Method for preparing net-size C/C composite heat-preservation hard felt

A technology of composite heat preservation and net size, which is applied in the field of composite hard felt preparation, can solve the problems of high manufacturing cost, unstable product state, and poor integrity, and achieve the effects of ensuring flatness, shortening the preparation cycle, and reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) According to the product specifications, first prepare the thickness gauge, the thickness gauge size is 40±0.02mm, and the withstand pressure is ≥2MPa;

[0034] (2) Select polyacrylonitrile-based carbon fiber to prepare 10mm carbon felt and 6K carbon cloth, and the volume density of carbon felt is 0.10g / cm 3 , 6K carbon cloth surface density is 280g / m 2 , the preparation method is plain weave;

[0035] (3) Selecting phenolic resin with a solid content of 45% and a viscosity of 12mpa.s as the impregnating solution, flexible graphite paper with a thickness of 0.6 mm as the surface treatment, roughening the surface of the flexible graphite paper and covering it with a well-shaped gas path;

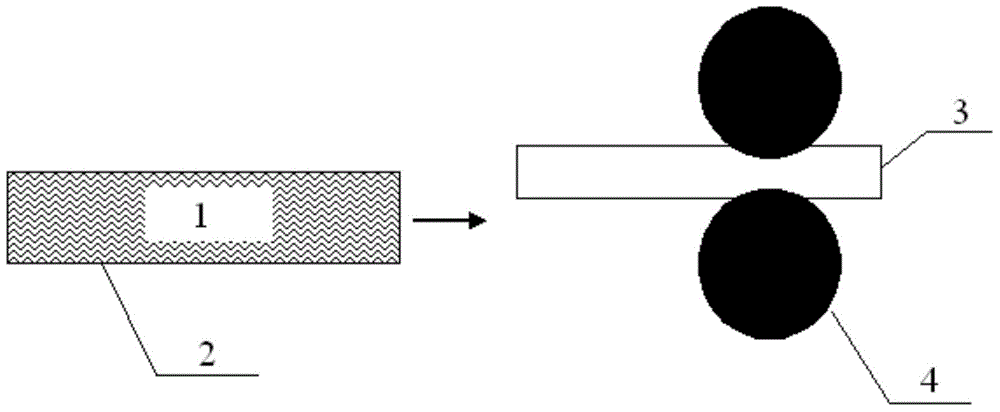

[0036] (4) Use dipping equipment, if attached figure 1 As shown, let the carbon felt pass through the dipping tank first, and then complete the dipping process under the traction of the double sticks. The distance between the double sticks is controlled to be 50% of the thickness...

Embodiment 2

[0041] (1) According to the product specifications, first prepare the thickness gauge, the thickness gauge size is 20±0.02mm, and the withstand pressure is ≥2MPa;

[0042] (2) Select polyacrylonitrile-based carbon fiber to prepare 10mm carbon felt and 6K carbon cloth, and the volume density of carbon felt is 0.15g / cm 3 , 6K carbon cloth surface density is 280g / m 2 , the preparation method is plain weave. ;

[0043] (3) Selecting phenolic resin with a solid content of 45% and a viscosity of 12mpa.s as the impregnating solution, flexible graphite paper with a thickness of 0.6 mm as the surface treatment, roughening the surface of the flexible graphite paper and covering it with a well-shaped gas path;

[0044] (4) Use dipping equipment, if attached figure 1 As shown, let the carbon felt pass through the dipping tank first, and then complete the dipping process under the traction of the double sticks. The distance between the double sticks is controlled to be 40% of the thickn...

Embodiment 3

[0049] (1) According to the product specifications, first prepare the thickness gauge, the thickness gauge size is 65±0.02mm, and the withstand pressure is ≥2MPa;

[0050] (2) Select polyacrylonitrile-based carbon fibers to prepare 5mm and 10mm carbon felts and 6K carbon cloths, and the volume density of carbon felts is 0.20g / cm 3 , 6K carbon cloth surface density is 280g / m 2 , the preparation method is plain weave. ;

[0051](3) Selecting phenolic resin with a solid content of 45% and a viscosity of 12mpa.s as the impregnating solution, flexible graphite paper with a thickness of 0.6 mm as the surface treatment, roughening the surface of the flexible graphite paper and covering it with a well-shaped gas path;

[0052] (4) Use dipping equipment, if attached figure 1 As shown, let the carbon felt pass through the dipping tank first, and then complete the dipping process under the traction of the double sticks, and control the distance between the double sticks to be 70% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Cloth density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com