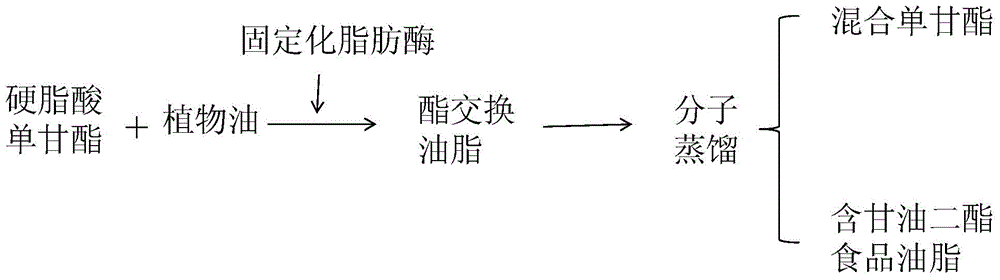

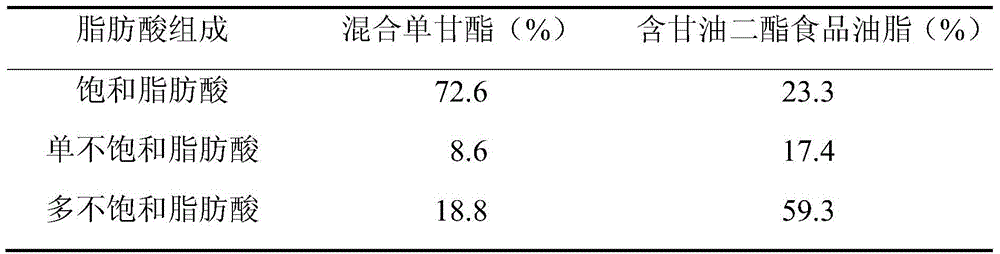

[0025] A method for preparing mixed monoglyceride and diglyceride-containing food oils and fats by enzyme-catalyzed transesterification, the method is as follows figure 2 shown, including the following steps:

[0026] (1) Get the mixture of 30.0g monoglyceride stearate and 70.0g soybean oil as the reaction substrate, add in the 250mL round bottom flask, after the mixture is completely melted in 60 ℃ water bath, add 5% (based on substrate total mass) of Novozymes LipozymeTLIM immobilized lipase as a catalyst, rotate at 100rpm (rotate instead of stirring, reduce shear force, prevent enzyme particle rupture) for 5h, remove enzyme to obtain crude DAG product.

[0027] The resulting crude DAG product was detected by gas chromatography. 50.0 mg of the crude DAG product was dissolved in 5.0 mL of acetone, and filtered with a 0.45 μm filter membrane.

[0028] Gas chromatography conditions: DB-1ht capillary column (15m×0.25mm, 0.1μm), inlet temperature 380°C, split ratio 40:1, press...

Embodiment 2

[0043] This implementation example is the same as Example 1 except for the following technical features: the enzyme addition amount described in step (1) is 1% (based on the total mass of the substrate), the reaction time is 2h, and the reaction temperature is 50°C. Finally, a crude DAG product is obtained. The crude product is separated and purified by molecular distillation to obtain food oil containing diglyceride, and the molecular distillation temperature in step (2) is 180°C.

[0044] Detected by the method described in Example 1, the content of diglyceride in the crude product obtained after the step (1) transesterification of this example is 4.0%; after molecular distillation, the food oil containing diglyceride is obtained, and the content of the oil in the oil is 4.0%. The diglyceride content is 6.7%.

Embodiment 3

[0046] This implementation example is the same as Example 1 except for the following technical features: the enzyme addition amount described in step (1) is 3% (based on the total mass of the substrate), the reaction time is 5h, and the reaction temperature is 55°C. Finally, a crude DAG product is obtained. The crude product is separated and purified by molecular distillation to obtain food oil containing diglyceride, and the molecular distillation temperature in step (2) is 190°C.

[0047] Detected by the method described in Example 1, the content of diglyceride in the crude product obtained after the step (1) transesterification reaction of this example is 9.3%; after molecular distillation, the food oil containing diglyceride is obtained, and the content of diacylglycerol in the oil is The diglyceride content is 15.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com