A method and device for producing kilogram-scale large-diameter graphite oxide/graphene oxide

A kilogram-level, large-scale technology, which is applied in the field of large-diameter graphene oxide preparation, can solve the problems of long reaction time, product repeatability and large-scale production, and many human-operated procedures, so as to reduce the reaction time cycle and strengthen intercalation. Oxidation ability, effect of improving repeat stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

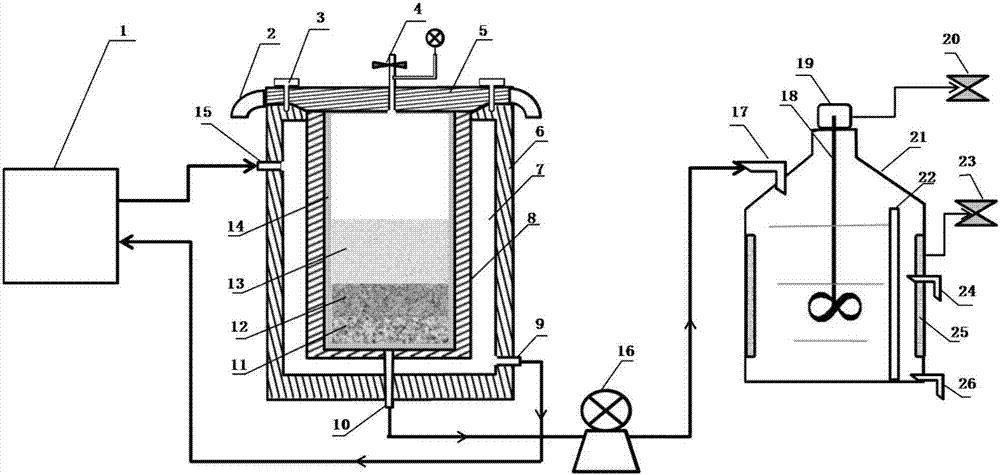

[0040] 0.5kg of 250-mesh natural flake graphite, 2.5kg of potassium permanganate and 25L of concentrated sulfuric acid fully cooled at 2°C are placed in layers in the closed reaction vessel inner wall 8 sprayed with an acid-resistant and anti-corrosion layer 14 in sequence, and fixed The bolt 3 fixes the upper cover 5 of the airtight reaction vessel and the outer wall 6 of the airtight reaction vessel to play a role of airtightness; when the constant temperature control tank 1 is opened, the temperature of the circulating temperature control medium layer 7 is regulated at 3 through the liquid inlet 15 and the liquid outlet 9. °C and maintain the reaction for 2 hours.

[0041] Subsequently, increase the temperature of the constant temperature control tank 1 to 80°C, and after maintaining it for 2 hours, stop heating, cool naturally or cool the reaction vessel to room temperature through the constant temperature control tank 1, and open the safety pressure burst valve 4 to make t...

