Gear precision measurement and evaluation method

A precision measurement and gear technology, applied in the direction of measuring devices, mechanical measuring devices, components with teeth, etc., can solve the problems of gear errors that cannot be fully expressed, online full inspection and systematic management, and low efficiency, and achieve intuitive The visualization is simple and easy to understand, the investment in professional instruments is reduced, and the data information is comprehensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

[0033] The invention provides a method for measuring and evaluating gear accuracy, comprising the following steps:

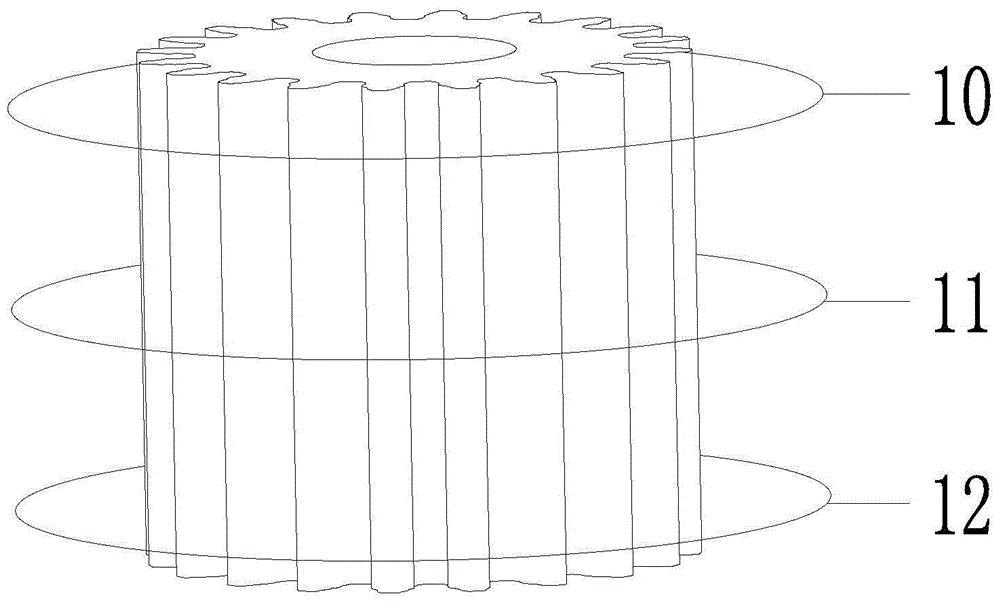

