Catalyst for hydrogenation of dimethyl oxalate to methyl glycolate and ethylene glycol and preparation method thereof

A technology of methyl glycolate and dimethyl oxalate, which is applied in the direction of carboxylate preparation, catalyst carrier, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low mechanical strength of catalyst and poor performance of hydrogenation reaction , poor stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

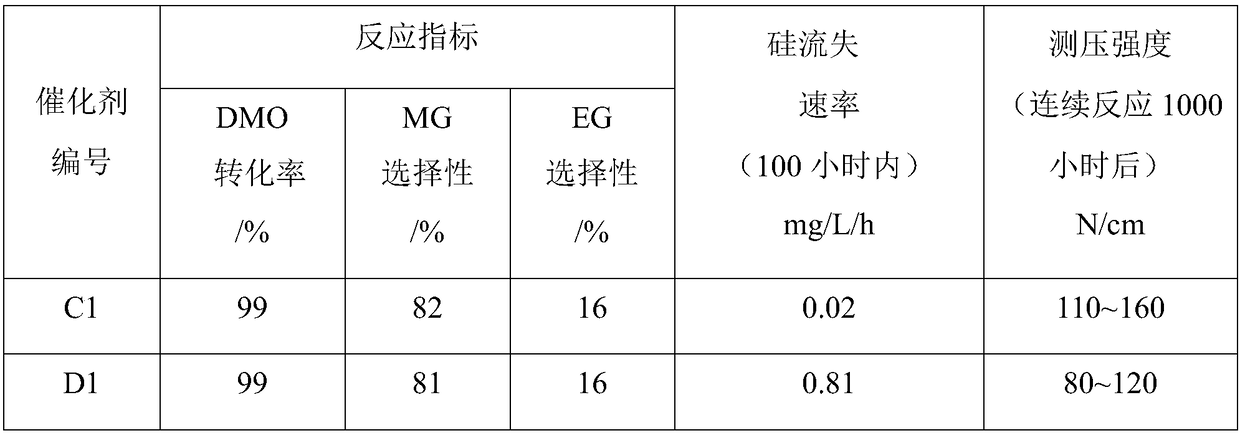

[0029] Weigh 700g of calcium nitrate tetrahydrate, 600g of white carbon black and 2000g of water and mix evenly. The above mixture continues to stand for 1 hour and then dried at 130°C for 8 hours. The dried solid is roasted in a muffle furnace at 650°C for 4 hours to obtain the required carrier. Weigh 64.0g of silver nitrate and dissolve it in 1100g of water to prepare solution R1, then add the above carrier for impregnation, let stand at room temperature for 2 hours and then dry at 130°C for 10 hours; the dried solid is calcined at 500°C for 4 hours. The solid obtained after calcination was pressed into a cylinder by a tablet machine, with a size of 5*5mm. The pressure test strength of the solid catalyst after forming was 110-160N / cm, and the obtained catalyst was numbered C1.

