Strain producing pullulan, application thereof and pullulan production method

A pullulan polysaccharide and seed technology, applied in the field of microorganisms, can solve the problems of low sugar conversion rate, slow industrialization progress, low yield, etc., and achieve the effects of increasing sugar conversion rate, increasing pullulan output, and improving the quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

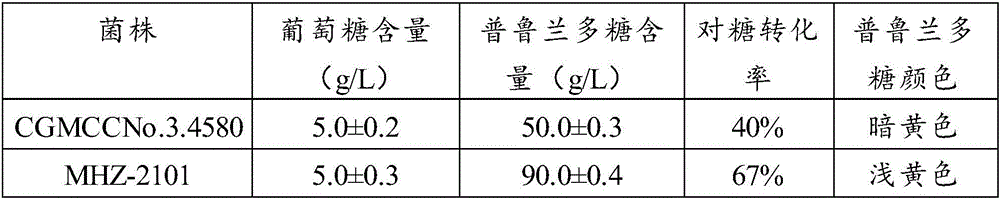

[0039] Embodiment 1: the screening of Aureobasidium pullulans MHZ-2101 belonging to the present invention

[0040] Inoculate the starting strain Aureobasidium pullulans CGMCCNo.3.4580 into solid PDA medium, culture at 28°C for 3 days, add 0.9% sterile saline, and shake fully to obtain a bacterial suspension, and calculate the concentration of the spore suspension by a hemocytometer. Normal saline diluted to 10 6 NTG / mL, the final concentration of 0.5mol / LNTG was treated for 2 hours, washed with normal saline for 3 times, and finally diluted to 10 with normal saline 5 1 / mL, spread 100 μL on a PDA plate, incubate at 28°C in the dark for 7 days, pick a single colony with normal morphology, whitish color, and the largest colony diameter, and name it MHZ-2101.

[0041] The formula of PDA medium is as follows: Peel 200g potatoes, cut into cubes, cook in boiling water for 15min, filter through eight layers of gauze, add 20g of glucose to the filtrate, distill water to 1L, pack in tr...

Embodiment 2

[0043] Embodiment 2: The production method of pullulan polysaccharide according to the present invention and the comparison experiment of pullulan polysaccharide fermentation

[0044] 1. Fermentation method

[0045] Inoculate Aureobasidium pullulans MHZ-2101 into solid PDA medium, culture at 28°C for 3 days, pick a large loop with an inoculation loop and inoculate it into the seed medium, culture at 28°C, 150rpm reciprocating shaker for 20hrs, 1:10 rotation Received the fermentation medium, cultured on a reciprocating shaker at 28° C. for 72 hours at 180 rpm, and measured the content of glucose and pullulan.

[0046] Seed medium: 40g / L glucose, 2.8g / L yeast powder, 6.5g / L potassium dihydrogen phosphate, 0.3g / L magnesium sulfate.

[0047] Fermentation medium: 120g / L glucose, 10g / L yeast powder, 130g / L potassium dihydrogen phosphate, 10g / L magnesium sulfate, 15g / L ammonium sulfate, sodium hydroxide to adjust the pH value to 6.5.

[0048] Glucose content detection: the fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com