Preparation method of high-pressure seamless steel cylinder

A technology of seamless steel and steel cylinders, applied in the manufacture of container structures, pressure vessels, mechanical equipment, etc., can solve the problems of bottle cavity rust, energy consumption of metal debris, etc., achieve stable heating temperature, reduce production energy consumption, heat fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

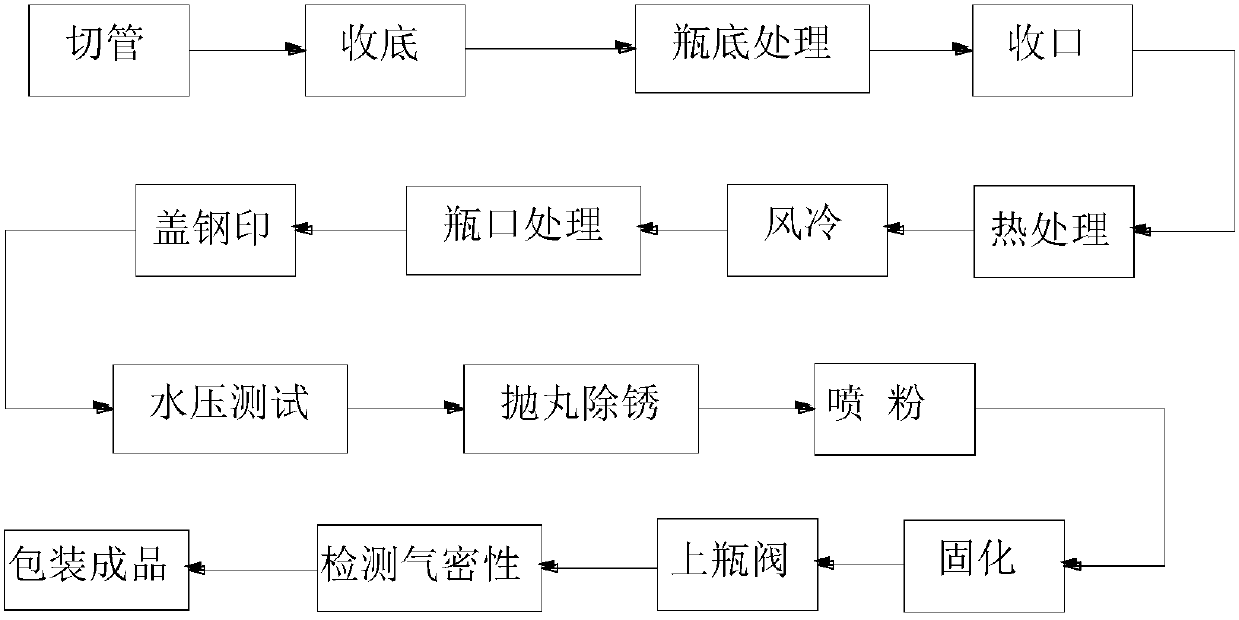

[0028] Embodiment 1: as figure 1 Shown, a kind of preparation method of high-pressure seamless steel cylinder is made up of following production sequence:

[0029] (1) pipe cutting, the seamless steel pipe is cut into several steel cylinder blanks with a length of 1450mm, which is the shortest length that meets the processing needs of the preparation method of the high-pressure seamless steel cylinder, and saves raw materials compared to other lengths;