Embodiment 2

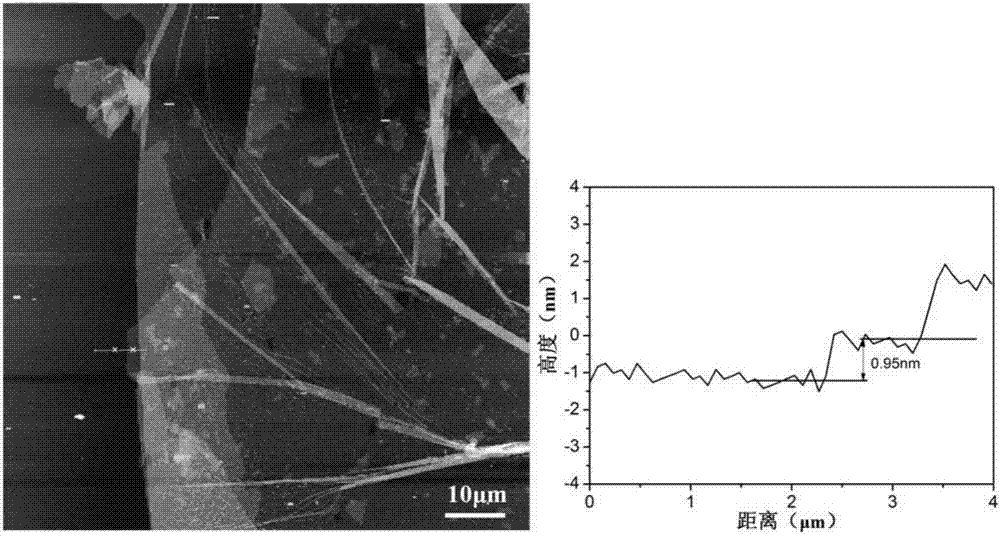

[0044] According to the basic process described in Example 1, 1 kg of 50-mesh expandable graphite, 5 kg of potassium permanganate and 60 L of concentrated sulfuric acid fully cooled at 0 ° C were placed in the reaction vessel in order to maintain it at 1 ° C. React for 2 hours; then, increase the temperature to 70°C for 2 hours, cool and pump it into the liquid storage tank for multiple times of standing, washing, and standing, and obtain graphene oxide slurry through ultrasonic treatment. Gained graphene oxide slurry atomic mechanical microscope analysis picture is as follows image 3 As shown, it is shown that the products are all sheet-like structures with a thickness of 0.95 nm and a sheet diameter of more than 150 μm.

Embodiment 3

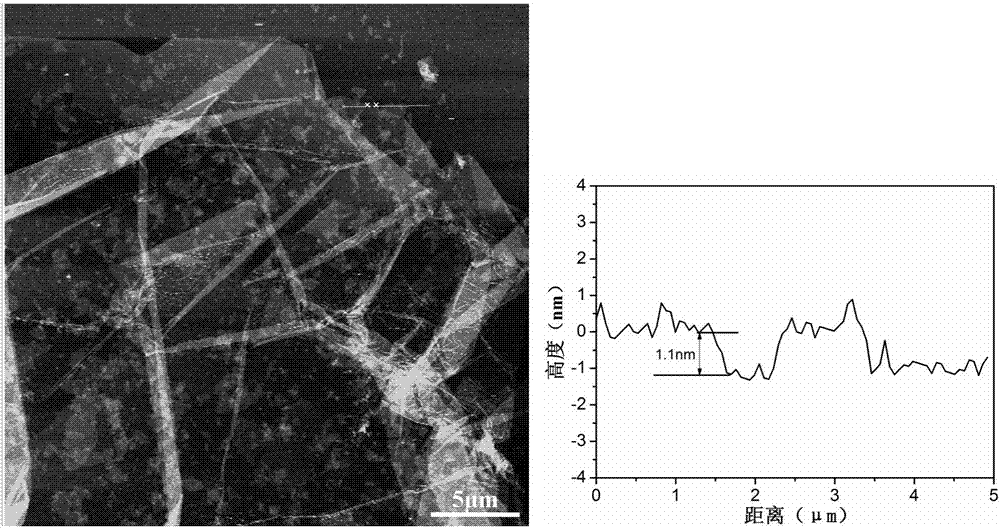

[0046] According to the basic process described in Example 1, 0.5kg of 200-mesh expanded graphite, 2kg of potassium permanganate and 40L of concentrated sulfuric acid fully cooled at 2°C were layered in the reaction vessel in order to maintain it at 5°C. React for 2 hours; then, increase the temperature to 60°C and maintain for 1.5 hours, cool and pump into the liquid storage tank for multiple times of standing, washing, and standing, and obtain graphene oxide slurry through ultrasonic treatment. Gained graphene oxide slurry atomic mechanical microscope analysis picture is as follows Figure 4 As shown, it is shown that the products are all sheet-like structures with a thickness of 1.1 nm and a sheet diameter of more than 70 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com