Optical waveguide, manufacturing method thereof, and method for reducing scattering loss of side wall of V-III semiconductor waveguide

A III-V, manufacturing method technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of restricting the resolution of single-chip integrated optical gyro, large refractive index difference, large scattering loss, and reduced yield, etc., to achieve high Sensitivity single-chip integrated optical gyroscope, overcome loss limitation, and reduce the effect of scattering loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The fabrication process of the low scattering loss waveguide is as follows:

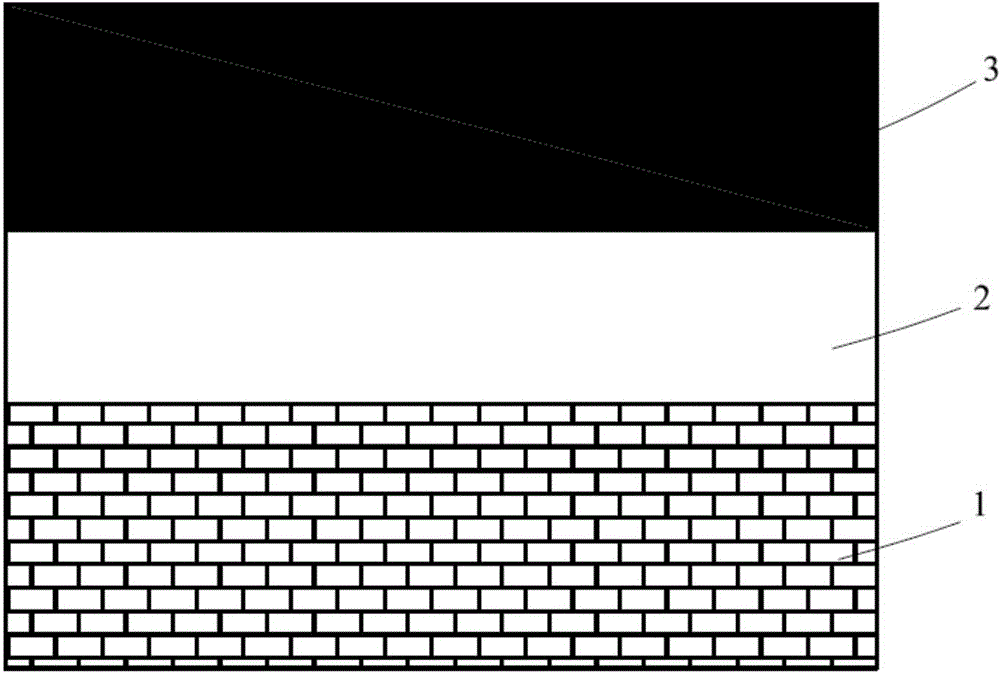

[0030] 1), reference Figure 1a As shown, the lower cladding layer 1, the core layer 2, and the upper cladding layer 3 are sequentially grown on the InP base material by MOCVD (or III-V semiconductor material growth methods such as MBE and HVPE), and the material of the lower cladding layer 1 is InP , the core layer 2 is a III-V semiconductor containing Al, its material is preferably InAlGaAs, and the material of the upper cladding layer is InP (or InGaAsP).

