Plastic covered aortic dissection stent and aortic dissection stent

A technology for aortic dissection and stent grafts, which is applied in the field of medical devices, can solve the problems of dissection breaks and poor plasticity of the proximal end of the stent graft, and achieve enhanced foldability, good radial support strength, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

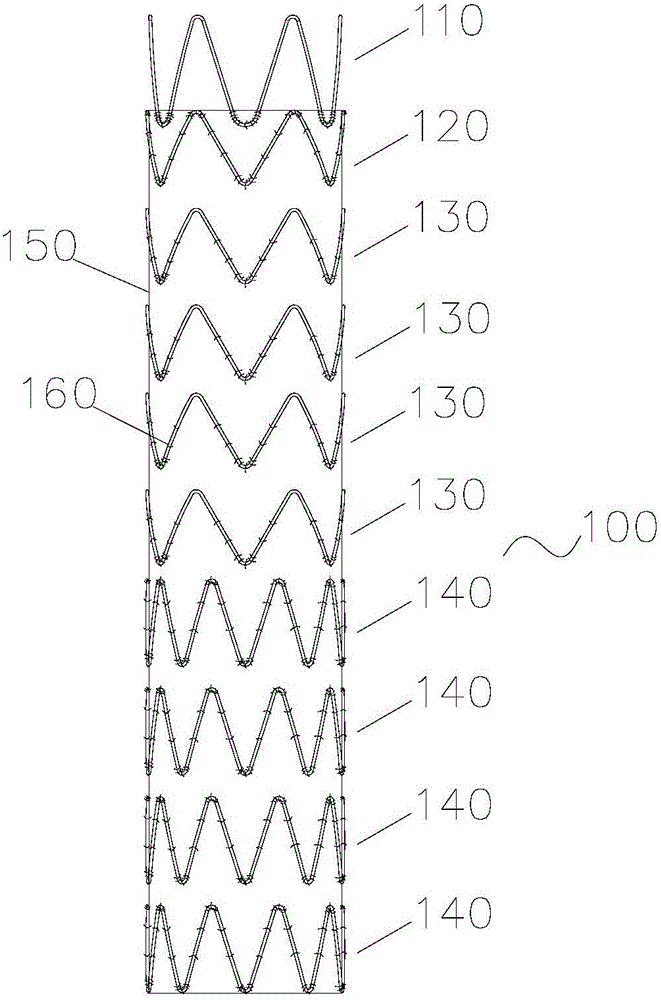

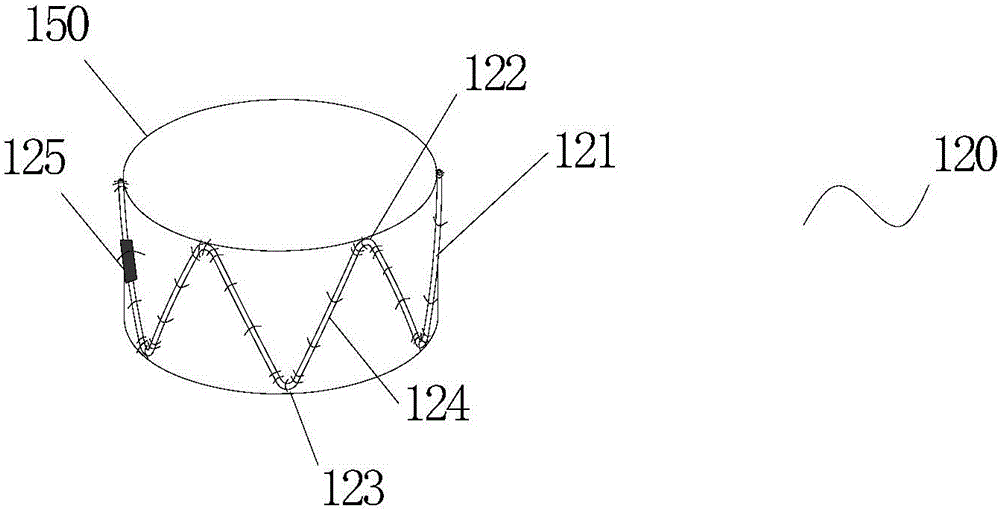

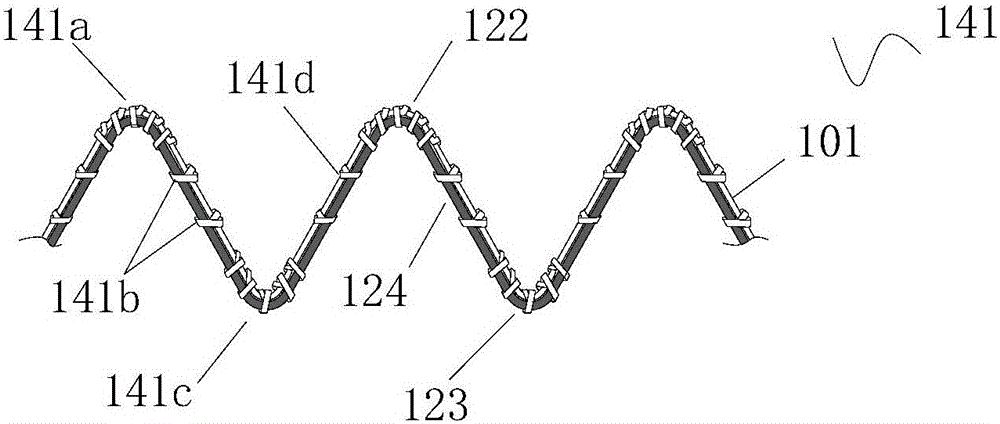

[0068] Such as figure 1 As shown, the stent graft 100 of this embodiment is composed of a tubular membrane 150 and a plurality of independent annular stents sewn on the membrane sequentially along the axial direction. 110 (fourth type of ring stent), ring stent 120 (first type of ring stent), ring stent 130 (second type of ring stent) and ring stent 140 (third type of ring stent).

[0069] The specific quantity of each annular stent depends on the axial length of the stent graft 100 . In this embodiment, there is one annular support 110 , one annular support 120 , four annular supports 130 , and four annular supports 140 .

[0070] The covering film 150 is made of polyester cloth, and the covering film is in the shape of a straight cylinder as a whole, and each ring-shaped support is sutured on the covering film 150 by sutures 160 to form the covering film stent 100 .

[0071] Each annular support undulates along the axial direction in a wave shape while extending in the cir...

Embodiment 2

[0092] Such as Figure 6 As shown, the stent graft 200 of this embodiment is formed by the annular stent 210 , the annular stent 220 , the annular stent 230 , and the annular stent 240 , which are sutured on the membrane 250 by sutures 260 .

