Method for reducing emission of ammonia methane gas during sewage sludge composting

A technology of sewage sludge and methane gas, which is applied in the field of agricultural composting to achieve simple operation, good environmental and economic benefits, and improve the quality of composting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

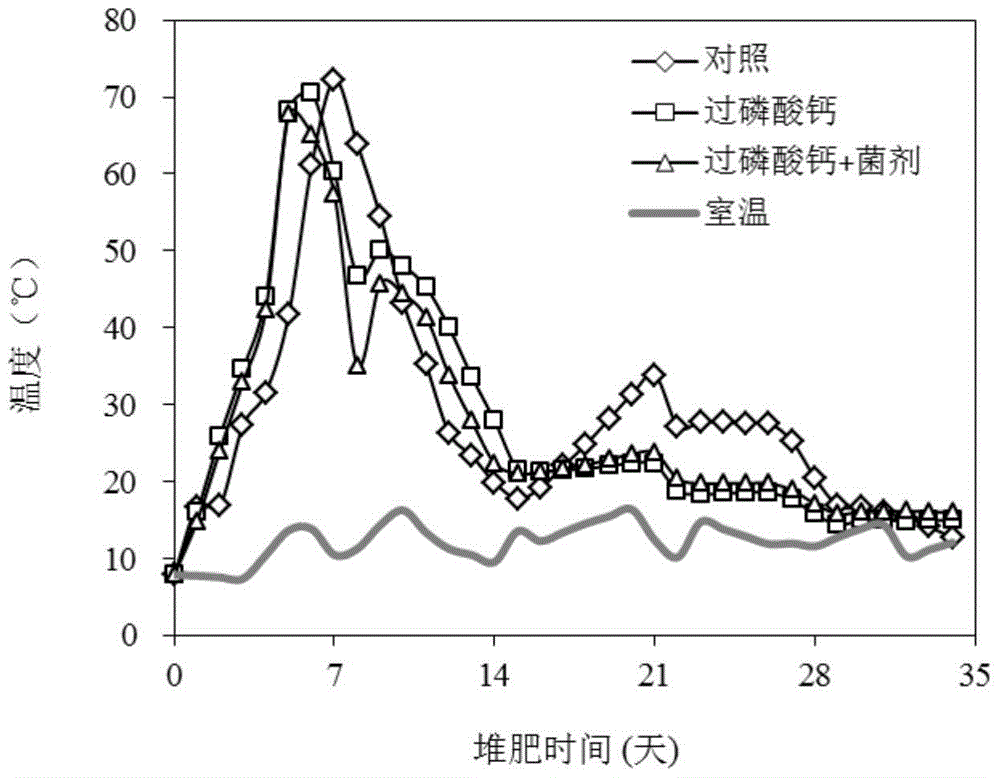

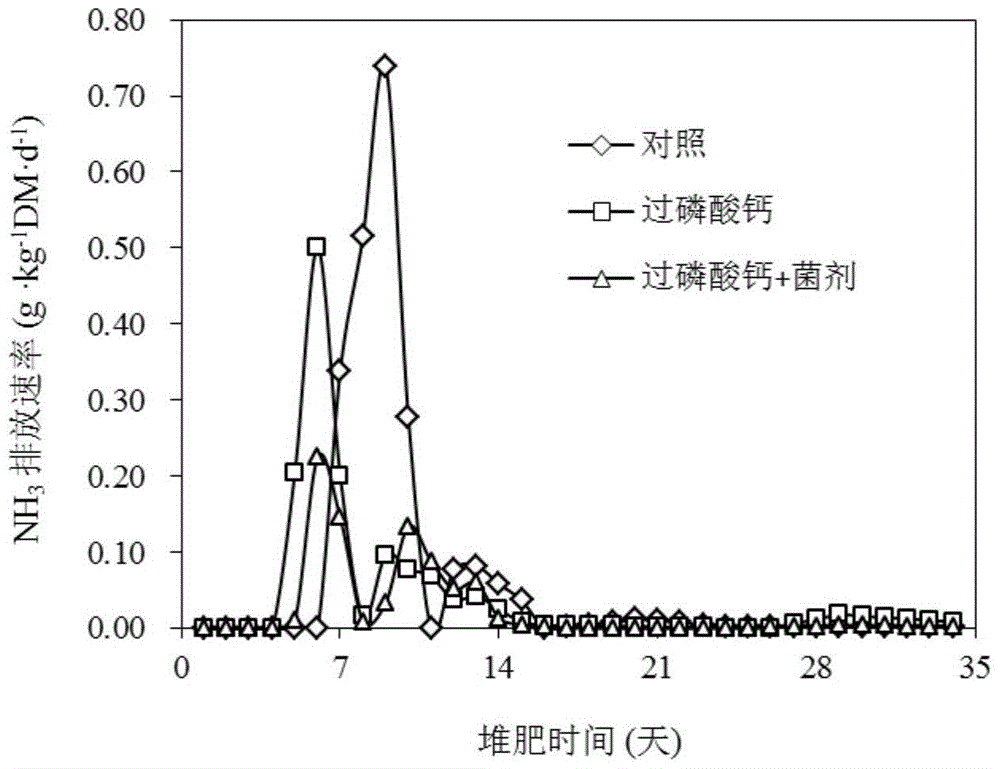

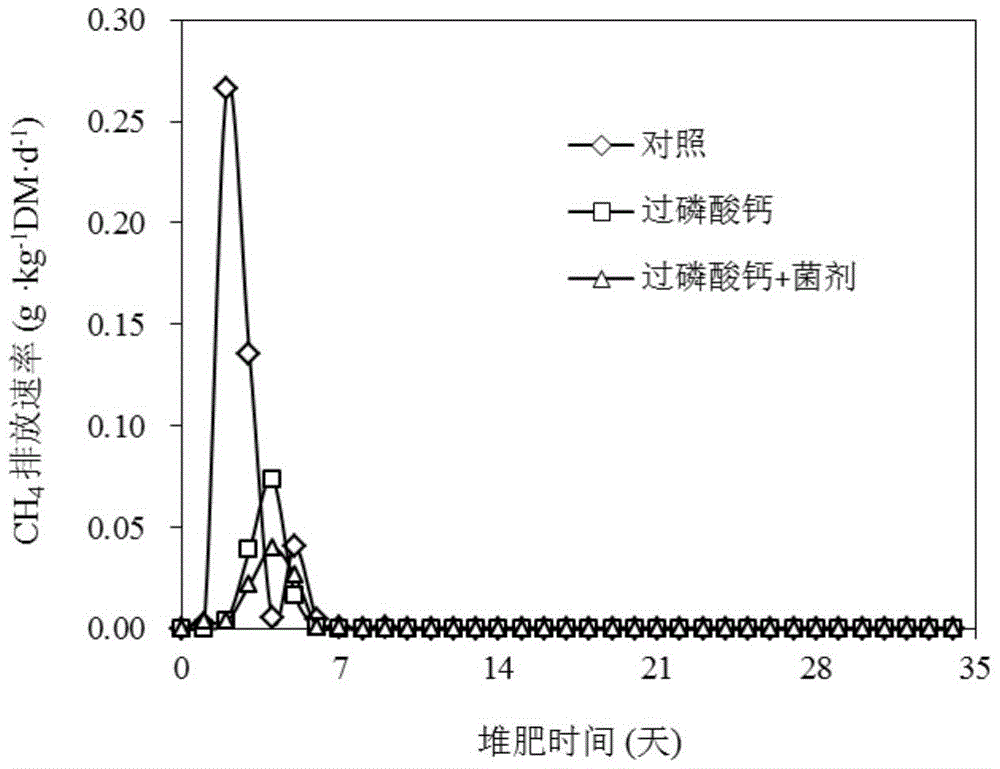

[0024] The sludge used in the test was taken from the dewatered sludge without anaerobic digestion in the domestic sewage treatment plant (Xiaojiahe sewage treatment plant, Beijing), and the corn stalks were taken from the Shangzhuang Experimental Station of China Agricultural University. . Superphosphate was purchased from the market, and the bacterial agent was obtained from Beijing Wotu Tiandi Biotechnology Co., Ltd. Dewatered sludge and corn stalks were mixed evenly at a ratio of 85:15 by wet weight. Three treatments were set up in the test. In addition to the control, superphosphate was added in treatment 2, and the amount of superphosphate added was 3% of the total wet weight of compost raw materials. In treatment 3, superphosphate and bacterial agents were added at the same time. The addition amount is the same as that of treatment 2, and the addition amount of the composite functional bacterial agent is 0.1% of the wet weight of the compost material. When preparing c...

Embodiment 2

