Preparation method of temperature-resistant iron oxide yellow

An iron oxide yellow, temperature-resistant technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve the problems of pigments containing chlorides, long process lines, etc., to achieve high tinting strength, simple process flow, and less equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

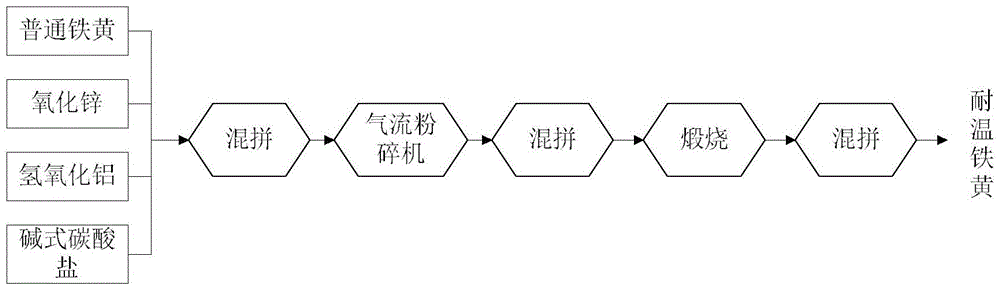

Method used

Image

Examples

Embodiment

[0020] Step 1, commercially available common iron oxide yellow (313) 700kg, zinc oxide 300kg, aluminum hydroxide 30kg and basic carbonate (adding 0.5%, 1%, 2% basic carbonate respectively, with iron yellow quality as the basis) mixed and added to the mixer (double helix conical mixer ZHJ-15W (DSH-15)), mixed for 1 hour, and then the mixture was placed in a jet mill (Huisheng 3R2620) to pulverize evenly. Then mix again in the blender for 1 hour, so that all substances are fully mixed and evenly mixed.

[0021] Step 2, the mixture obtained in step 1 is calcined at 850°C for 2 hours in a pusher kiln, and after cooling, it is placed in a blender and blended for 10-20 minutes to obtain a temperature-resistant zinc iron yellow product. The temperature resistance test of raw materials and products at different temperatures (190°C, 220°C, 250°C, 280°C) obtained the following data:

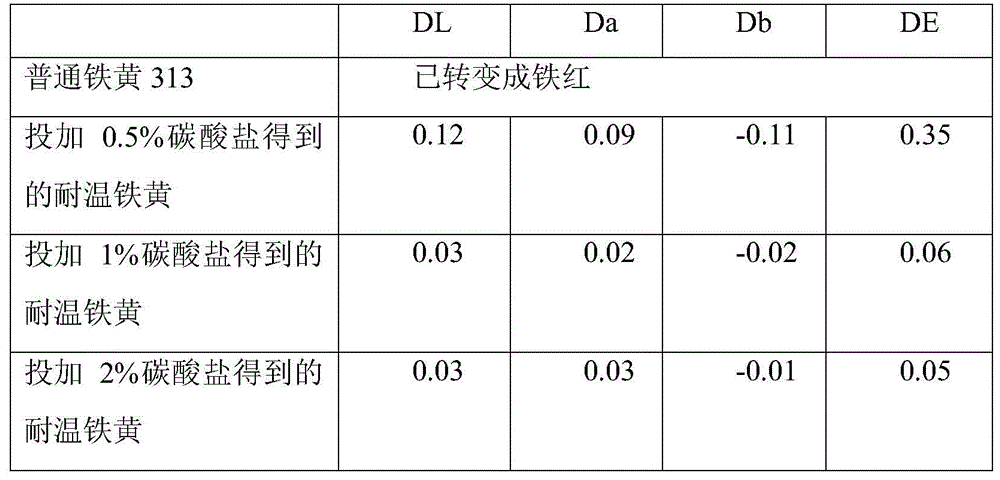

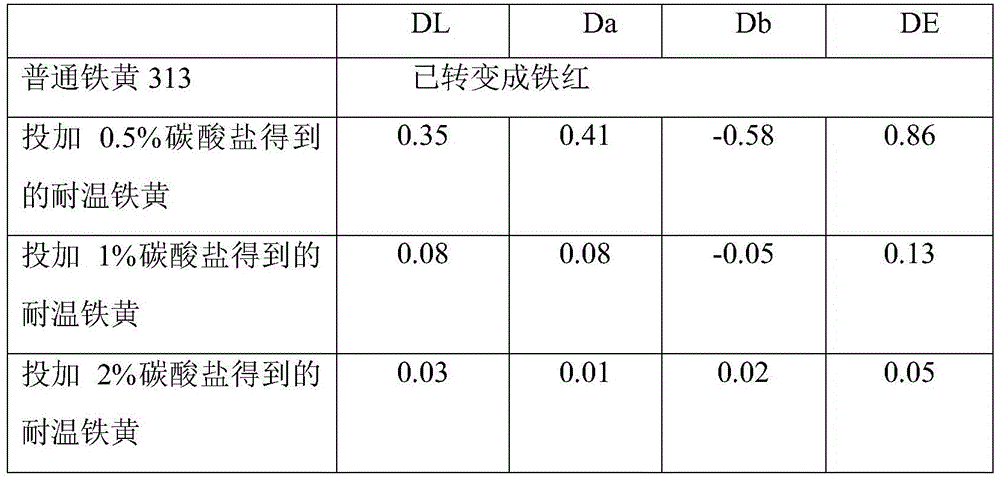

[0022] Table 1190 ℃ temperature resistance performance comparison

[0023]

[0024] It can be seen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com