High-speed semiconductor laser with beam diffusion structure

A diffusion structure and laser technology, applied in semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve the problems of burning semiconductor lasers and laser end face damage, and achieve the effects of suppressing diffusion, good mode matching, and reducing optical power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

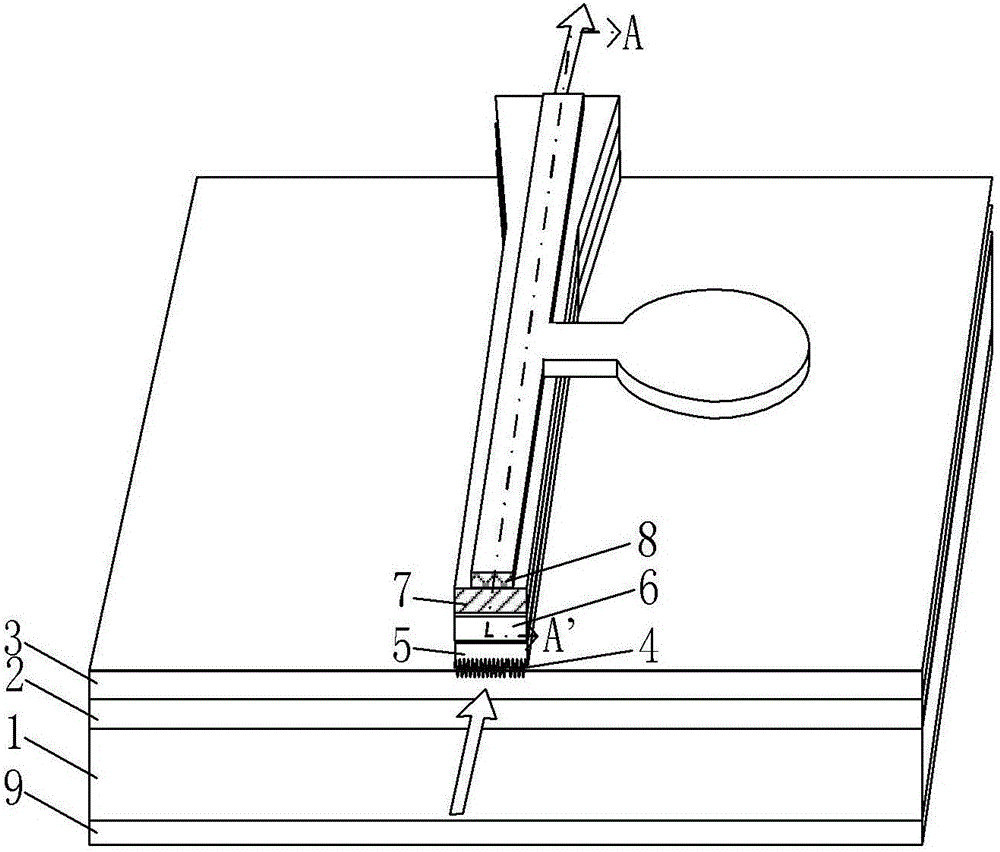

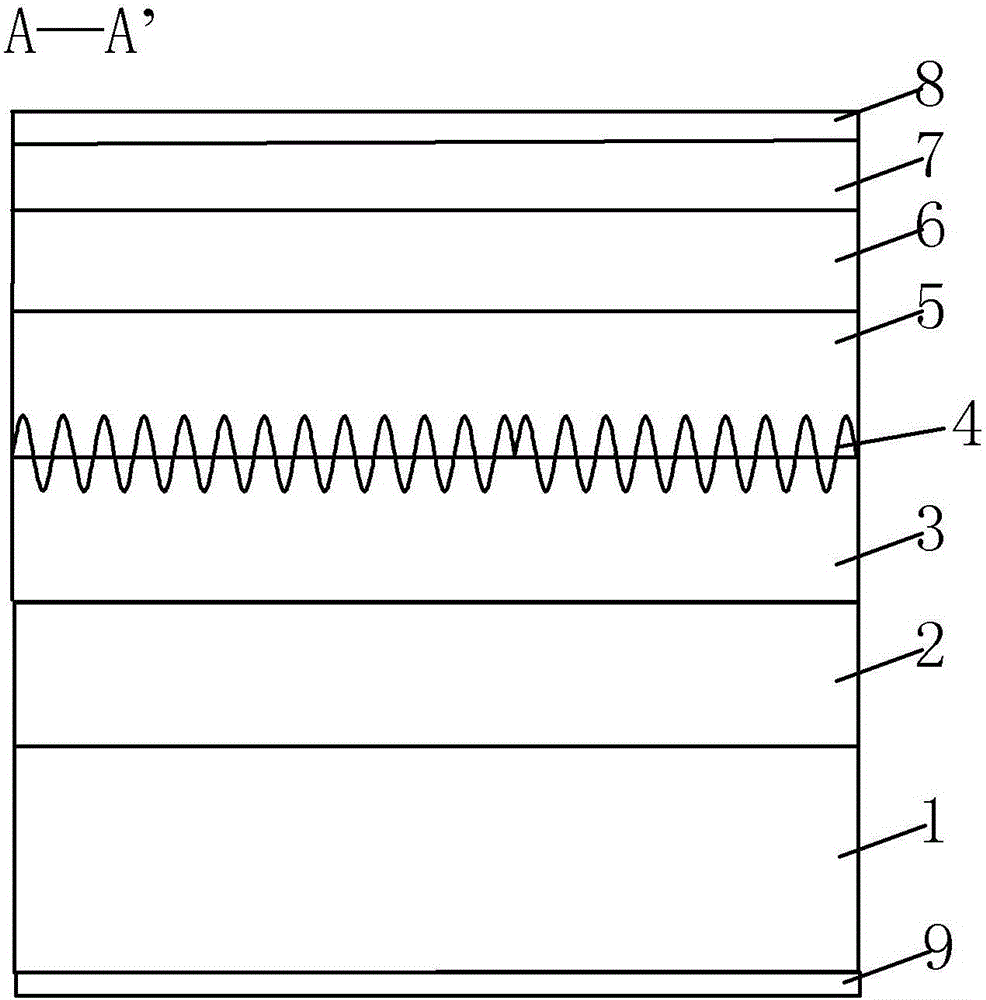

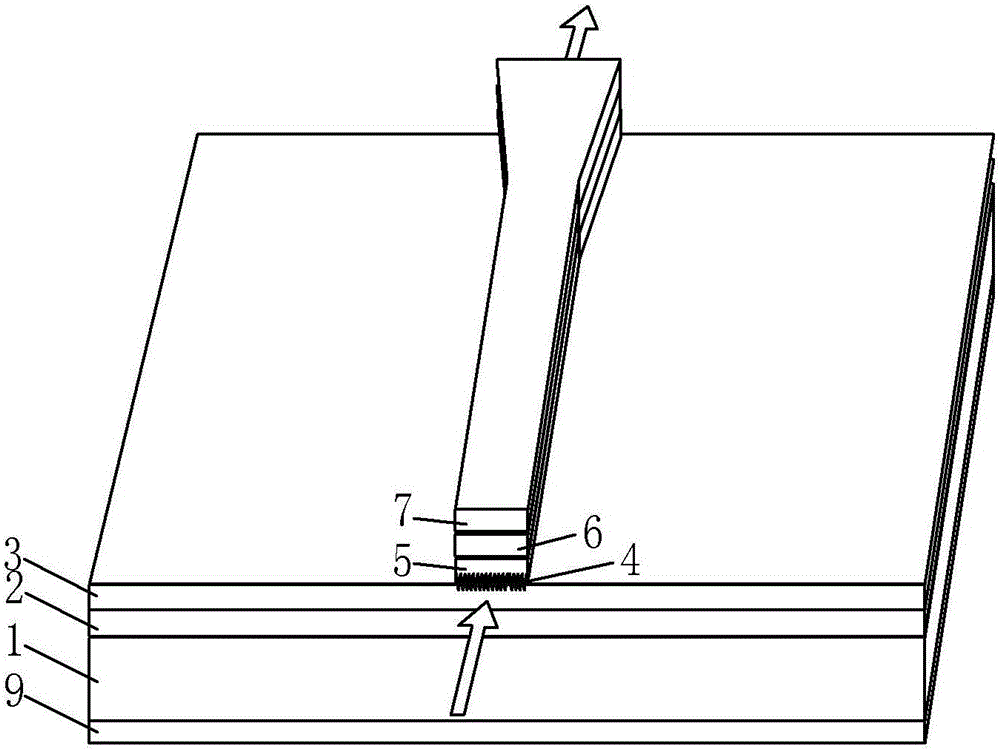

[0024] In order to achieve the above object, the present invention provides a high-speed semiconductor laser with a beam diffusion structure on the light emitting end surface. Specifically, it includes an optical waveguide structure, the optical waveguide structure includes a lower waveguide layer, a multi-quantum well active layer and an upper waveguide layer stacked in sequence from bottom to top, and the multi-quantum well active layer in the multi-quantum well active layer A grating layer is formed on the upper part. The upper waveguide layer is formed as a convex ridge, and has a beam diffusing structure on the side of the light-emitting end surface. The so-called beam diffusion structure means that for a laser with a resonant cavity length L, the projection of the light incident surface and the light exit surface on the Bragg grating has two mutually parallel sides, and the sides of the two mutually parallel sides The lengths are not equal, and the length direction of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com