[0037] The difference from Example 1 is that the dewatered sludge and corn stalks are evenly mixed according to the wet weight ratio of 85:20. There were 3 treatments in the test. In addition to the control, calcium superphosphate was added in treatment 2. The amount of superphosphate added was 4% of the total wet weight of compost raw materials. In treatment 3, calcium superphosphate and bacterial agents were added at the same time. The addition amount is the same as that of treatment 2, and the addition amount of the composite functional bacterial agent is 0.2% of the wet weight of the compost material. When preparing compost raw materials, superphosphate and bacterial agents are evenly sprinkled on the mixture of sludge and corn stalks, and mixed several times to fully mix with the materials.

Embodiment 3

[0039] The difference from Example 1 is that the dewatered sludge and corn stalks are evenly mixed according to the wet weight ratio of 85:10. Three treatments were set up in the experiment. In addition to the control, superphosphate was added in treatment 2, and the amount of superphosphate added was 2% of the total wet weight of compost raw materials. In treatment 3, superphosphate and bacterial agents were added at the same time. The addition amount is the same as that of treatment 2, and the addition amount of the composite functional bacterial agent is 0.05% of the wet weight of the compost material. When preparing compost raw materials, superphosphate and bacterial agents are evenly sprinkled on the mixture of sludge and corn stalks, and mixed several times to fully mix with the materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com