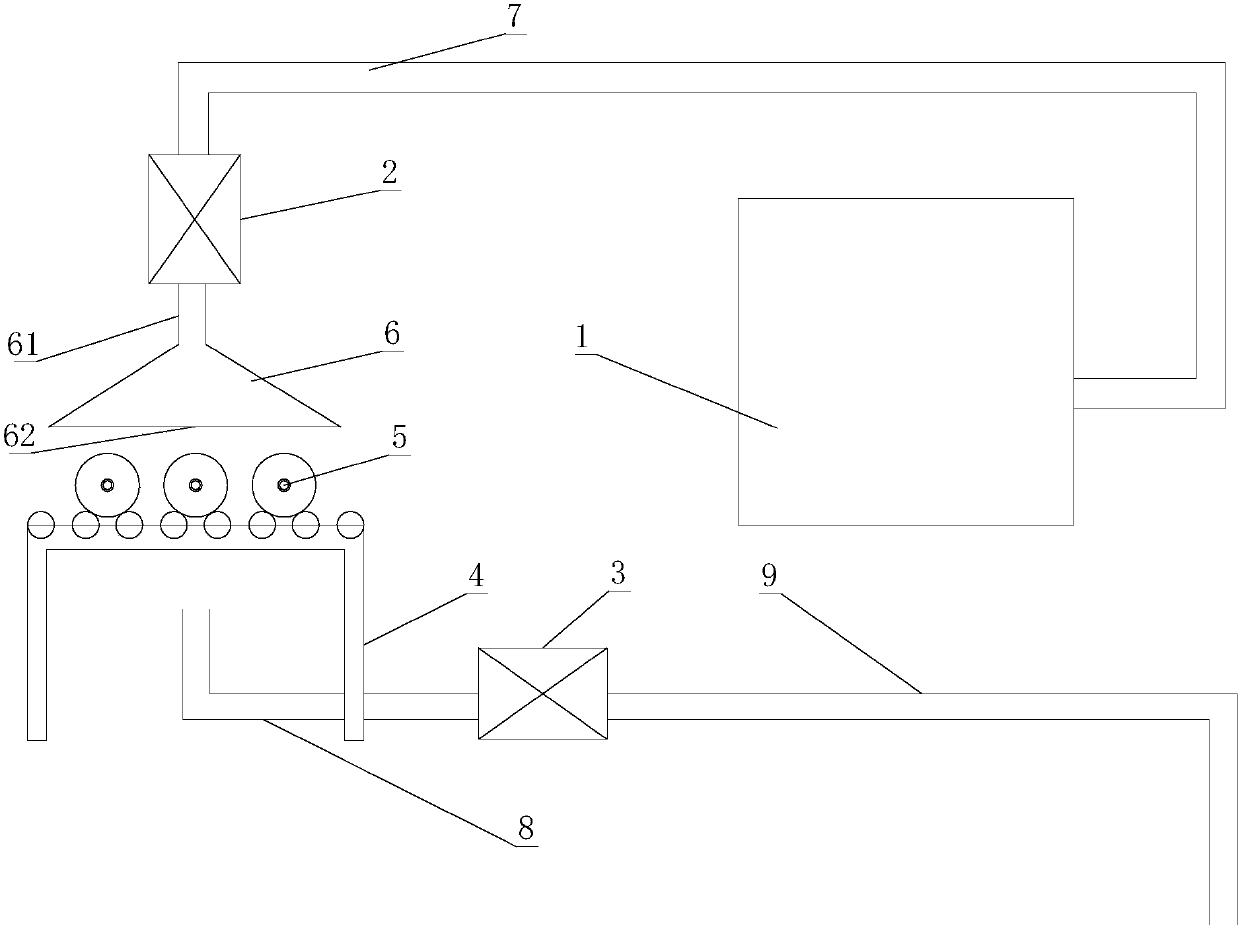

[0030] (2) Bottom closing, the bottoming of the steel cylinder blank after step (1) is cut, and the bottoming is completed by the bottoming device, which includes clamping parts, electromagnetic heating parts and rolling parts, and the electromagnetic heating parts are directly installed The design on the bottom receiving device avoids heat loss during the transfer process; the clamping part fixes one end of the steel cylinder blank, and the electromagnetic heating part electromagnetically heats the other end of the steel cyli...

Embodiment 2

[0045] Embodiment 2: the main steps of the preparation method of the high-pressure seamless steel cylinder that the present embodiment relates to are the same as embodiment 1, and the difference is that the shot blasting liquid described in step (10) contains 3% (percentage by weight) diethanolamine, 3% (weight percent) triethanolamine, 5% (weight percent) oxalic acid, 5% (weight percent) phosphoric acid, 2% (weight percent) zinc dihydrogen phosphonate, 2% (weight percent) benzotriazole and 80 % (percentage by weight) water, because the inner surface is not sprayed with paint, the diethanolamine contained in the shot blasting liquid, triethanolamine, zinc dihydrogen phosphonate, benzotriazole have antirust function, and the oxalic acid contained in the shot blasting liquid 1. Phosphoric acid has the function of rust removal; oxalic acid, as a weak acid, will not corrode steel shots, and the price is relatively cheap; the raw materials contained in shot blasting liquid are simpl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com