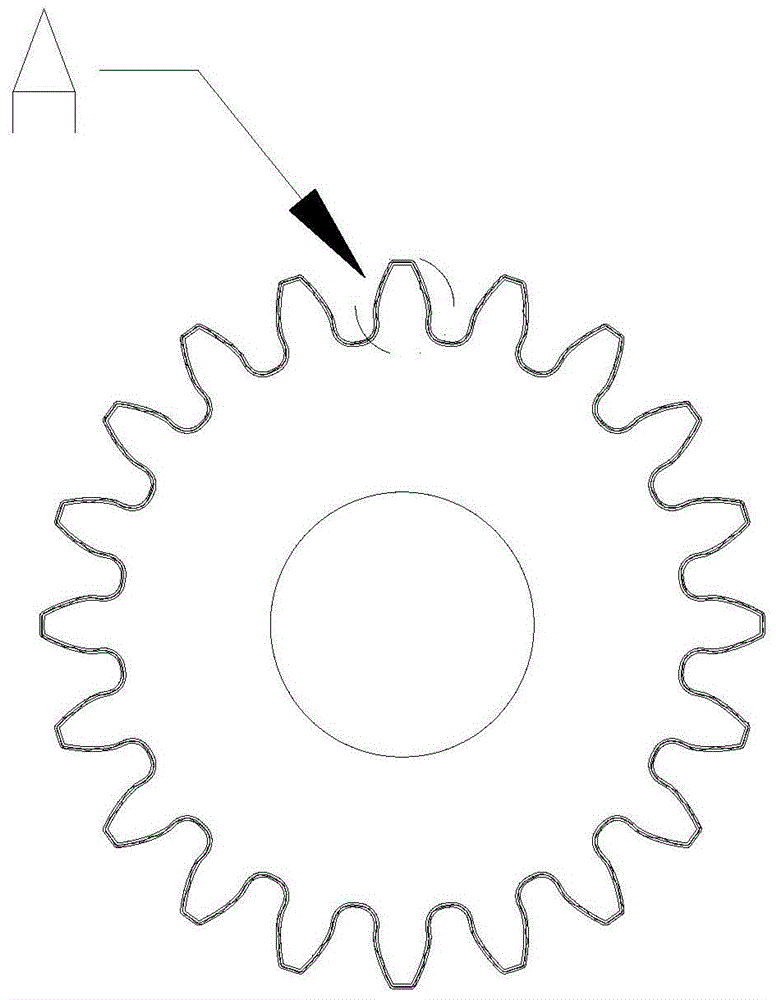

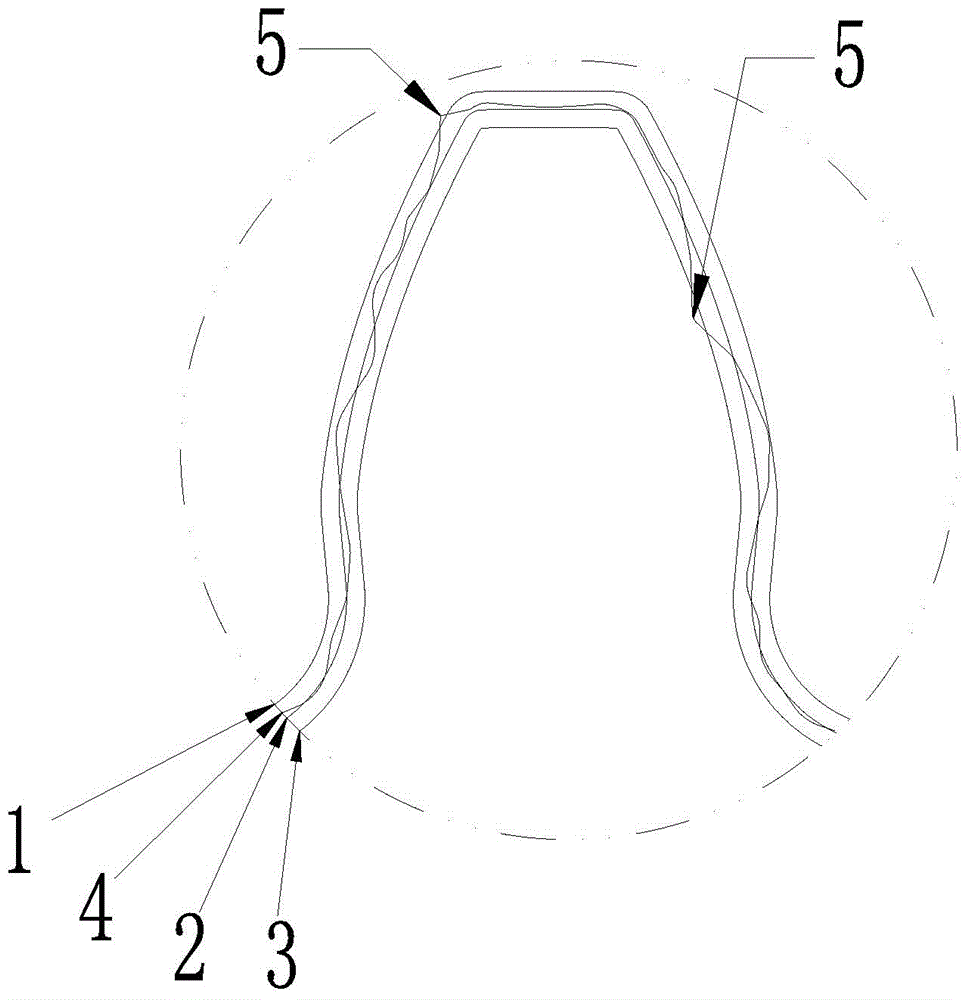

[0034] a) Scan the gear to be tested, and establish the actual model of the gear to be tested through the scanned data; among them, the gear to be tested can be placed on a measuring instrument with the function of circumferential line profile and surface profile to obtain line profile and surface profile data, Or use optical, ray, electromagnetic, electron beam and other measuring and scanning equipment with three-dimensional digital imaging capabilities to obtain real and usable holographic data, such as CT scanning measuring instruments and scanning electron m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com