Clostridium beijerinckii strain and applications thereof

A technology of Clostridium beijerinckii and microbial strains, applied in the field of microorganisms, can solve problems such as competition with people for food and food shortages, and achieve the effects of good stability and increased total solvent output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The ultraviolet mutagenesis screening process of embodiment 1 Clostridium beijerinckii CM20 bacterial strain

[0027] Clostridium beijerinckii Clostridium beijerinckii NCIMB8052 (purchased from the British National Center for Industrial, Marine and Food Culture Collection) was subjected to ultraviolet mutagenesis, and was screened on a starch-glucose solid plate to obtain high-activity strains, and then screened by anaerobic fermentation to obtain target strains with high production of butanol, acetone, and ethanol .

[0028] The specific process is as follows: Clostridium beijerinckii NCIMB8052 is the starting strain. First, it is cultivated in P2 (glucose as the substrate) liquid fermentation medium. After growing to the exponential phase, take 600 microliters of bacterial liquid and carry out mutagenesis under anaerobic conditions. The ultraviolet mutagenesis condition is UV : 15W, height: 10cm, time: 2-3min. After the mutagenization, the bacterial solution was ap...

Embodiment 2

[0034] The passage stability of embodiment 2 Clostridium beijerinckii CM20 bacterial strains

[0035] In the P2 fermentation medium with glucose as the carbon source, the passage stability of Clostridium beijerinckii CM20 was detected.

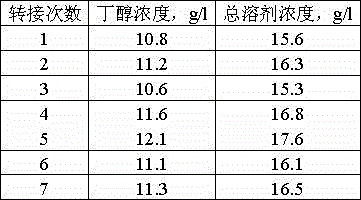

[0036] In the 7 consecutive transfer cultures, CM20 used glucose as the carbon source to produce butanol and the total solvent were relatively stable, and had good passage stability. The specific results are shown in Table 2.

[0037] The passage stability test result of table 2 mutant strain CM20

[0038]

[0039] When glucose was used as the carbon source, the total solvent yield was 15.3-17.6g / l, and the butanol yield was 10.6-12.1g / l, which indicated that the genetic traits of the mutant strain CM20 were stable.

Embodiment 3

[0040]Sequence identification and bacterial strain identification of embodiment 3 mutant strain CM2016sRNA

[0041] Cultivate the mutant strain CM20 in the P2 fermentation medium with glucose as the carbon source, spread the plate during the logarithmic growth phase, and obtain a single clone, pick a single clone into a PCR tube with a sterile toothpick as a PCR template, and perform 16sRNA sequence expansion and primers Use universal primers, 27F: AGAGTTTGATCMTGGCTCAG and 1492r: TACGGYTACCTTGTTACGACTT. The PCR cycle conditions are: 95°C, 10min; 95°C, 20s; 55°C, 20s; 72°C, 1min; 32 cycles; 72°C, 10min. The amplified bands were sent to Huada Gene Company for sequencing, and the sequences were compared with the NCBI website. The sequences and Clostridium beijerinckii The 16sRNA of NCIMB8052 has 100% similarity, proving that the mutant strain is Clostridium beijerinckii .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com