A Composite Membrane Separation Method Applicable to Sewage Desalination and Reuse

A separation method and composite membrane technology, applied in separation methods, dispersed particle separation, permeation/dialysis water/sewage treatment, etc., can solve the problem of increasing the selective permeability of cations and anions, unable to solve the damage of particle pollutants, and ion exchange membranes High cost and other issues, to achieve the effect of prolonging the membrane cleaning cycle, reducing energy consumption, and improving desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

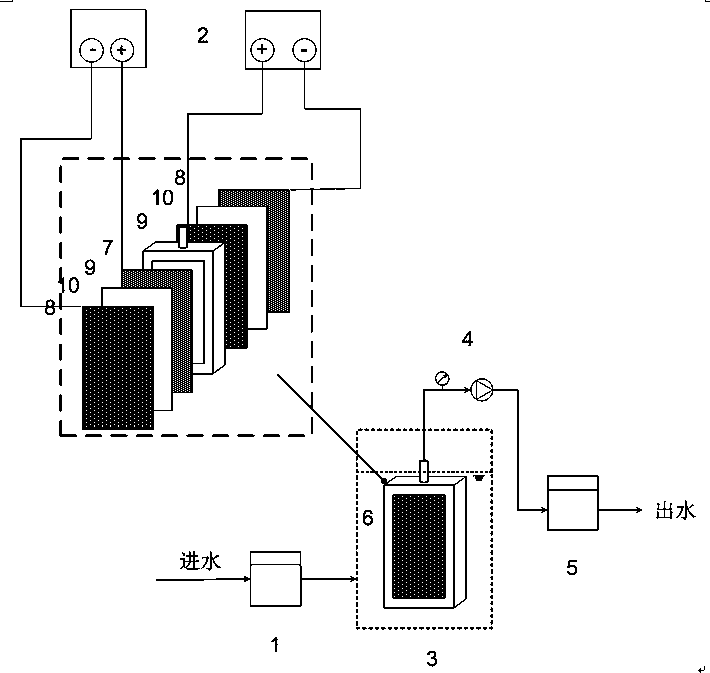

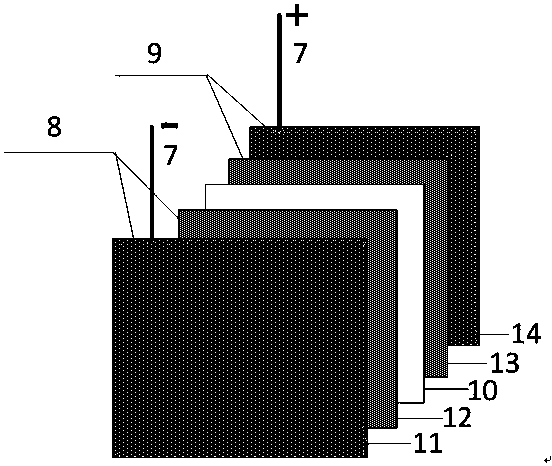

[0027] use figure 1 In the process device shown in , the water inlet system 1 is composed of an inlet pool and an inlet water flow regulating device, and the brackish water mainly composed of NaCl that has been pretreated and meets the process requirements is connected to the inlet pool, and the salt content of the inlet water is 1200 mg / L (calculated as TDS), adjust the influent flow, and control the flux to 10 L / m 2 h. The water outlet of the water inlet tank is connected to the membrane reactor through a pipeline, and the outlet water of the water inlet tank enters the membrane reactor. The membrane reactor is composed of a reaction tank, a composite membrane module 6 and a stirring system. figure 2The composite membrane module shown in , in which the anode composite membrane is bonded by titanium mesh and carbon cloth through PVDF, the cathode composite membrane is bonded by stainless steel mesh and carbon cloth through PVDF, and the separation layer is non-woven fabric...

Embodiment 2

[0029] use figure 1 The process device shown in , the water inlet system 1 is composed of the water inlet tank and the water inlet flow adjustment device, and the biologically treated effluent of the cold rolling wastewater that has been pretreated and meets the process requirements is connected to the water inlet tank, and the salt content of the water inlet is 1000 mg / L (calculated as TDS), the concentration of suspended solids is 50 mg / L, adjust the influent flow, and the control flux is 40 L / m 2 h. The water outlet of the water inlet tank is connected to the membrane reactor through a pipeline, and the outlet water of the water inlet tank enters the membrane reactor. The membrane reactor is composed of a reaction tank, a composite membrane module 6 and a stirring system. figure 2 The composite membrane module shown in , in which both the anode composite membrane and the cathode composite membrane are bonded by titanium mesh and carbon cloth through PAN, and the separat...

Embodiment 3

[0031] use figure 1 The process device shown in , the water inlet system 1 is composed of the water inlet tank and the water inlet flow adjustment device, and the industrial wastewater mainly composed of nitrates that has been pretreated and met the process requirements is connected to the water inlet tank, and the water contains salt The amount is 900 mg / L (calculated as TDS), adjust the influent flow, and control the flux to 10 L / m 2 h. The water outlet of the water inlet tank is connected to the membrane reactor through a pipeline, and the outlet water of the water inlet tank enters the membrane reactor. The membrane reactor is composed of a reaction tank, a composite membrane module 6 and a stirring system. figure 2 The composite membrane assembly shown in , wherein both the anode composite membrane and the cathode composite membrane are composed of titanium mesh and carbon nanotubes, the separation layer is nylon mesh, and the cathode composite membrane assembly is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com