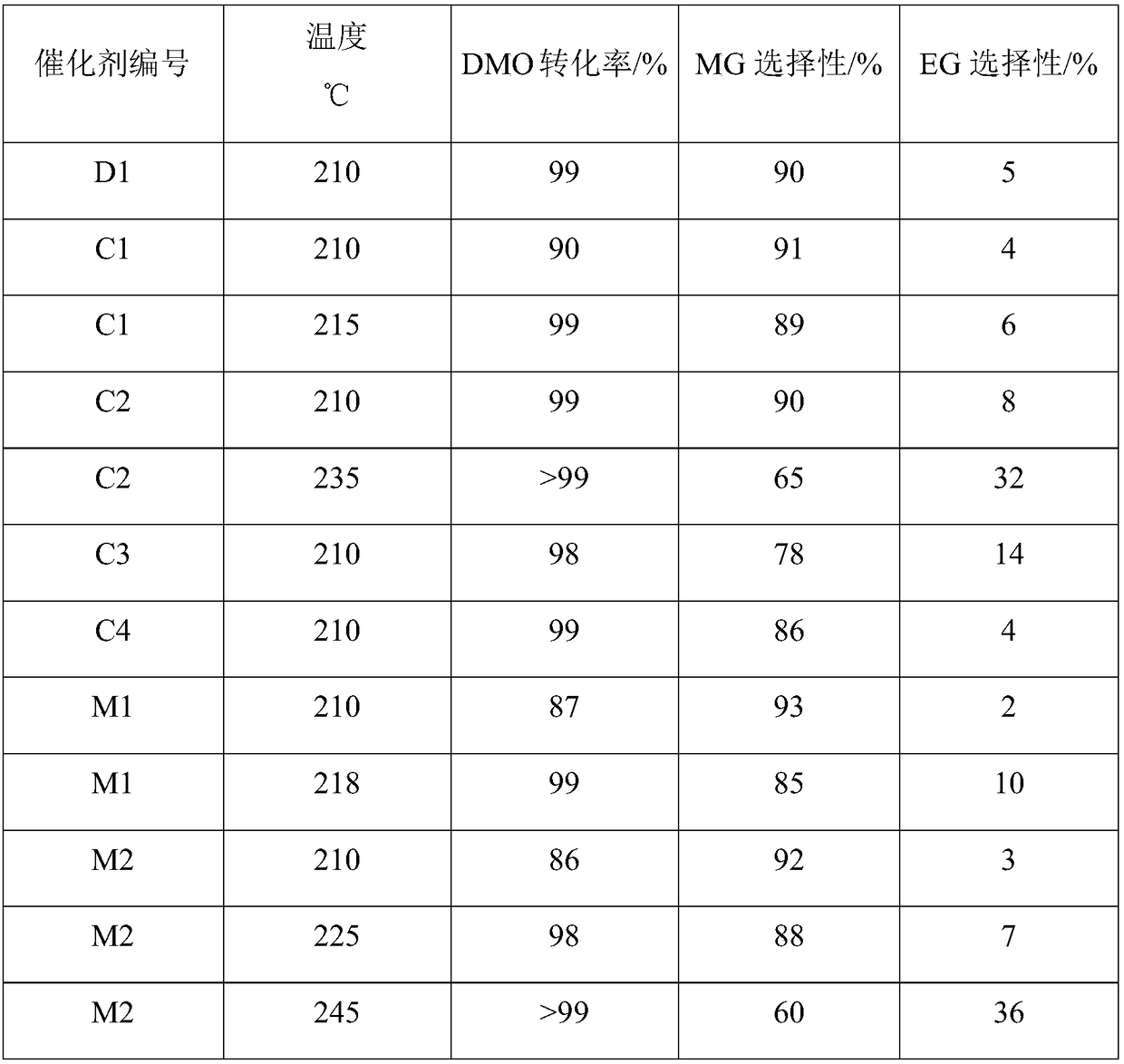

[0030] The above hydrogenation catalyst is used for hydrogenation of dimethyl oxalate to produce methyl glycolate and ethylene glycol. The reduction temperature is 100°C, the reduction pressure is 0....

Embodiment 2

[0034] Weigh 1200g of calcium nitrate tetrahydrate, 550g of white carbon black and 2000g of water and mix evenly. After the above mixture is left to stand for 1 hour, it is dried at 120°C for 8 hours. The dried solid is roasted in a muffle furnace at 650°C for 4 hours to obtain the required carrier. Weigh 180.0g of silver nitrate and dissolve it in 2000g of water to prepare solution R1, then add the above-mentioned carrier for impregnation, filter out the excess mother liquor after standing at room temperature for 2 hours, and then dry at 130°C for 10 hours; the dried solid is in Baking at 500°C for 4 hours. The solid obtained after roasting is compressed into a cylinder by a tablet machine, and the size is 5*5mm. The pressure test strength of the solid catalyst after molding is 130-162 N / cm, and the obtained catalyst number is C2.

[0035] The above-mentioned hydrogenation catalyst is used for the hydrogenation of dimethyl oxalate to produce methyl glycolate and ethylene gl...

Embodiment 3

[0037] Weigh 1400g of calcium nitrate tetrahydrate, 500g of white carbon black and 1900g of water and mix evenly. The above mixture continues to stand for 2 hours and then dried at 135°C for 8 hours. The dried solid is roasted in a muffle furnace at 660°C for 4 hours to obtain the required carrier. Weigh 148.0g of silver nitrate and dissolve it in 1000g of water to prepare solution R1, then add the above carrier for impregnation, let stand at room temperature for 2 hours and then dry at 140°C for 8 hours; the dried solid is calcined at 480°C for 6 hours. Weigh 18g of copper nitrate and dissolve it in 600g of water to prepare solution R2, repeat the impregnation, drying and roasting steps of R1 to form a solid into a cylinder with a size of 5*5mm. The pressure test strength of the solid catalyst after molding is 136-178 N / cm, and the obtained catalyst number is C3.

[0038] The above hydrogenation catalyst is used for hydrogenation of dimethyl oxalate to produce methyl glycola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com