Rubber peptizer SS preparation method

A technology of rubber peptizer and oxidant, which is applied in the preparation of organic compounds, chemical instruments and methods, hydrogenated polysulfide/polysulfide preparation, etc. It can solve the problems of complex process, expensive raw materials, and many by-products. Achieve the effect of simple process, price advantage and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

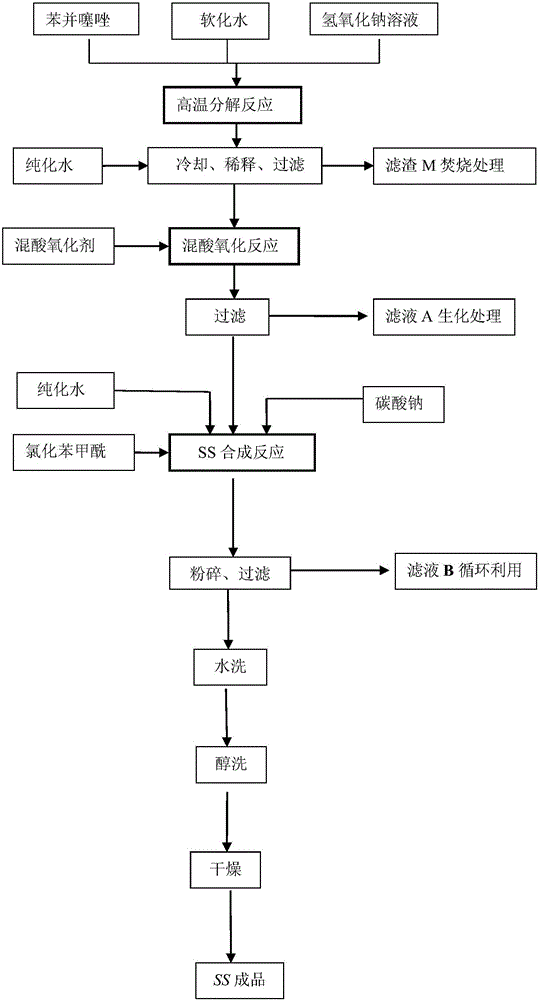

[0040] A preparation method of rubber peptizer SS, the technological process of its preparation is as follows:

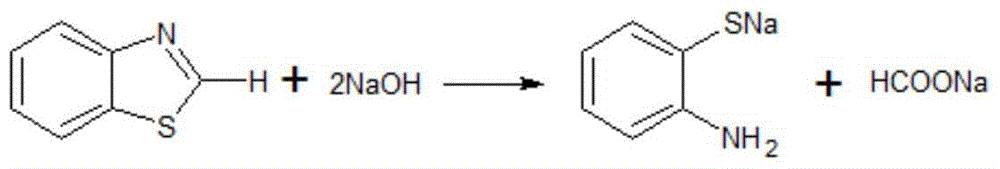

[0041] 1) Decomposition reaction of benzothiazole and sodium hydroxide: put 673.6g (8.42mol) of 50% sodium hydroxide solution and 115g of demineralized water into the reaction kettle in turn, start stirring and dissolving, then add 495g (3.66mol) of benzothiazole, Heat the oil bath to 126°C, react for 5.0 hours, cool down to 100°C, add 600ml of purified water, filter, and get the filter residue M to be incinerated in an incinerator, and the filtrate is transferred to a reaction kettle, and the temperature is controlled at 35-40°C;

[0042] (2) Preparation of 2,2'-diphenylamine disulfide (DS) by oxidation: Add 1118.6ml of mixed acid oxidant dropwise at 35-40°C to the solution in step (1), and the oxidation reaction takes 4.0-4.5 h, the dropwise addition is completed, stirred and reacted for 2.0 hours after heat preservation, centrifuged, the filter cake DS is used fo...

Embodiment 2

[0049] A preparation method of rubber peptizer SS, the technological process of its preparation is as follows:

[0050] (1) Decomposition reaction of benzothiazole and sodium hydroxide: 600.24g (7.5mol) of 50% sodium hydroxide solution and 98g of demineralized water are put into the reaction kettle in turn, and after stirring and dissolving, add 495g (3.66mol) of benzothiazole , heated in an oil bath to 126°C, reacted for 5.0 hours, cooled to 100°C, added 600ml of purified water, filtered, and the obtained filter residue M was put into an incinerator for incineration, and the filtrate was transferred into a reaction kettle, and the temperature was controlled at 35-40°C;

[0051] (2) Preparation of 2,2'-diphenylamine disulfide (DS) by oxidation: Add 990ml of mixed acid oxidant dropwise to the solution in step (1) at 35-40°C, and the oxidation reaction takes 4.0-4.5h After the dropwise addition is completed, stir and react for 2.0 hours after heat preservation, centrifugal separ...

Embodiment 3

[0058] A preparation method of rubber peptizer SS, the technological process of its preparation is as follows:

[0059] (1) Decomposition reaction of benzothiazole and sodium hydroxide: 614.4g (7.68mol) of 50% sodium hydroxide solution and 110.6g of demineralized water are put into the reaction kettle successively, and after stirring and dissolving, add 495g (3.66mol) of benzothiazole ), heated in an oil bath to 126°C, reacted for 5.0 hours, cooled to 100°C, added 600ml of purified water, filtered, and the filter residue M was incinerated in an incinerator, and the filtrate was transferred to a reaction kettle, and the temperature was controlled at 35-40°C;

[0060] (2) Preparation of 2,2'-diphenylamine disulfide (DS) by oxidation: Add 1020ml of mixed acid oxidant dropwise at 35-40°C to the solution in step (1), and the oxidation reaction takes 4.0-4.5h After the dropwise addition is completed, stir and react for 2.0 hours after heat preservation, centrifugal separation, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial melting point | aaaaa | aaaaa |

| Initial melting point | aaaaa | aaaaa |

| Initial melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com