Food-grade TPE material and preparation technology thereof

A food-grade, raw material technology, applied in the field of TPE materials, can solve problems such as toxic and side effects, and achieve stable performance, consistent physical properties, and less frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

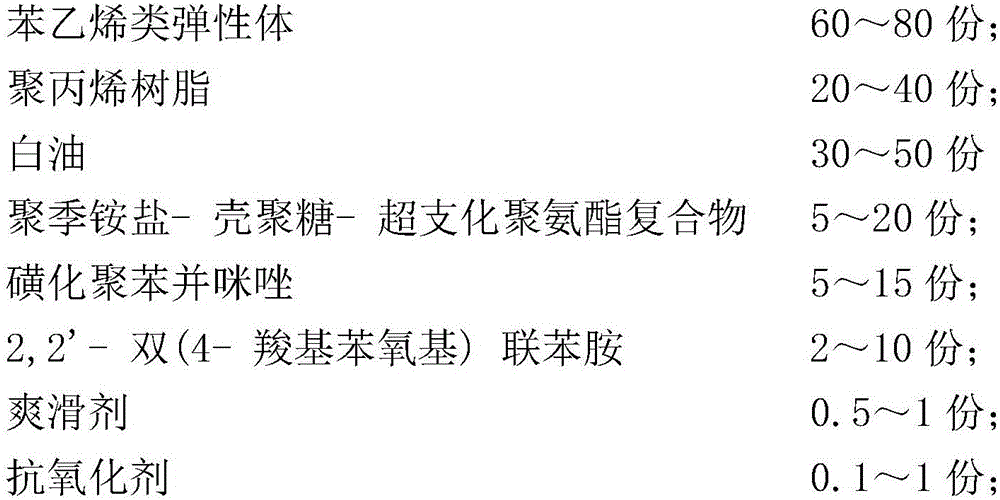

[0032] The food-grade TPE material is characterized in that it contains the following raw materials in weight ratio:

[0033]

[0034] The polyquaternium salt-chitosan-hyperbranched polyurethane composite is obtained by first modifying chitosan with polyquaternium salt, and then modifying the hyperbranched polyurethane with the obtained modified chitosan.

[0035] Its preparation method is:

[0036] (1) Ingredients; configure the raw materials according to the formula of the above-mentioned food-grade TPE material; use a low-speed horizontal mixing tank to mix evenly at low speed; (2) Extrude; send the mixture obtained in step (1) into the twin-screw extruder in turn and single-screw extruder, extruding; (3) pelletizing; the material extruded in step (2) is sent to pelletizing machine for pelletizing; (4) cooling; after step (3) pelletizing is completed cooling the material; (5) dehydrating; sending the cooled material in step (4) to a centrifugal dehydrator for dehydratio...

Embodiment 2

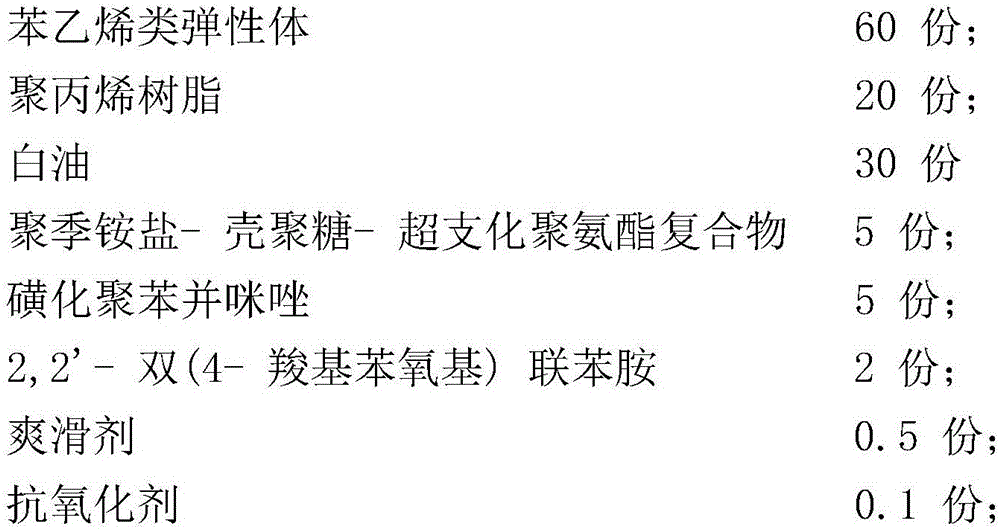

[0039] The food-grade TPE material is characterized in that it contains the following raw materials in weight ratio:

[0040]

[0041]

[0042] The polyquaternium salt-chitosan-hyperbranched polyurethane composite is obtained by first modifying chitosan with polyquaternium salt, and then modifying the hyperbranched polyurethane with the obtained modified chitosan.

[0043] Its preparation method is:

[0044](1) Ingredients; configure the raw materials according to the formula of the above-mentioned food-grade TPE material; use a low-speed horizontal mixing tank to mix evenly at low speed; (2) Extrude; send the mixture obtained in step (1) into the twin-screw extruder in turn and single-screw extruder, extruding; (3) pelletizing; the material extruded in step (2) is sent to pelletizing machine for pelletizing; (4) cooling; after step (3) pelletizing is completed cooling the material; (5) dehydrating; sending the cooled material in step (4) to a centrifugal dehydrator for...

Embodiment 3

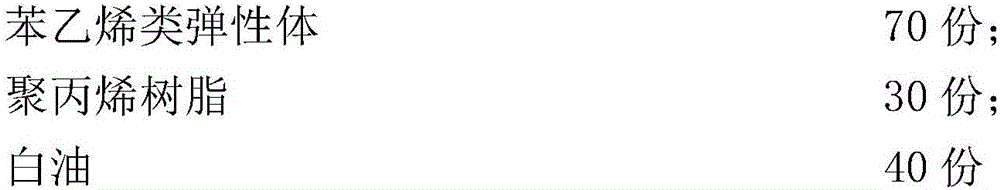

[0047] The food-grade TPE material is characterized in that it contains the following raw materials in weight ratio:

[0048]

[0049] The polyquaternium salt-chitosan-hyperbranched polyurethane compound is obtained by first modifying chitosan with polyquaternium salt, and then modifying the hyperbranched polyurethane with the obtained modified chitosan.

[0050] Its preparation method is:

[0051] (1) Ingredients; configure the raw materials according to the formula of the above-mentioned food-grade TPE material; use a low-speed horizontal mixing tank to mix evenly at low speed; (2) Extrude; send the mixture obtained in step (1) into the twin-screw extruder in turn and single-screw extruder, extruding; (3) pelletizing; the material extruded in step (2) is sent to pelletizing machine for pelletizing; (4) cooling; after step (3) pelletizing is completed cooling the material; (5) dehydrating; sending the cooled material in step (4) to a centrifugal dehydrator for dehydration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com