Crystal swimming paint and using method thereof

A technology of coating and crystal swimming, which is applied in coating, sustainable manufacturing/processing, chemical industry, etc. It can solve the problems of short service life, difficult cleaning and easy scratching of crystal coating, so as to achieve good self-cleaning and prevent Oxidation and acid-base corrosion, strong non-stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

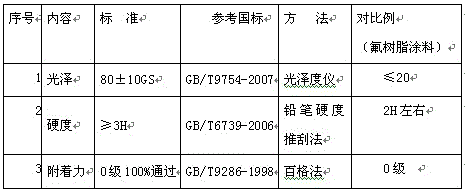

Image

Examples

Embodiment 1

[0039] Embodiment 1: The embodiment of the present invention includes the following components in mass percentage: including 34% inorganic modified methacrylate, 25% hydroxymethacrylic resin, 15% isopropanol, 12% n-butanol , 12% ethanol, 1% polyether modified siloxane and 1% polysiloxane.

[0040] The above components were sequentially added into the disperser and mixed at a speed of 500 rpm for 30 minutes.

[0041] A method for using a crystal coating, comprising the following steps:

[0042] Paint equipment:

[0043] S10: Prepare each component raw material according to the above mass percentage;

[0044] S11: adding the components prepared in step S10 into the disperser in sequence and mixing at a speed of 500 rpm for 30 minutes to obtain the coating;

[0045] S12: Use a 300-mesh filter to remove coarse crystals in the paint;

[0046] Workpiece pre-processing:

[0047] S20: Clean the surface of the aluminum profile workpiece to remove stains and oxides attached to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com