An antistatic and heat-resistant soybean fiber blended fabric

A soybean fiber and blended fabric technology, applied in the direction of animal fiber, plant fiber, fiber treatment, etc., can solve the problems of poor moisture and heat resistance of the fiber, easy to generate bacteria, easy to generate static electricity, etc., to achieve good thermal performance, prevent pilling defects, The effect of preventing damage to the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

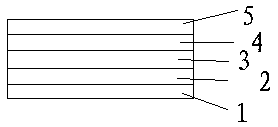

[0035] An antistatic and heat-resistant soybean fiber blended fabric, from the inner layer to the outer layer, consists of a soybean protein fiber-cellulose fiber blended layer, a wool fiber layer, a nano-bamboo charcoal fiber layer, a pineapple leaf fiber layer, and an anti-pilling fiber layer. The pineapple leaf fiber layer is provided with an anti-mosquito bite agent, the wool fiber layer is provided with an antibacterial disinfectant, and the anti-pilling fiber layer is provided with a negative thermal expansion agent. The above composition is prepared according to the following parts by weight: 30% soybean protein Fiber-cellulose fiber layer blended layer, 10 anti-pilling fiber layer, 35 wool fiber layer, 15 nanometer bamboo charcoal fiber layer, 1 anti-mosquito bite agent, 20 pineapple leaf fiber layer, 2 antibacterial disinfectant, 3 negative thermal expansion agent, all In the soybean protein fiber-cellulose fiber blended layer, the weight portion of the soybean protein...

Embodiment 2

[0048] An antistatic and heat-resistant soybean fiber blended fabric, from the inner layer to the outer layer, consists of a soybean protein fiber-cellulose fiber blended layer, a wool fiber layer, a nano-bamboo charcoal fiber layer, a pineapple leaf fiber layer, and an anti-pilling fiber layer. The pineapple leaf fiber layer is provided with an anti-mosquito bite agent, the wool fiber layer is provided with an antibacterial disinfectant, and the anti-pilling fiber layer is provided with a negative thermal expansion agent. The above composition is prepared according to the following parts by weight: 40 soybean protein Fiber-cellulose fiber layer blended layer, 15 anti-pilling fiber layer, 45 wool fiber layer, 20 nanometer bamboo charcoal fiber layer, 3 anti-mosquito bite agent, 30 pineapple leaf fiber layer, 5 antibacterial disinfectant, 6 negative thermal expansion agent, all In the soybean protein fiber-cellulose fiber blended layer, the weight portion of soybean protein fibe...

Embodiment 3

[0050] An antistatic and heat-resistant soybean fiber blended fabric, from the inner layer to the outer layer, consists of a soybean protein fiber-cellulose fiber blended layer, a wool fiber layer, a nano-bamboo charcoal fiber layer, a pineapple leaf fiber layer, and an anti-pilling fiber layer. The pineapple leaf fiber layer is provided with an anti-mosquito bite agent, the wool fiber layer is provided with an antibacterial disinfectant, and the anti-pilling fiber layer is provided with a negative thermal expansion agent. The above composition is prepared according to the following parts by weight: 35% soybean protein Fiber-cellulose fiber layer blended layer, 12 anti-pilling fiber layer, 40 wool fiber layer, 17 nanometer bamboo charcoal fiber layer, 2 anti-mosquito bite agent, 25 pineapple leaf fiber layer, 3 antibacterial disinfectant, 5 negative thermal expansion agent, all In the soybean protein fiber-cellulose fiber blended layer, the weight portion of soybean protein fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com