Processing method of round timber

A processing method and technology of round wood, which is applied in the field of round wood processing technology and operation, can solve the problems of low wood yield and low wood utilization rate, and achieve the effects of high wood yield, high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Material selection and truncation: adopt eucalyptus logs with a diameter of 5 cm (error ± 1 cm), and cut them to a length of 35 cm (error ± 5 cm).

[0060] (2) round. Use a rotary cutter to round the log to remove branches, knots and bark on the surface of the log; the thickness of the round is 3 mm.

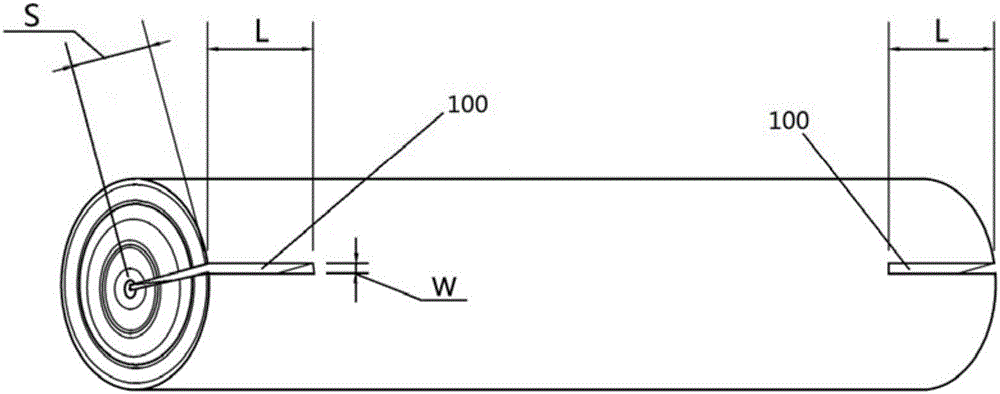

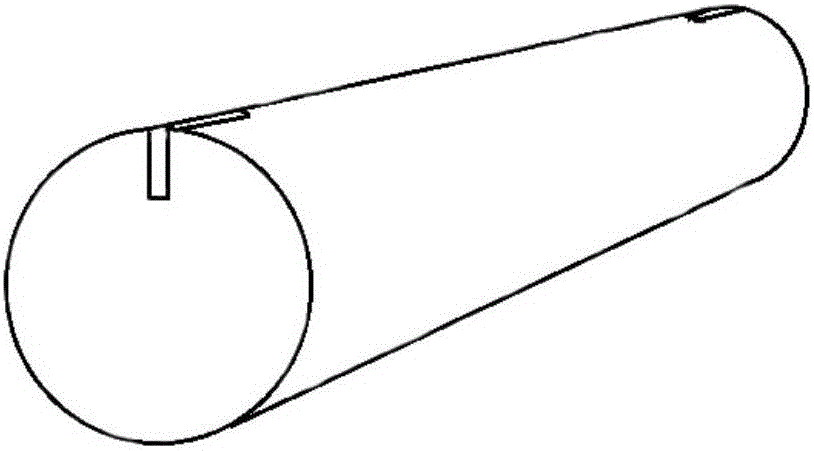

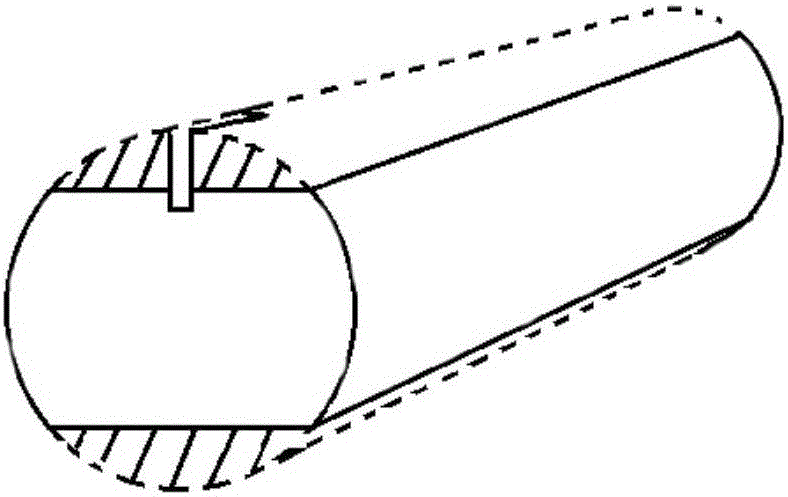

[0061] (3) Open the stress relief groove 100 . A stress relief groove 100 with a length of 5 centimeters, a width of 2.5 millimeters and a depth of 2 centimeters is formed at both ends of the round material in the direction of the pith center.

[0062] (4) Dry naturally. Choose a place with good ventilation and no sunlight exposure for natural drying. When the moisture content of the log is 35%, the natural drying is completed.

[0063] (5) Kiln drying. The drying process includes:

[0064] a) When the moisture content of the round wood is 30% to 35%, keep the dry bulb temperature in the kiln at 45°C and the wet bulb temperature at 42°C;

[0065] b) When the mo...

Embodiment 2

[0072] (1) Material selection and cutting: use fir logs with a diameter of 10 cm (error ± 1 cm), and cut them into logs with a length of 50 cm (error ± 5 cm).

[0073] (2) round. Use a rotary cutter to round the log to remove branches, knots, and bark on the surface of the log; the thickness of the round is 4 mm.

[0074] (3) Open the stress relief groove 100 . A stress relief groove 100 with a length of 6 centimeters, a width of 4 millimeters and a depth of 5 centimeters is formed at both ends of the round material in the direction of the pith center.

[0075] (4) Dry naturally. Choose a place with good ventilation and no sunlight exposure for natural drying. When the moisture content of the log is 40%, the natural drying is completed.

[0076] (5) Kiln drying. The drying process includes:

[0077] a) When the moisture content of the round wood is 30% to 40%, keep the dry bulb temperature in the kiln at 47°C and the wet bulb temperature at 43°C;

[0078] b) When the mo...

Embodiment 3

[0086] (1) Material selection and cutting: use pine logs with a diameter of 16 cm (error ± 1 cm), and cut them into logs with a length of 60 cm (error ± 5 cm).

[0087] (2) round. Use a rotary cutter to round the log to remove branches, knots and bark on the surface of the log; the thickness of the round is 5 mm.

[0088] (3) Open the stress relief groove 100 . A stress relief groove 100 with a length of 6 centimeters, a width of 5 millimeters and a depth of 8 centimeters is opened at both ends of the round material in the direction of the pith center.

[0089] (4) Dry naturally. Choose a place with good ventilation and no sunlight exposure for natural drying. When the moisture content of the log is 45%, the natural drying is completed.

[0090] (5) Kiln drying. The drying process includes:

[0091] a) When the moisture content of the round wood is 30% to 45%, keep the dry bulb temperature in the kiln at 49°C and the wet bulb temperature at 45°C;

[0092] b) When the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com