Method for separating lignin and hemicellulose from papermaking black liquor and recovering lye

A technology for hemicellulose and papermaking black liquor, which is applied in the fields of environmental protection and resource recycling, can solve the problems of not mentioning alkali lignin acidification and recovery, not mentioning alkali liquor recovery and hemicellulose separation and recovery, etc. vegan and hemicellulose purifying, contaminant-removing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this example, 20 liters of poplar alkali papermaking black liquor was taken, and the steps listed in the content of the present invention were used to separate hemicellulose and lignin, and to recover the lye. The specific preparation process is as follows:

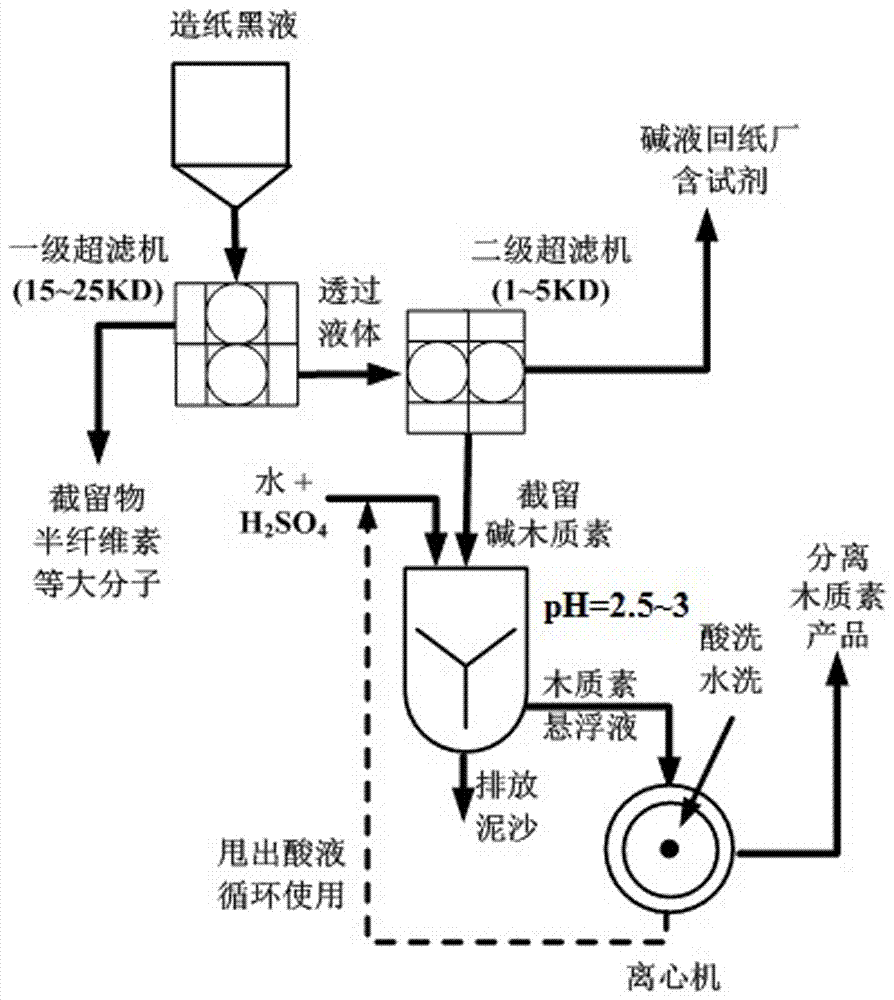

[0042] The method for separating lignin and hemicellulose from papermaking black liquor and reclaiming lye, the preparation process comprises the following steps:

[0043] (1) Put 20 liters of poplar papermaking black liquor in a separation container, remove insoluble suspended matter with a screen, settle for 4 hours after stirring, and then discharge the lower layer of sediment;

[0044] (2) First-stage ultrafiltration of papermaking black liquor to intercept and recover hemicellulose;

[0045] (3) Second-stage ultrafiltration of papermaking black liquor to intercept alkali lignin and recover alkali liquor;

[0046] (4) Acidify the alkali lignin to precipitate lignin; put the retained alkali lignin into the ...

Embodiment 2

[0058] In this example, 20 liters of wheatgrass alkaline papermaking black liquor was taken, and the steps listed in the content of the present invention were used to separate hemicellulose and lignin, and recover the lye. The specific preparation process is as follows:

[0059] (1) Put 20 liters of wheat straw papermaking black liquor in a separation container, remove insoluble suspended matter with a screen, settle for 4 hours after stirring, and then discharge the lower layer of sediment;

[0060] (2) First-stage ultrafiltration of papermaking black liquor to intercept and recover hemicellulose;

[0061] (3) Second-stage ultrafiltration of papermaking black liquor to intercept alkali lignin and recover alkali liquor;

[0062] (4) Acidify the alkali lignin to precipitate lignin; put the retained alkali lignin into the acidifier, add sulfuric acid with a mass concentration of 5-10% for acidification, and keep stirring to adjust to pH=2.5-3. Suspended flocculent lignin appea...

Embodiment 3

[0074] In this example, 20 liters of eucalyptus alkaline papermaking black liquor was taken, and the steps listed in the content of the present invention were used to separate hemicellulose and lignin, and recover the lye. The specific implementation process is as follows:

[0075](1) Put 20 liters of eucalyptus papermaking black liquor in a separation container, remove insoluble suspended matter with a screen, settle for 4 hours after stirring, and then discharge the lower layer of sediment;

[0076] (2) First-stage ultrafiltration of papermaking black liquor to intercept and recover hemicellulose;

[0077] (3) Second-stage ultrafiltration of papermaking black liquor to intercept alkali lignin and recover alkali liquor;

[0078] (4) Acidify the alkali lignin to precipitate lignin; put the retained alkali lignin into the acidifier, add sulfuric acid with a mass concentration of 5-10% for acidification, and keep stirring to adjust to pH=2.5-3. Suspended flocculent lignin appe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com