Preparation method of low-angle-dependence red polystyrene colloidal crystal film

A technology of colloidal crystals and polystyrene, applied in the field of photonic crystal structural color preparation, can solve the problem of not being able to obtain a single red color, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

[0019] The method for preparing a red polystyrene colloidal crystal film with low angle dependence of the present invention includes the following steps:

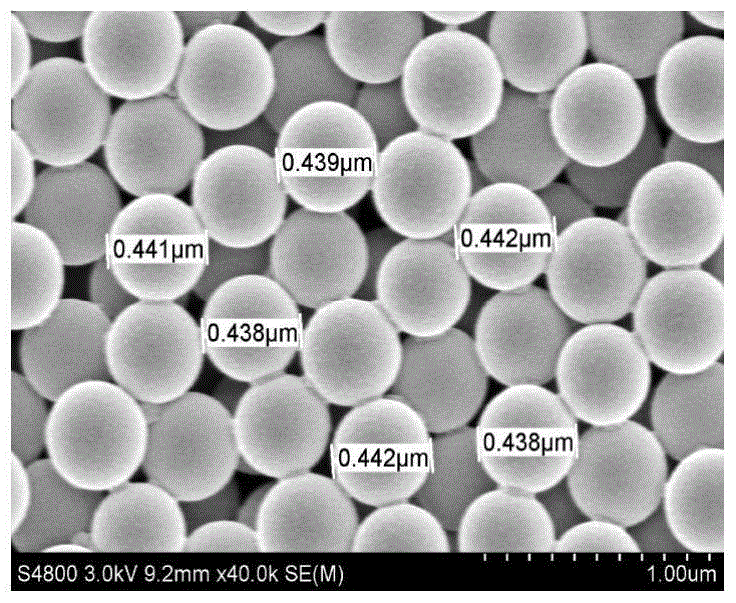

[0020] (1) Prepare monodisperse and uniform PS microsphere mother liquor with an average particle size of 440±10nm by emulsion polymerization, dilute it to a PS microsphere concentration of 0.1-0.5wt% with deionized water as a solvent The emulsion is placed in 30-100mL glassware for ultrasonic dispersion for 30-60min.

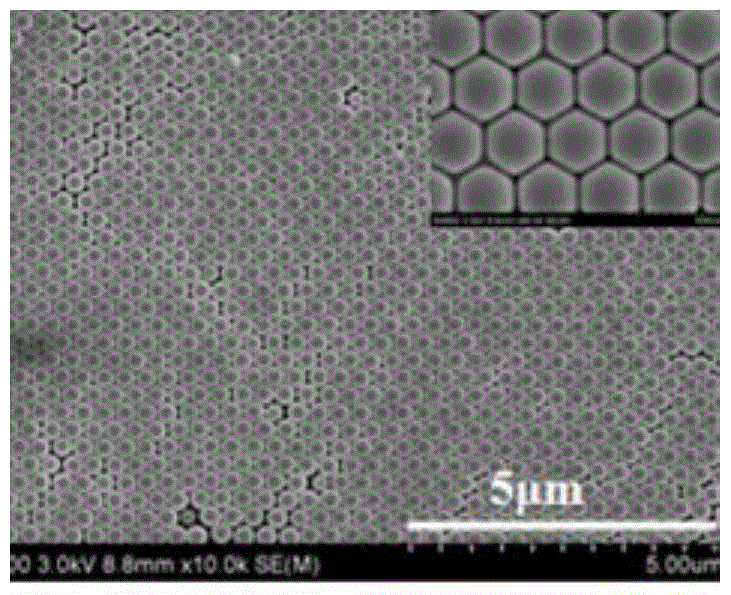

[0021] (2) Clean the substrate with deionized water, then ultrasonically clean it in ethanol and deionized water for 30-90 minutes, and then dry it for later use. The cleaned substrate is vertically fixed in the ultrasonically dispersed PS emulsion, and placed in an oven for 9-12 hours to slowly dry, and the drying temperature is controlled to be 40-65°C.

[0022] (3) Put the assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com