High-strength wear-proof composite material and preparation method thereof

A composite material and high-strength technology. It is applied in the field of composite materials with high strength and wear resistance. It can solve the problems of insufficient strength and load-bearing capacity, large connection gaps, and complex molding, and achieve excellent sliding wear resistance. , good chemical stability, good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

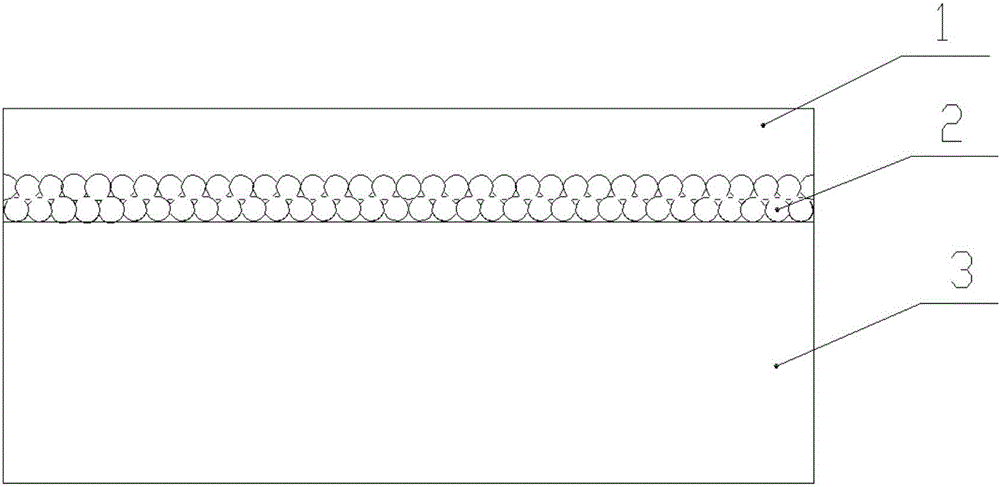

Image

Examples

example 1

[0029] Prepare as follows:

[0030] (1) Spread the 60-100 mesh spherical bronze powder flatly on the 1.8mm wall thickness SPCC steel plate, the thickness of the copper powder is 0.4mm, the sintering temperature is 900℃, the holding time is 30 minutes, nitrogen protection, and sintering to obtain a strong composite copper Powder board.

[0031] (2) Mix and dry each component of the material of the plastic layer according to the following mass percentages: PEEK (polyether ether ketone) 65%, PTFE (polytetrafluoroethylene) 10%, PI (polyimide) 24%, Graphite 1%.

[0032] (3) Put the copper powder board in the appeal step (1) into the cavity of the hot pressing mold as an insert, and then spread the plastic layer mixture in the appeal step (2) on the copper powder layer. The thickness is 2mm higher than the copper powder layer, pressurized to 1.5MPa, the cavity is heated to 330°C and kept at a constant temperature for 25 minutes, then pressurized to 7MPa, and heated to 360°C, then kept at...

Embodiment 2

[0035] (1) Spread the 60-100 mesh spherical bronze powder on a 3.0mm wall thickness SPCC steel plate. The thickness of the copper powder is 0.3mm, the sintering temperature is 880℃, the holding time is 40 minutes, nitrogen protection, and sintering to obtain a strong composite copper. Powder board.

[0036] (2) Mix and dry each component of the material of the plastic layer according to the following mass percentages: PEEK (polyether ether ketone) 55%, PTFE (polytetrafluoroethylene) 13%, PI (polyimide) 30%, Graphite 2%.

[0037] (3) Put the copper powder board in the above step (1) into the cavity of the hot pressing mold as an insert, and then spread the plastic layer mixture in the above step (2) on the copper powder layer. The thickness is 2.5mm higher than the copper powder layer, pressurized to 2MPa, the cavity is heated to 350°C and kept at a constant temperature for 30 minutes, then pressurized to 8MPa, and heated to 375°C, then kept at a constant temperature for 40 minutes...

Embodiment 3

[0040] (1) Spread the 60-100 mesh spherical bronze powder on the 0.5mm wall thickness SPCC steel plate, the thickness of the copper powder is 0.35mm, the sintering temperature is 850℃, the holding time is 35 minutes, nitrogen protection, and sintering to obtain a strong composite copper Powder board.

[0041] (2) Mix and dry each component of the material of the plastic layer according to the following mass percentages: PEEK (polyether ether ketone) 69%, PTFE (polytetrafluoroethylene) 15%, PI (polyimide) 15%, Graphite 1%.

[0042] (3) Put the copper powder board in the above step (1) into the cavity of the hot pressing mold as an insert, and then spread the plastic layer mixture in the above step (2) on the copper powder layer. The thickness is 3mm higher than the copper powder layer, pressurized to 1MPa, the cavity is heated to 320°C and kept at a constant temperature for 20 minutes, then pressurized to 6MPa, and heated to 370°C, then kept at a constant temperature for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com