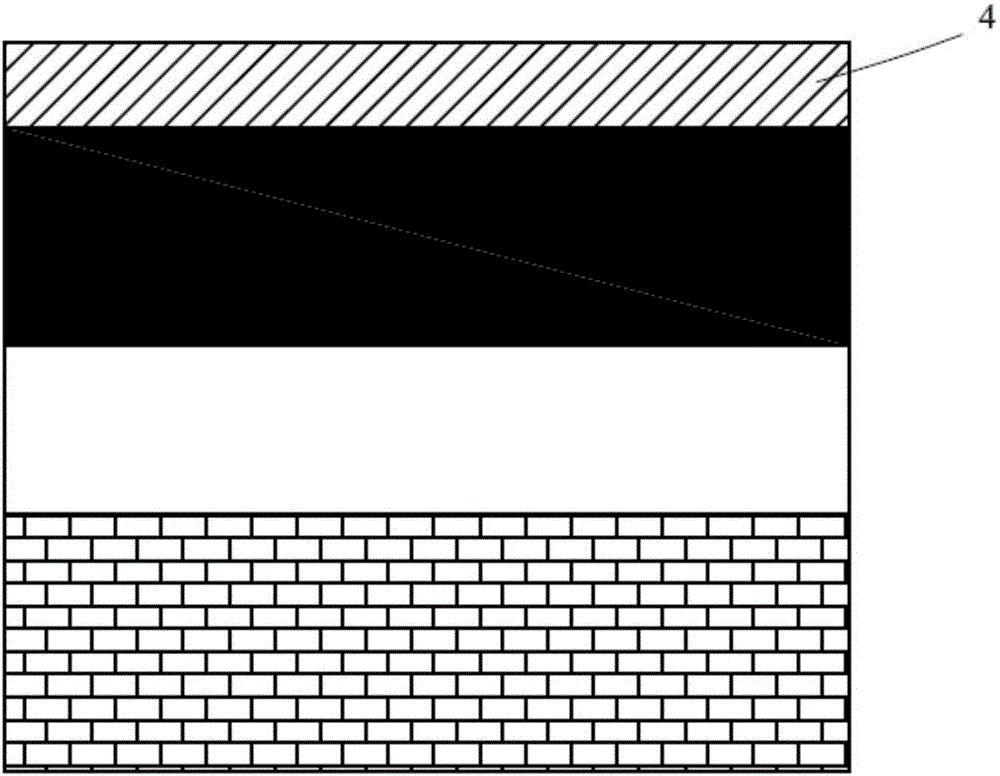

[0031] 2), reference Figure 1b As shown, a photoresist 4 is formed on the surface of the upper cladding layer by using a coater.

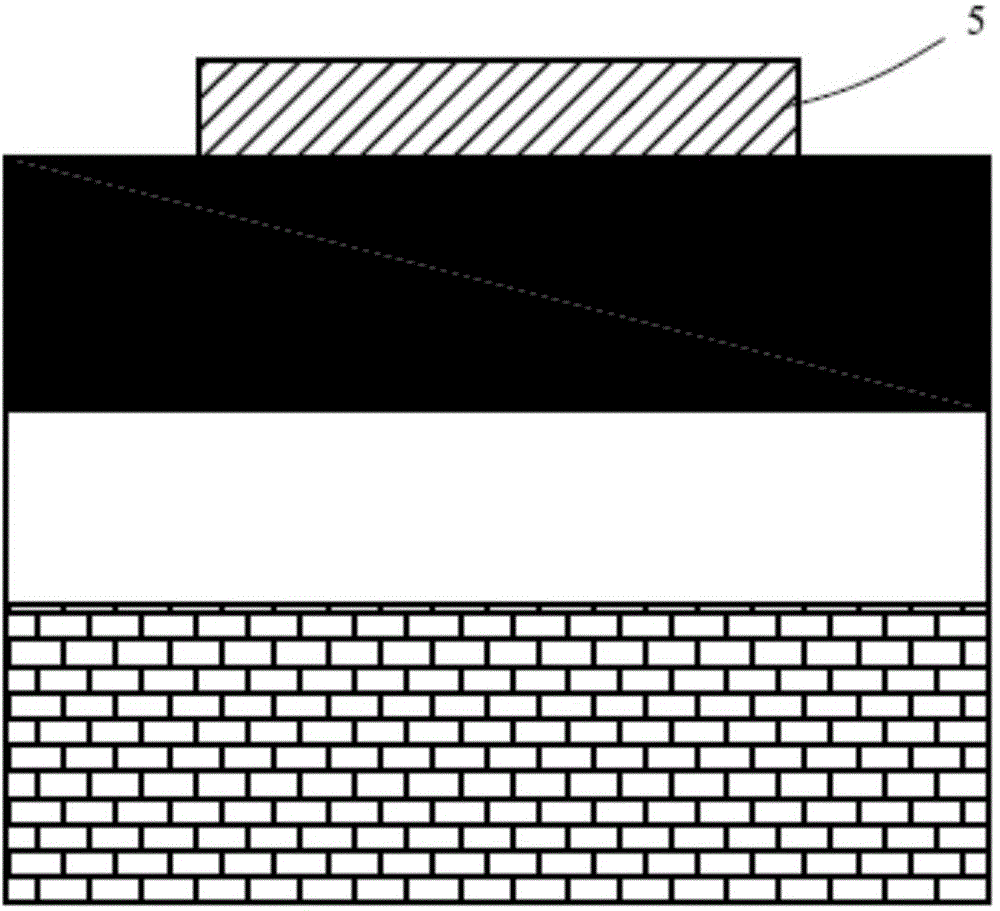

[0032] 3), reference Figure 1c As shown, a pattern mask 5 is obtained by photolithography.

[0033] 4), reference Figure 1d As shown, etching is carried out through the pattern mask 5 until the upper surface of the core layer 2 is exposed.

[0034] 5), reference Figure 1e As shown, the exposed part...

Embodiment 2

[0036] In step 4) of embodiment 1, it is also possible to etch through a pattern mask until the upper surface of the lower cladding layer is exposed, see Figure 2a As shown, aluminum oxidation is then performed on the exposed ends of the core layer to obtain an optical waveguide with smooth sidewalls, see Figure 2b shown.

Embodiment 3

[0038] ginseng image 3 As shown, the optical waveguide can also be a double-groove type, the upper cladding layer is photolithographically formed with two grooves 7, and the two grooves extend to the upper surface of the core layer, and the core layer at the bottom of the groove 7 is aluminum Oxidation can form smooth sidewalls between the oxidized core and the unoxidized core. Its preparation method is the same as that of Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com