Composite station and method of drilling and fixing for the continuous production of a conductive backsheet with an integrated encapsulating and dielectric layer, for photovoltaic panels of the back-contact type

一种集成封装、导电背板的技术,应用在光伏发电、化学仪器和方法、分层产品等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

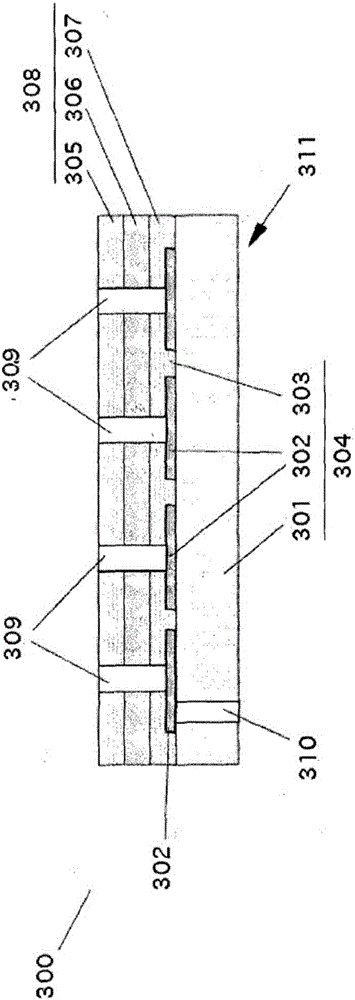

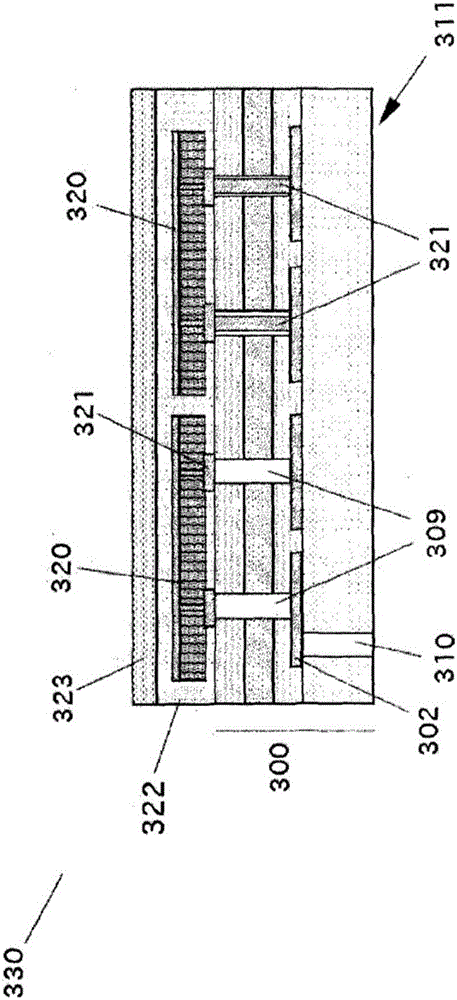

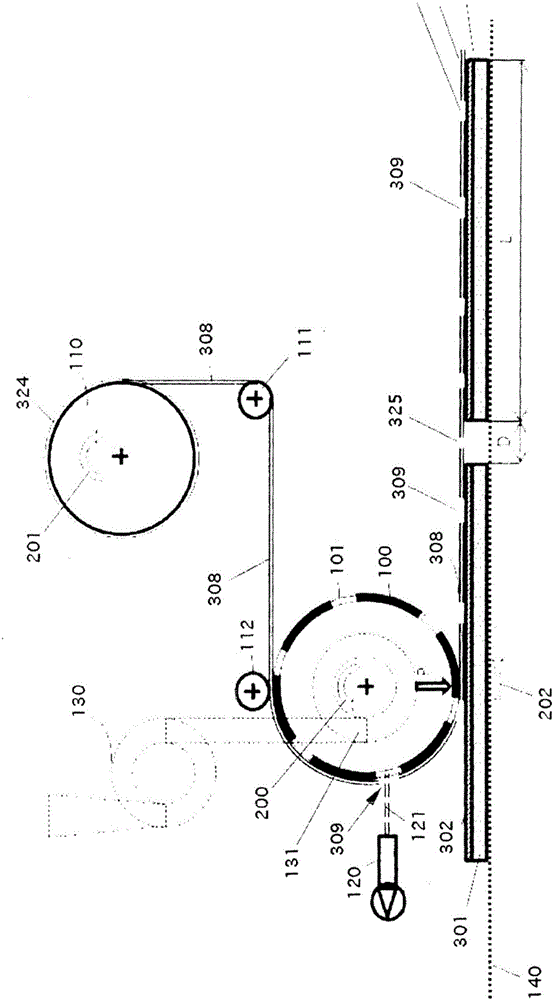

[0037] The present invention describes a composite station and method for centralizing and optimizing the production cycle of conductive backsheets with integrated encapsulation and dielectric layers, intended for assembling back-contact photovoltaic panels. More specifically, there is provided a station (10) of complex type, which is automated and integrates a plurality of operations performed in cycle sequence for the purpose of simultaneous manufacturing, which has high repeatability and low cost, provides There is a specific type of conductive backplane (300) with integrated encapsulation and dielectric layers, which is commonly referred to as BCBS, see table of prior art (Fig. 1a); Intended for use in the construction of photovoltaic panels (330) with a back contact structure, see table of prior art (Fig. 1b). It was found that the conductive backplane is of the type described in ITTV2012A000211 (Baccini et al.) and in turn comprises a semi-finished element called stack (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com