Naked barley drink (naked barley soup) and production method thereof

A production method and a technology of raw wheat, applied in the field of beverages, can solve the problems of not being able to be widely used and the number of users is small, and achieve the effects of diffuse aroma, reasonable composition and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

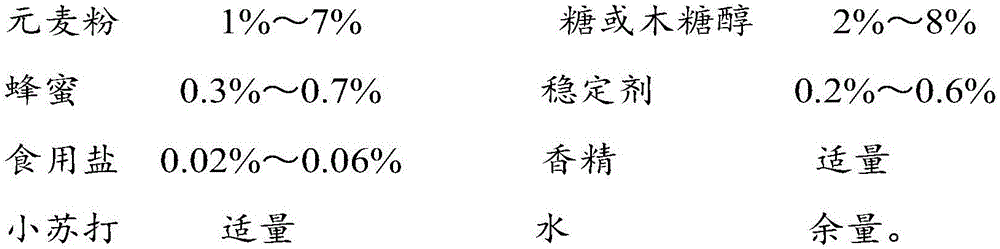

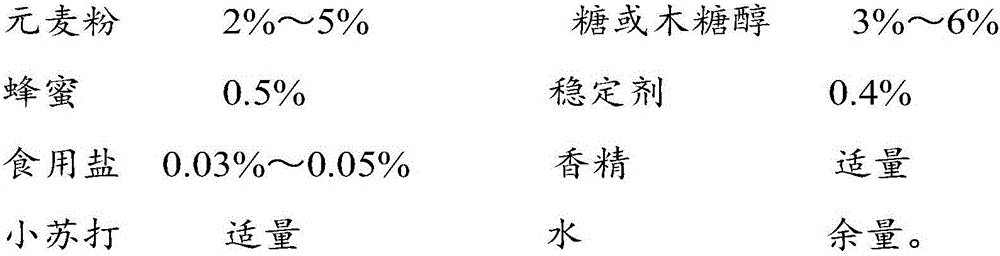

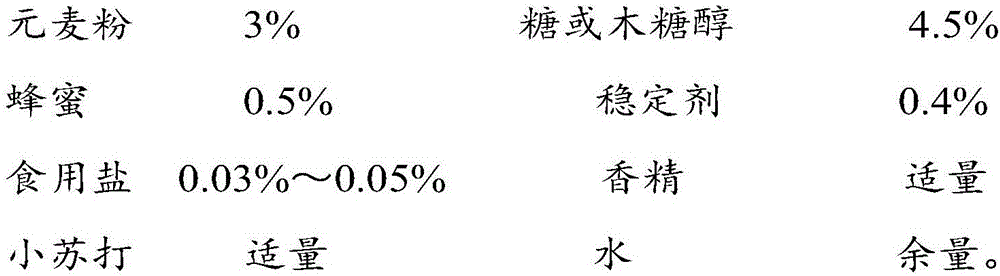

Method used

Image

Examples

Embodiment 1

[0028] A kind of Yuanmai beverage, the production process is as follows:

[0029] 1. Yuan wheat flour pretreatment: 20kg yuan wheat flour is sieved with 80 mesh screen, dissolved in demineralized water according to the ratio of 1:10, heated to 89°C, and kept for 20 minutes, then passed through a colloid mill for one time, and set aside;

[0030] 2. Dry mix 4kg of microcrystalline cellulose, 60kg of sugar and 5kg of honey evenly, stir and add to hot water at 87°C, and continue to stir and dissolve for 25 minutes until no particles are visible to the naked eye;

[0031] 3. Slowly add the pretreated barley pulp to the colloid solution in step 2 under stirring, and continue stirring until the solution is evenly mixed;

[0032] 4. After replenishing water and set the volume to nearly 1000kg, heat to about 65°C for vacuum degassing;

[0033] 5. 65~75℃, 15~18Mpa, homogeneous;

[0034] 6. Add 0.1kg of flavors and fragrances, 0.5kg of edible salt and 0.5kg of baking soda, adjust the ...

Embodiment 2

[0038] A kind of Yuanmai beverage, the production process is as follows:

[0039] 1. Pretreatment of wheat flour: 70kg of wheat flour is sieved with an 80-mesh sieve, dissolved in demineralized water at a ratio of 1:7, heated to 90°C, and kept warm for 22 minutes, then passed through a colloid mill once, and set aside;

[0040] 2. Dry mix 6kg of sucrose esters, 20kg of xylitol and 7kg of honey evenly, stir and add to hot water at 89°C, and continue to stir and dissolve for 30 minutes until no particles are visible to the naked eye;

[0041] 3. Slowly add the pretreated barley pulp to the colloid solution in step 2 under stirring, and continue stirring until the solution is evenly mixed;

[0042] 4. After replenishing water and set the volume to nearly 1000kg, heat to about 65°C for vacuum degassing;

[0043] 5. 65~75℃, 15~18Mpa, homogeneous;

[0044] 6. Add 0.3kg of flavors and fragrances, 0.2kg of edible salt and 1kg of baking soda, adjust the pH value of the product to 6.5...

Embodiment 3

[0048] A kind of Yuanmai beverage, the production process is as follows:

[0049] 1. Yuan wheat flour pretreatment: 50kg yuan wheat flour is sieved with 80-mesh sieve, dissolved in demineralized water according to the ratio of 1:13, heated to 88°C, and kept warm for 23 minutes, then passed through a colloid mill for one time, and set aside;

[0050] 2. Dry mix 3kg of gellan gum, 30kg of sugar and 3kg of honey evenly, stir and add to hot water at 88°C, and continue to stir and dissolve for 26 minutes until no particles are visible to the naked eye;

[0051] 3. Slowly add the pretreated barley pulp to the colloid solution in step 2 under stirring, and continue stirring until the solution is evenly mixed;

[0052] 4. After replenishing water and set the volume to nearly 1000kg, heat to about 65°C for vacuum degassing;

[0053] 5. 65~75℃, 15~18Mpa, homogeneous;

[0054] 6. Add 0.01kg of flavors and fragrances, 0.2kg of edible salt and 0.1kg of baking soda, adjust the pH value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com