Modified starch composition for soil water retention and preparation method thereof

A composition and starch technology, applied in fertilizer mixtures, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of high cost, unfavorable crop growth, slow degradation, etc., and achieve simple operation, easy control, good water absorption and water retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

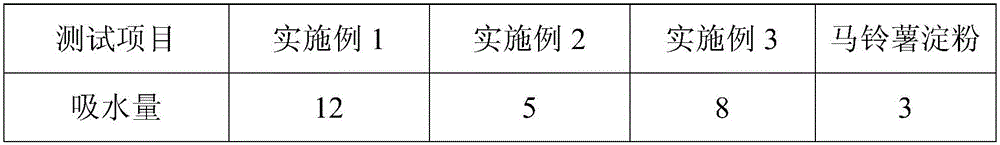

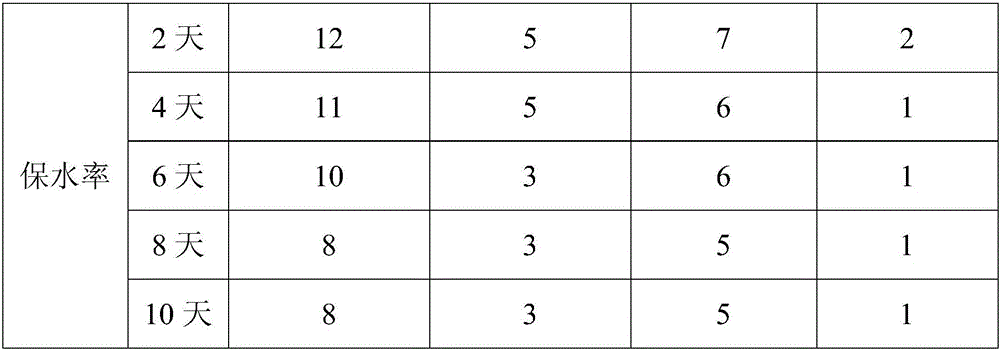

Examples

Embodiment 1

[0028] The modified starch composition for soil water retention in this embodiment is prepared by the following method, and the specific operation steps are:

[0029] 1) taking sodium trimetaphosphate and chloroacetic acid and adding them into ethanol aqueous solution with a mass concentration of 58%, mixing uniformly to obtain a mixed solution, taking potato starch and adding them to the mixed solution to obtain a mixed material;

[0030] 2) Heat the mixed material prepared in step 1) to 45° C., then add a sodium hydroxide solution with a mass concentration of 7% to adjust the pH of the mixed material to 11.2, and react for 10 hours to obtain the reaction material 1;

[0031] 3) Add sodium polyacrylate and guar gum to the reaction material 1 prepared in step 2), mix well, then add water, stir and react for 80 minutes to obtain reaction material 2;

[0032] 4) Pump the reaction material 2 prepared in step 3) into the drum dryer for drying and gelatinization. Control the steam ...

Embodiment 2

[0035] The modified starch composition for soil water retention in this embodiment is prepared by the following method, and the specific operation steps are:

[0036] 1) Take epichlorohydrin and sodium chloroacetate and add them to ethanol aqueous solution with a mass concentration of 55%, mix well to obtain a mixed solution, take waxy cornstarch and add them to the mixed solution to obtain a mixed material;

[0037] 2) Heat the mixed material prepared in step 1) to 40° C., then add a sodium hydroxide solution with a mass concentration of 5% to adjust the pH of the mixed material to 11.1, and react for 12 hours to obtain the reaction material 1;

[0038] 3) Add sodium polyacrylate and guar gum to the reaction material 1 prepared in step 2), mix well, then add water, stir and react for 6 minutes to obtain reaction material 2;

[0039] 4) Pump the reaction material 2 prepared in step 3) into the drum dryer for drying and gelatinization. Control the steam pressure of the dryer to...

Embodiment 3

[0042] The modified starch composition for soil water retention in this embodiment is prepared by the following method, and the specific operation steps are:

[0043] 1) adding sodium tripolyphosphate and propylene oxide into an ethanol aqueous solution with a mass concentration of 60%, and mixing uniformly to obtain a mixed solution, adding potato starch to the mixed solution to obtain a mixed material;

[0044] 2) Heat the mixed material prepared in step 1) to 50° C., then add a sodium hydroxide solution with a mass concentration of 8% to adjust the pH of the mixed material to 11.35, and react for 8 hours to obtain the reaction material 1;

[0045] 3) Add sodium polyacrylate and guar gum to the reaction material 1 prepared in step 2), mix well, then add water, stir and react for 160 minutes to obtain reaction material 2;

[0046]4) Pump the reaction material 2 prepared in step 3) into the drum dryer for drying and gelatinization, control the steam pressure of the dryer to 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com