[0093] The difference between this embodiment and Embodiment 1 is only that the stitching method between the annular stent 230 and the membrane 250 is different. The material selection, corrugated structure, and manufacturing process of the ring bracket 230 are the same as those of the ring bracket 120 .

[0094] The suture mode of the annular stent 230 and the membrane 250 is as follows: Figure 7a As shown, between adjacent crests 222a and 222b of each annular stent 230, one crest 222b has a stitching point, and the other crest 222a has no stitching point. Such as Figure 7b As shown, from the perspective of the entire stent graft, the peaks 222b with suture points and the peaks 222a without suture points are arranged alternately al...

Embodiment 3

[0097] Such as Figure 8 As shown, the stent graft 300 of this embodiment is composed of a ring stent 310 , a ring stent 320 , a ring stent 330 , and a ring stent 340 , which are sutured on the membrane 350 by sutures 360 .

[0098] The only difference between this embodiment and Embodiment 2 is that the structure of each ring bracket 330 is different from that of the ring bracket 230 .

[0099] Such as Figure 9a As shown, the material selection and manufacturing process of the ring bracket 330 are the same as those of the ring bracket 230 , the only difference is that the wave structure is different, and there is a height difference between the two adjacent wave peaks 322 a and 322 b of each ring bracket 330 .

[0100] The suture method between the annular stent 330 and the membrane 350 is as follows: Figure 9b As shown, there is no stitching point at the upper peak 322a and there is a stitching point 370a at the lower peak 322b. Such as Figure 9c As shown, from the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com